Brand Name: Peide Rubber ball cleaning device

Model Number: PCE-PD Rubber ball cleaning device

Place of Origin: jiangsu

Condenser Automatic Water Rubber ball cleaning device

Rubber ball cleaning device Introduction

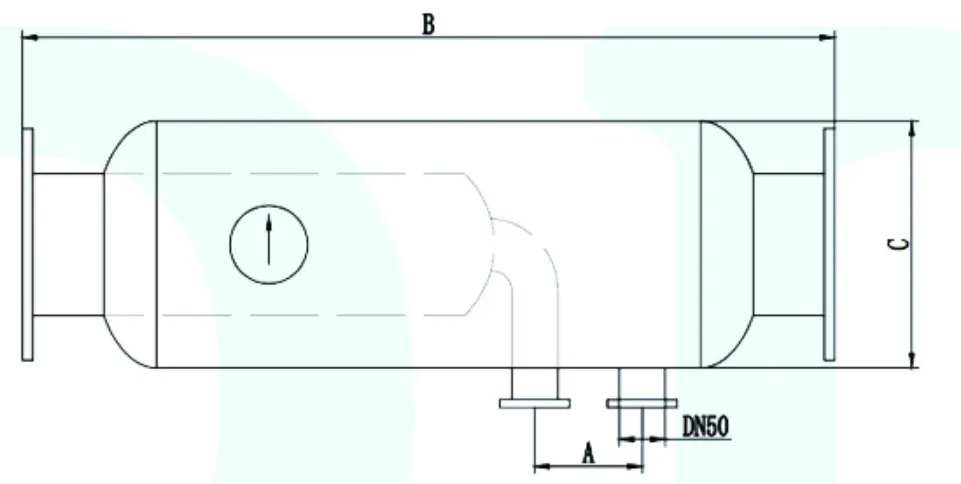

A:Ball outlet

B:Cooling water outlet

C:Ball inlet

D:Cooling water inlet

E:Eonnect With Ball Collector Outlet Water-B

F:Eonnect With Ball Collector Inlet Water-C

Left:Ball Collector

Right:Controller

Condenser rubber ball cleaning device(Hereinafter referred to as the cleaning device) is a kind of physical methods to scrub central air conditioner on condenser the inner wall of the tubes equipment. Central air-conditioning in the process of refrigeration, The refrigerant temperature escalate, must be cooling the refrigerant. A cooling water system is to cool the refrigerant piping system, Condenser is heat exchange device for cooling the refrigerant. cooling water enter into Condenser flowing through the heat exchange inner tubes to out. the cooling system flows through the heat exchange outwall tubes, through the condenser tubes to transfer heat, thus play a role in cooling the refrigerant. Low temperature of cooling water flowing into the condenser and heat exchange cooling system then outflow in high temperature, after a long operation will have a scale in the exchange heat tubes wall, stains precipitation, affect heat transfer efficiency, refrigerant cooling will affect the cooling effect, will increases the central air conditioner mainframe load, reduce the the central air conditioner mainframe life, So will need regular cleaning on the condenser heat exchange inner wall of tubes, thus extending the life of the central air conditioning mainframe.

Scale will not only reduce the heat transfer efficiency, but also increase the water resistance. Prone to corrosion, shorten product life, increase costs. According to the specific working condition, it may have different impact on the cooling system. But for each system are in a state of dynamic equilibrium.

There are many water treatment agent can dissolve or peel off Ca / Mg salt (or base) of a crystalline scale. But the scale of biological sludge is keeping growing, it is the reason that even if done well water, you need to clean annually.

On-line rubber ball cleaning system is a kind of device,which clean inside wall of the condenser tubes by injection and recollect ball. Once the system is installed, you can reduce the cost of water treatment chemicals.

During the actual operation of the cooling water system, there are several kind of wall pollution situations:

1. Scale,hard scale fouling layer, when the condenser temperature is high, and water hardness is high, it’s likely to happen. Conventional water treatment agent is capable of solving this kind of problem.

