Brand Name: SINDEICE

Model Number: SDE-2.5T

Place of Origin: Guangdong, China (Mainland)

Sindeice great demand flake ice drum 2.5T/24h

SHENZHEN SINDEICE SYSTEMS CO., LTD (Sindeice for short) is a professional manufacturer of ice machines, who has a set of research, design, production, installation, sale and after-sales service. We got a number of experienced experts who engaged in refrigeration and ice machine for many years. With the use of best technology of ice machine and innovative solutions, Sindeice manufactures Flake ice machine, Tube ice machine, Block ice machine, Ice flaker evaporator, Containerized ice plant. Daily capacities are available from 300 kg to 100,000 kg.

Sindeice is sticking to the notion of “great virtue,social commitment”, and the management policy of “integrity, diligence, innovation and mutual benefit”.Sindeice strives to enter into international market.

Characteristics of Flake Ice

With the development of society, Ice-making machine have been used more and more in various field to achieve their processing.

1 , Supermarkets

SINDEICE plate ice is pure in color, luster and good ventilation. It could be used for keep sea food or meat fresh, and show a good view. The smooth and dry surface of plate ice can avoid scratching the food.

2, Meat processing

Plate ice is widely used in the meat processing. For example, in the processing of making sausage, the high temperature, made by the machine, changes the color and taste of meat. It also brings more bacteria. But if plate ice was added into the ingredients, the color and taste of sausage remains well, and less bacteria.

3,Aquatic Product Processing

For ice can provide adequate moisture, and reduce the temperature, it is widely used in the aquatic product processing, such as ocean-fishing, storage, transport and processing . Mechanical refrigeration systems can only provide cold temperature, but not adequate moisture, it makes the surface of aquatic product air-dry, dehydrated, even frozen. Ice can make the perfect cold environment, keeping aquatic product wet and fresh. Meanwhile, melting ice water can clean the surface of product as well, it takes bacteria and smell away.

4, Poultry Slaughtering House

Food export enterprises have strict standard for each single process. Spiral cooling tank water temperature should be 0℃-4℃. Cold water machine can’t meet the requirement. So lot of ice should be added into the spiral cooling tank to keep water temperature 0℃-4℃.

5, Dairy Food Processing

During the process of yogurt fermentation, artificial refrigeration is used for keep the fermentation temperature under the normal, to control the time, humidity, maintain the biological activity of yogurt. Adding some dusty piece of ice is a good method.

6,Bio-pharmaceutical

In the process of production of bio-pharmaceutical, large quantities of sanitary and clean ice can be added to control reactive temperature, maintain biological vitality and ensure product quality.

7, Ocean-going Fishing

Flake ice machine has wider application in marine fisheries. Scaly ice is so unique to cold storage, transport, process and show seafood. Scaly ice is a practical and economic system to keep seafood fresh, wet and right temperature, without monitor. Scaly ice provide a perfect cold environment. The smooth and dry surface of plate ice can avoid scratching the food. Meanwhile, melting ice water can clean the surface of product as well, it takes bacteria and smell away.

8, Application of Concrete Cooling Projects

Pouring construction of large dams and tall buildings around the world requires the use of temperature control of concrete. In the course of maintenance, large volume of concrete grouted temperature rise 25 degree, concreting volume expansion. But after the course of maintenance, large volume of concrete grouted cools down and reduces dwindles in size, usually leading to cracks in water dykes. Therefore, the initial grouting temperature of concrete should be low enough to ensure the highest temperature of concrete during maintenance does not exceed that determined by design units. Mixing ice and water ,or adding ice directly is the normal way to reduce the temperature. SINDEICE is experienced in the field of application of concrete cooling projects, and we can design concrete bathing plant with ice-making, storage, transport, according to different conditions.

