| Technical Data Sheet of Phenolic Foam Air Duct Panel | ||

| ITEM | UNIT | SPECIFICATION |

| Density | kg/m3 | 60-70 |

| Double side Aluminum thickness | mm | 0.08 |

| Total thickness | mm | 20 |

| Thermal Conductivity | w/m.k | 0.02 |

| Flexural Strength | Mpa | 1 |

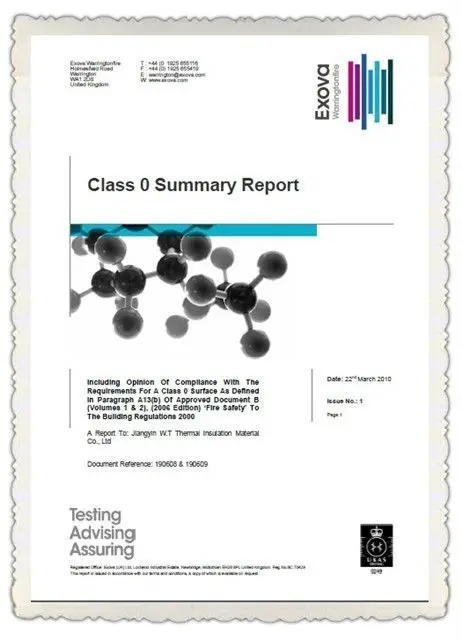

| combustion property | ~ | Class “0” BS Part6&7 |

| Water Absorption Rate | % | 1.9 |

| Max Smoke Density | % | 2 |

| Dimension Change Rate | % | 0.3 |

| Compressive Strength | Mpa | 0.25 |

| Service Temperature | C | -180 to150 |

| Standard Size | mm | 3000(4000)*1200*20 |

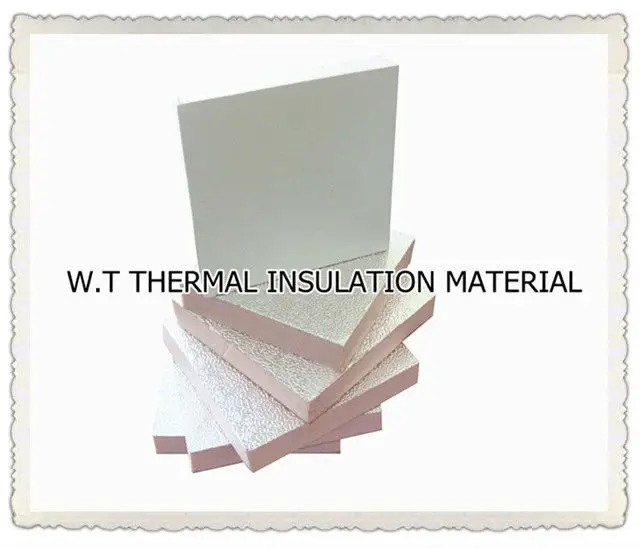

Phenolic duct panel

ISO9001//BS fireproof certificate

Phenolic foam air duct panel is widely used in central air-conditioning ducting of insulation workshops, cleaning rooms, high class buildings, composite cold storages, containers, etc

Its of good appearance, beautiful colors, light weight, high strength and easy installation. Its fire-proof, water-proof and of good insulation property. By using this material, the user can save a lot of costs and time.

Model1:Phenolic foam air duct panel

Size:1200mm(W)*3000/4000mm(L)*20mm (H)

Material:Front and back: 80 microns anti-corrosion coating embossed aluminum foil

Core material: Rigid phenolic foam

(Class0) BS 467 part6&7

Model2:Phenolic foam air duct panel with colored steel

Size: 1200mm(W)*3000/4000mm(L)*20mm (H)

Front: Anti corrosion embossed foil: 80 microns

Back: 200microns colored steel

Core material: Rigid phenolic foam

(Class0) BS 467 part6&7

Model3:Phenolic foam air duct panel with galvanized iron

Size: 1200mm(W)*3000/4000mm(L)*20mm (H)

Front: Anti corrosion embossed foil: 80 microns

Back: 200microns galvanized steel

Core material: Rigid phenolic foam

(Class0) BS 467 part6&7

Model4:Phenolic foam air duct panel with double side steel sheet

Size: 1200mm(W)*3000/4000mm(L)*20mm (H)

Material:Front and back: 200microns color steel/ galvanized steel

Core material: Rigid phenolic foam

(Class0) BS 467 part6&7

Technical Data Sheet of Phenolic Foam pre-insulated air duct panel |

||

ITEM |

UNIT |

SPECIFICATION |

Density |

kg/m3 |

60-65 |

Double side Aluminum thickness |

mm |

0.08 |

Total thickness |

mm |

20 |

Thermal Conductivity |

w/m.k |

0.02 |

Flexural Strength |

Mpa |

1 |

combustion property |

~ |

Glass O (BS 476 part 6&7) |

Water Absorption Rate |

% |

1.9 |

Max Smoke Density |

% |

2 |

Dimension Change Rate |

% |

0.3 |

Compressive Strength |

Mpa |

0.25 |

Service Temperature |

|

-180 to150 |

Standard Size |

mm |

3000(4000)*1200*20 |

Technical Data Sheet of Phenolic Foam Panel with Colored Steel/Galvanized iron |

||

ITEM |

UNIT |

SPECIFICATION |

Density |

kg/m3 |

60-65 kg/m3 |

Aluminum thickness |

mm |

0.08 |

Steel thickness |

mm |

0.2 |

Total thickness |

mm |

20 |

Dimension |

mm |

3000(4000)*1200*20 |

Temperature range |

centigrade |

-180 to 150 |

Thermal conductivity |

w/m.k |

0.020-0.037 |

Firproofing performance |

~ |

Glass O (BS 476 part 6&7) |

Oxygen index |

% |

36-43 |

Grade of smoke density |

~ |

4 SDR |

Water vapor transmission |

g/(m2.24h) |

<1 |

Compression strength |

Mpa |

0.24 |

Flexural strength |

Mpa |

1 |

Air leakage |

% |

<2 |

Material water absorption rate |

% |

<1.5 |

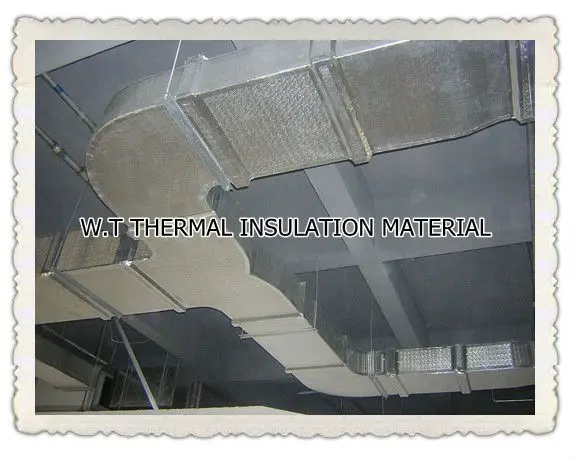

Product Show

Production Equipment

Capacity

Operation pictures

Certification