2. Microorganisms or fungi or algae organic film deposited on the pipe wall, is a kind of loose viscous material, have a greater thermal resistance of the heat exchanger hazard.

3. Impurities and particles,as there is a certain thickness of the laminar layer, the flow rate is small, particularly a mixture of particles and organic adhesions will form into a more stable dirt.

4. Corrosion, acid dissolved in water is the main reason for corrosion, if carbonate ions corrosive ions coexist with other sources, it will enlarge the resistance, thereby shorten the life of the equipment and pipe systems.

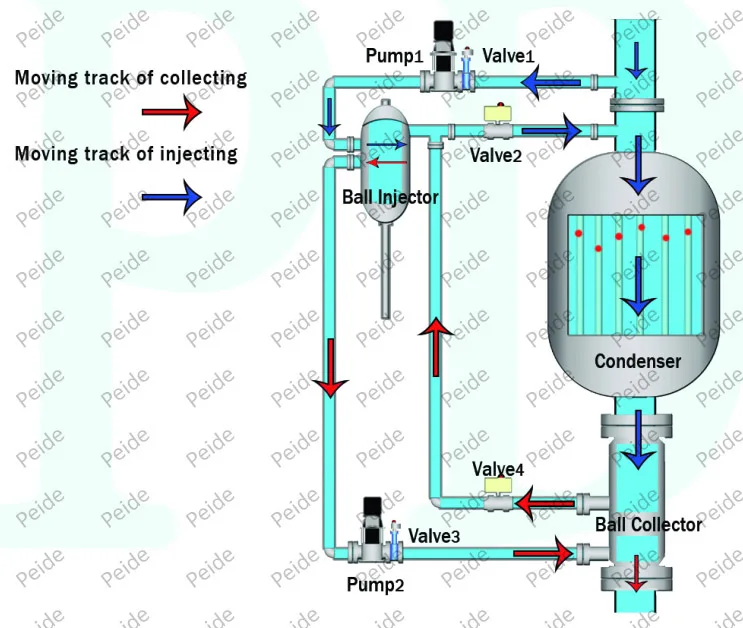

Rubber ball cleaning device Working Principle

1. Inject: When the sponge rubber ball enter into the injector, close the electric valve 3,4, and open the electric valve 1,2 . Start pump 1(injector pump) once the valve is opened to the maximum position, the flow switches will have signal, the pump 1 continues to run, sponge rubber ball will follow the flow and enter into the condenser inlet, under water pressure, ball will squeeze tubes, clean inner wall, after coming from the heat exchange tubes, enter into collector. Cooling water system piping loop continues, thus, a working cycle end.

2. Collect: close electric valve 1,2, stop the pump 1 (injector pump), open the electric valve 3 and 4, when the valve open to the maximum position,start pump 2 (collector pump), flow switches will have signal, pump 2 continue to operate, sponge rubber ball will follow the flow and enter into the injector, ball was stopped by the network, the water back to the cooling water system piping.After all the rubber ball enter into collector, electric valve 3,4 will close, stop the pump 2 (collector pump), thus, a ball collecting process end.

Rubber ball cleaning device Main Composition

Injector: Reserve sponge rubber ball, inject and collect balls.

Sponge Ball: clean the inside wall of heat exchange tube

Ball collector: it will catch the ball when the ball leaves condenser

Control device: automatic control, setting frequency and time of cleaning

Injector pump,valve

Collector pump,valve

Comparison between our design and others

| Peide | Others |

1. Double-pump design, rubber ball does not go through the pump. Without water pump impeller cutting, 50-90% longer life time. |

1. As the rubber ball was cut,Rubbed squeezed by pump impeller, its life-time is only 3-4 months. |

2. No effect on the chilled water temperature to ensure that the cooling efficiency. Saving 1.5-2.5% energy. |

2. The cleaning device and the cooling water pipe has 1.5-2.5% of chilled water. To ensure the cooling effect, the power consumption is increased from 1.5 to 2.5%. |

| 3. Rubber ball through the pipeline using non-folder ball valve. | 3. With ordinary butterfly, it’s easily to scratch, pinch the rubber ball. |

Rubber ball cleaning device Advantage

1. A simple and reliable online cleaning device, with no downtime, can provide long-term thorough and effective cleaning.