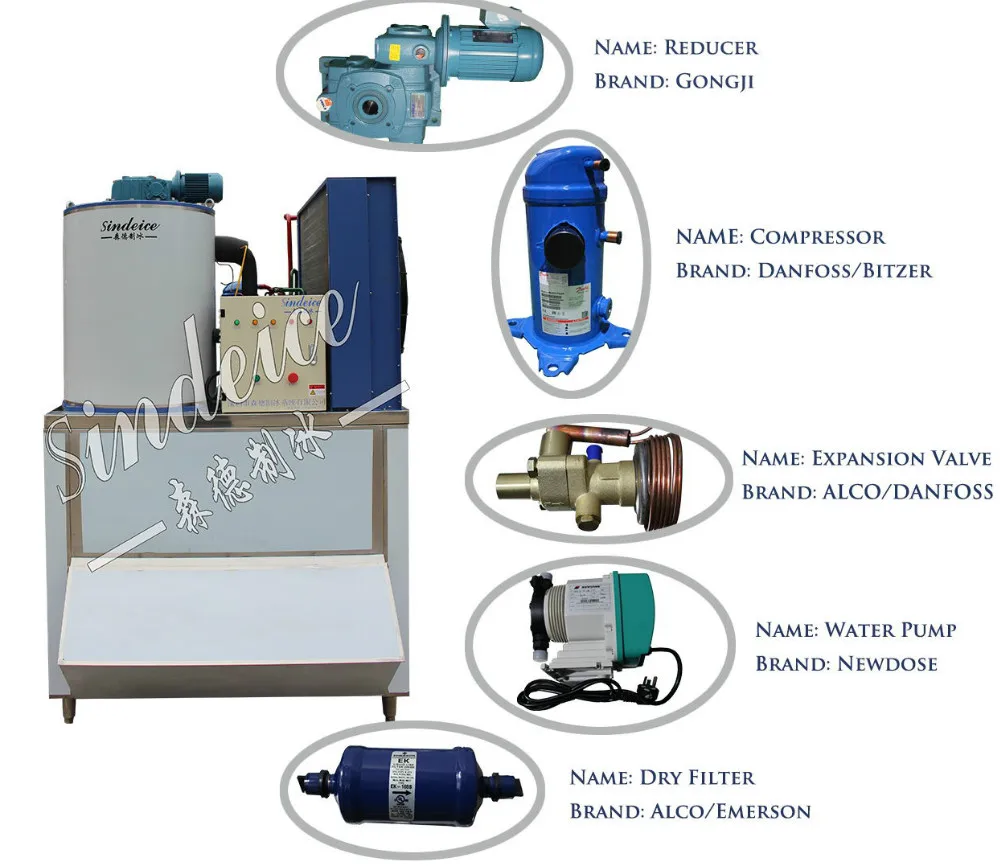

Ice Flaker Evaporator

As the key part of the complete flake ice machine, the ice flaker evaporator plays an important role in making ice. To match the various ice flaker evaporator, you can make different choice about the refrigeration units in different refrigerant (R22, R404a or R717) by yourselves. Before place the order, please let us know which refrigerant you will choose.

Characteristics

1. The ice flaker evaporator use high quality alloy material. Precision welding and surface treatment makes high heat conduction efficient, high strength, longer lifespan.

2. The internally- scraping ice-making mode has been adopted. Under this mode, ice blades scrape ice on the inner wall of the evaporator while the evaporator itself does not move. It reduces the loss of energy as much as possible, guarantees the normal supply of cooling agent as well lower the probability of cooling agent leakage.

3. The stainless steel ice scraper formed without weld. Even by long time scraping, the scrapper keeps still tough, and the ice dropped is sizable with nearly no powder.

Technical Data

*The technical data based on 25℃ ambient temp.18℃ water inlet temp.

*The evaporating temperature is -20℃.

*The condensing temperature is 40℃.

*Power supply: 3P / 380V / 50HZ 3P/220V/60HZ

*Refrigerant:R404a/R22/R507/R717

*Inner wall material: SUS304&Q345 Hard chromium plating

Model |

SDE-2.5T |

Daily Output (TPD) |

2.5 |

Cooling Capacity (KW) |

16 |

Reducer Power (KW) |

0.37 |

Water Pipe |

1/2" |

Weight (KG) |

250 |

Dimension (mm) |

920*850*1150 |

Installation:

1). Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts and operation manual are provided to guide the installation.

2). Installing by SINDEICE engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provide accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.