Brand Name: Peide Continuous Sand Filter

Model Number: HLSQ-T Continuous Sand Filter

Place of Origin: Jiangsu, China (Mainland)

Remove nitrogen and phosphorus Continuous Sand Filter

Continuous sand filter is widely used in many fields,especially for drinking water,industrial process water,sewage and industrial waste water purification. It is a kind of continuous filter,combined flocculent,settling,filtering together.For tertiary filtration of reclaimed water, the gravity sand filter offers advanced treatment:efficiently remove suspended and colloidal solid, oil,iron and manganese oxide,and kill the bacterial,algae,virus in water.

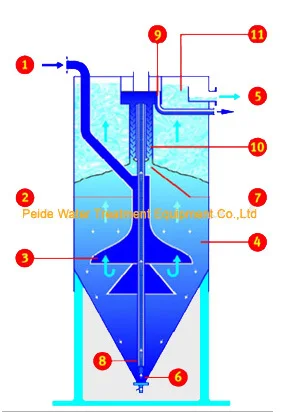

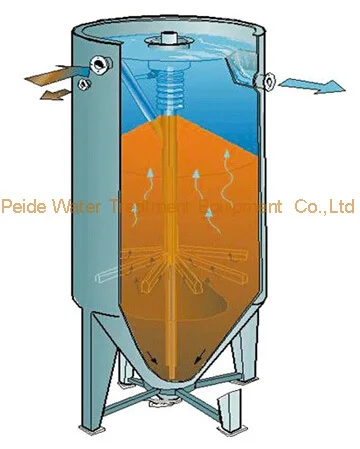

Route of water: Raw water enter into inlet pipe(1)feed into sand filter(2)and water distributor(3) into sand bed(4),

Raw water will be purified when passing through the sand bed.The filtrate flow out from(5).

Route of Sand: when the water flow upward,sand bed move downward continuously.The dirty sand was drawn from the bottom of sand bed,and begin to wash the dirty sand,return the clean sand back to the top of sand bed(7)

Route of Air: Circulation of sand is based on “gas principle”,compressed air will push the mixture of sand and water into the center pipe(8),and move upward.Suspended solid and sand separated by strong friction.Reject water pour out (9).Sand falling down in sand washer,amount of sand in air lifting pipe is decided by the amount of compressed air.

Sand Washer: The washer(10)with its well-designed hydraulic features is positioned around the airlift pipeline.

The sand particles fall through the washer,where they are finally washed by a small amount of clean filtrate,flowing through the washer counter currently.The filtrate flow is generated by a difference in discharge level between the filtrate(11) and the wash water(9)

Control way; Manual.

Open inlet valve, operate pump. Start air compressor air lift till water flow out from outlet port. When filter stop operation, turn off air lift, close inlet valve, shut pump.

1.High Efficiency: Work online 24 hours,no need stop to backwash

2.Low operating cost:No need the high flow and high lift backwash pump,and it can be programmed to control intermittent wash sand control mode, greatly reducing operating costs.

3.Low maintenance cost: without any moving parts, low failure rate during operation and low maintenance costs.

4.Low one-time investment: no coagulation tank, clarify pool and other facilities, filters, high utilization

5.Lower requirements on inlet water quality: long time bear

6.SS: 150mg / L.

7.Can withstand short time SS:250mg / L.

8.Low Head Loss: Due to the single-stage filter,we clean the sand timely, head loss will be reduced to 0.5m

9.Efficient Filtration, Stable outlet water quality: Due to the timely clean filter can ensure stable and efficient filtration, no water quality cyclical fluctuations.

10.Easy for expansion: Unit operating mode can be adjusted according to changes in water quality and quantity of filters, easy to renovate and expansion of existing facilities.

Table of Continuous Sand Filter