2. Automatic control, can set their own cleaning frequency and time.

3. Keep the condenser heat exchanger in the best state, improve the overall efficiency of the unit, reducing operating costs.

4. Reduce central air-conditioning maintenance costs, reduce the use of chemicals, reducing the condenser tubes corrosion.

5. Central air-conditioning compressor to prevent overload of work, extend the service life of the unit.

6. Saving central air-conditioning maintenance downtime on the type of production unit is very favorable.

7. Rubber ball using long period, rubber ball circulation only within the pipeline to avoid damage to the pump on rubber ball.

8. Small size, simple operation, easy installation.

Rubber ball cleaning device Sponge Rubber Ball

As one of the important methods to improve the operating efficiency of the plant, on-line condenser rubber ball cleaning system has become the standard configuration of the plant, rubber ball quality is one of the key elements of the system.

1.Type of Sponge Rubber Ball

·Standard peeling rubber ball

Standard peeling rubber ball is particularly suitable for a variety of condenser brass, it is the most common kind of each plant rubber ball. Rubber balls made of natural rubber and special additives to increase foam. Standard peeling rubber ball can be used in various rubber ball cleaning equipment and water quality. Peeling rubber ball effectively remove biofouling, high viscosity biofouling. For stainless steel and titanium tube heat exchanger tube.

·Ordinary rubber ball

Ordinary rubber ball is with smooth surface, which is mainly used for peeling into standard reusable after peeling rubber ball hit the ground, some of the power plant piping due to deposition was ordered without a hard rubber ball of light, usually used for stainless steel pipe. But the effect of the poor use of brass. Mainly used to remove soft dirt, suitable for cooling water applications, silt, sludge, sediment, etc. applicable to copper heat exchanger.

·Emery rubber ball

Emery rubber ball into a full half Emery Emery rubber ball rubber ball two. Emery rubber ball is suitable for large scale deposition removal of various pipes, but there is damage to the pipe, generally not long-term use, especially brass more caution. Effectively remove hard scale, such as: calcium carbonate. Suitable for steel, stainless steel tube heat exchanger.

2.Specification of sponge rubber ball

ID of copper tube(mm) …… 16 17 …… 24 25 ……

Diameter of ball( mm) …… 15.5 16.5 …… 23.5 24.5 ……

·Appearance and quality standard

1. Uniform pore size;

2. The lack of plastic eyelet, deep no more than 3mm, every ball no more than three, the total lack of plastic area of not more than 10% of the appearance of the area;

3. Rubber ball diameter tolerance ±0.5mm;

4. Ordinary ball Φ16-Φ28, stripping the ball Φ16-Φ27, emery rubber ball Φ16-Φ26.

·Physical Properties

In water of 40 ±1 ℃, soaking for 48 hours, wet density 0.90 ~ 1.20g / cm3 diameter change rate of not more than 10% of the ball diameter. Hard eccentric ball

Temperature greater than 15 degrees, the automatic suspension.

3.How to use

·Normal amount of sponge rubber ball

Condenser cooling process for the number of single-sided 7% -13%, depending on the length of time required cycle time rubber ball, take the lower or upper limit value, or close to, a rubber ball cycle time of 30 seconds in order to define the limits of the general .

·Rubber ball replenishment cycle or replacement cycle

Rubber ball replenishment cycle for rubber ball cleaning system accumulated running seven times, but also different according to the unit to adjust the replenishment cycle specific circumstances.

Rubber ball replacement cycle, according to the domestic sphere to use statistics, the replacement cycle for a total of rubber ball cleaning system runs 60 times.

In addition, soaked in water for some time, individual rubber ball may swell too much, resulting in excessive diameter, in the supplementary and replacement rubber ball, shall be promptly replaced, to prevent cooling blocked.

Ordinary type

| Name | Diameter of ball(mm) | Diameter of ball(mm) |

| Ordinary rubber ball | 16,17,18,19,20 | 21,22,23,24,25,26,28 |

| Emery rubber ball | 12,14,16,17,18,19,20 | 21,22,23,24,25,26,28 |

| Standard peeling rubber ball | 12,14,16,17,18,19,20 | 21,22,23,24,25,26,28,29 |

How to use sponge rubber ball

1: choose the best rubber ball need to consider various factors, it should be conducive to the rubber ball in the net income board recycling, as well as to extend the rubber ball Service life. The most commonly used plastic ball hardness "M" of medium hardness.

2: the number of basic pitching Generally, the number of the basic pitch of each tube is typically about 10% of the condenser every time Cheng Guanzai total. For a multi-polar flash desalination plant, the number of basic pitching for 30-50% of the total each evaporator child organ. Basic pitching amount each system has condensing unit quantity per return pipe and a rubber ball cycle time is determined, the recommended cleaning time is 5 minutes for each tube.

3: rubber ball life cycle frequency and tubes of metal surface conditions has a significant impact on the life of the rubber ball. Based on actual experience, general rubber ball Lifetime is about 4-6 weeks, but depending on the scene with the rubber ball loop frequency can greatly extend the life of the rubber ball. Heat the museum wall junction dirt and corrosion will seriously affect the life of the rubber ball. When the rubber ball badly worn, it should consider using emery ball to smooth rough metal surfaces.

4: The rubber ball rubber ball storage should be stored in a cool dry place, away from direct sunlight and stress.

Application of sponge rubber ball

Water temperature: up to 140 ℃

Applicable pipe: brass, stainless steel, titanium tube

Rubber Ball features: soft, soft, medium and hard, hard

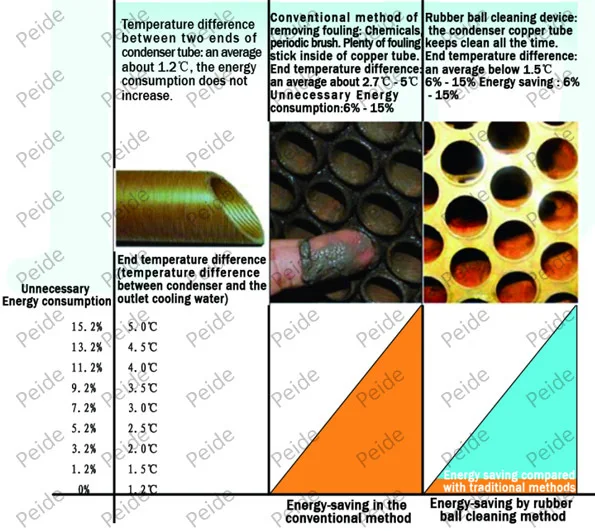

After installing central air conditioner condenser rubber ball automatic cleaning device, the condenser is running with no dirt clean state to host a 300-ton (lose the power of 200KW) under 5000 hours in the boot cases: power consumption = 200KW ×80% ×host load boot 5000 hours = 8 million degrees

Suppose 1.0 yuan / kWh tariff calculation, the corresponding cost: 8,000,000 ° ×1.0 yuan / kWh = 8,000,000 yuan

Traditional methods of decontamination 6-15% more consumption: 8 million yuan ×6% = RMB 48000 yuan

Chemical cleaning twice yearly, once by 30,000 yuan terms, a total of 60,000 yuan annual clean-up costs.

Rubber ball cleaning device installed annual cost savings: 48,000 yuan yuan = 108,000 yuan +60000

3000 hours only be able to run equipment to recover the investment, according to a 10-year period, the cost savings of 108,000 yuan ×10 years = 1.08 million yuan

•saving on the cost of chemical cleaning of the condenser produced each year, reducing the management of the central air-conditioning system maintenance costs.

•Avoid the condenser wall by chemical and microbial membranes corrosion, extending the life of the air conditioning system.

•You can get financial incentives for energy-saving or financial subsidies from the relevant government departments.

•For local government departments concerned, promote the use of technology can help complete PD energy reduction targets, more to protect the environment, reduce waste, construction section

About society and the interests of future generations to benefit society.

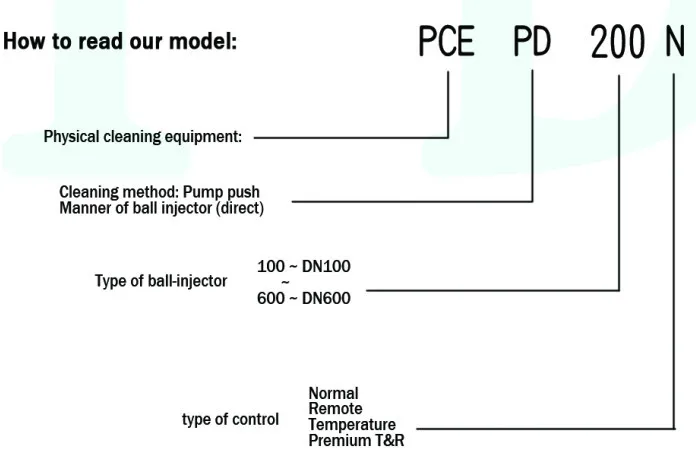

Online condenser rubber ball cleaning device design and selection

1. Chiller water treatment circulating cooling water system meets the national standard "industrial cooling water treatment design specifications" GB50050-2007's request.

2. Online condenser rubber ball cleaning device design and selection is based on the chiller cooling capacity and the cooling water outlet pipe diameter, based on the size of the plastic ball chiller condenser tubes inside diameter.

Injector:it is AC input power 3 ×380v / 50HZ, power between 1.5KW-5.5KW, Japan Power consumption: <1kwh. Working temperature: 0 ℃~ + 60 ℃Humidity: 20-95%

Set aside not less than 600mm of maintenance space around.

Injector should be close to the condenser inlet.

3.Online condenser rubber ball cleaning device conditions: You can not have impurities foreign body tubes to prevent gum ball through. The water should not contain more than 1.5mm diameter

Impurities, tubes and collect the ball will cause clogging.

To avoid the cooling tower fill welding slag, welding, metal debris, sand, organic fabrics and produced during operation of the installation process, the cooling of the rust

Corrosion products and other foreign matter into the condenser and evaporator design takes the chiller condenser (evaporator) into the set before the outlet filter pore size of not more than 1.5mm

Filter, and the filter connection effective filtration area is larger than the pipe cross-sectional area more than three times, to ensure water resistance and reasonable filter.

4.About condenser (evaporator) designed and installed at the entrance to recommend P-type filters Note: Due to many reasons chiller room layout, circulation pump outlet to the inlet of the long distance, pipe, parallel pipes, manifolds more chillers, installation the presence of welding slag, welding leavened many hidden dangers, coupled with uncooled season after drainage systems, pipe wall corrosion material loss; so even though the pump is installed at the entrance of qualified filters often chiller condenser (evaporator) heat there is a large presence of foreign material inside the tube size. So in order to avoid the above happening, considering the economy, regular cleaning of the filter to facilitate foreign body, it is strongly recommended that design and install filters.

Technical parameters

1. Performance: ball collecting rate ≤95%

2. Input voltage: 380V / 50HZ

3. Power: ≤5KW

4. Work environment requirements: Temperature ≤55 ℃, humidity ≤95 ℃Relative

5. Pressure loss: 0.003MPa-0.05MPa

6. Water temperature: ≤50 ℃

7. Working Pressure: ≤1.6MPa

Size of host

Ball collector

| Model | L(MM) | W(MM) | H(MM) |

| PCE-PD-XX-N | 1300 | 950 | 800 |

Rubber ball cleaning device Material

Made of carbon steel or stainless steel, pressure 10-16bar, the effective flow area is greater than three times the connection pipe, fluid resistance loss is less than 5Kpa.