Brand Name: JKTL

Model Number: Y-strainer

Place of Origin: Hebei, China (Mainland)

Flange connection stainless steel y strainer

| Parts List and Standard Materials | ||||||

| Body | Cover | Screen1 | Plug2 | Gasket1 | Bolt/Stud2 | Nut2 |

| A126-B | A126-B | 304SS | A126-B | Graphite | A307-B | A563 |

Notes: 1. Recommended spares.

2. Materials of equivalent strength may be substituted at manufacturer’s option.

| Upper Pressure Limits(Non-Shock) | |||

| Size | Body Material | M.A.W.P. PSIG(Bars) | Ends |

| up to 12" size | A126-B - Cast iron | 200(13.79) | FF |

| 14" and up | A126-B - Cast iron | 150(10.34) | FF |

| Body Material | Lower Limit °F(°C) | ||

| A126-B, A395 | -20(-28.9) | ||

Features:

1. Iron strainers are complete with Flat Face flange in accordance with ASME B16.1.

2. Strainer body meets applicable ASME Standard.

3. One piece cast body.

4. Strainer is equipped with bolted cover flange that utilize a flat gasket seal.

5. Low pressure drop.

6. Upper and lower machined seats.

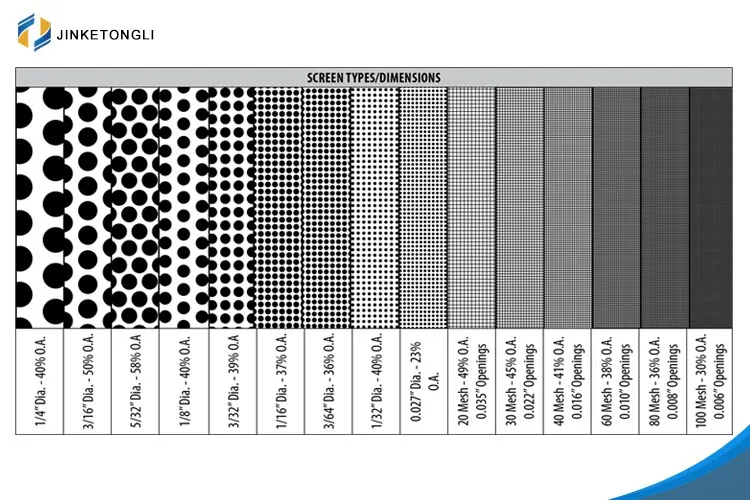

7. 304 SS perforated screens are standard.

8. Drain/blow-off connection furnished with plug as standard.

9. Generous screen area and properly proportioned straining chamber to minimize initial pressure drop

while maximizing time between cleanings.

10. Compact end to end dimension.

| Dimensional Data - Iron Class 125 | ||||||

| Size | A | B | C | D | E | Weight |

| 2" | 2 | 8.88 | 6 | 8.5 | 1/2 | 22 |

| 50 | 51 | 226 | 152 | 216 | 15 | 10 |

| 2-1/2" | 2.5 | 10.75 | 8 | 11.25 | 1 | 35 |

| 65 | 64 | 273 | 203 | 286 | 25 | 16 |

| 3" | 3 | 11.5 | 8.75 | 12.25 | 1 | 43 |

| 80 | 76 | 292 | 222 | 311 | 25 | 20 |

| 4" | 4 | 13.88 | 9.5 | 13.38 | 11/4 | 75 |

| 100 | 102 | 353 | 241 | 340 | 32 | 34 |

| 5" | 5 | 16.38 | 11.5 | 16.13 | 11/4 | 115 |

| 125 | 127 | 416 | 292 | 410 | 32 | 52 |

| 6" | 6 | 18.5 | 12.63 | 17.69 | 11/2 | 154 |

| 150 | 152 | 470 | 321 | 449 | 40 | 70 |

| 8" | 8 | 21.38 | 16.38 | 23 | 11/2 | 243 |

| 200 | 203 | 543 | 416 | 584 | 40 | 110 |

| 10" | 10 | 26 | 19 | 26.7 | 2 | 390 |

| 250 | 254 | 660 | 483 | 678 | 50 | 177 |

| 12" | 12 | 30 | 22 | 31 | 2 | 650 |

| 300 | 305 | 762 | 559 | 787 | 50 | 295 |

| 14" | 14 | 37.38 | 29 | 41 | 2 | 815 |

| 350 | 356 | 949 | 737 | 1041 | 50 | 370 |

| 16" | 16 | 42.5 | 33 | 46 | 2 | 1224 |

| 400 | 406 | 1080 | 838 | 1168 | 50 | 555 |

Purpose:

If the basket strainer is being used for protection rather than filtration, the strainer will suffice in most applications.

Service:

With services that require extremely sturdy screens, such as high pressure/temperature applications and

services with high viscosity, we recommends that perforated screens without mesh liners be used. If mesh

is required to obtain a certain level of filtration, then we recommends a trapped perf./mesh /perf. Combination.

Filtration Level:

When choosing a perf. Or a mesh/perf. Combination attention should be given to ensure overstraining doer

not occur. As a general rule the specified level of filtration should be no smaller than half the size of the

particle to be removed. If too fine a filtration is specified the pressure drop through the strainer will increase

very rapidly, possibly causing damage to the basket.

We use high quality plywood wooden case packing which avoid fumigation. It have good cushioning

performance, high strength, and corrosion resistance. The use of foam film cover the valve better to protect the valve body and fixing wooden cases is the final step.

1. Inner packing: opp bag, then carton box for each product.

2. Outer packing: export standard carton, Foam outside protecting the goods against damage.

3. Usually we ship your order by sea or by air.

4. We do our best to ship your order within 1 week after receiving your payment.

5. We'll tell you the tracking number once your order has been sent.

6. We accept T/T Bank transfer, L/C, Western Union, Moneygram, Paypal.

1. Our products have ten years warranty.

2. We have certification of ISO, and according to the rules of ANSI, we can get the ANSI certification.

3. Please feel free to call us if you have any query about the product. Professional answers will be

given to you in any time!

4. Any products you want will come to you! If you have any request, satisfying answer will reach

you from our professional team and research staff ASAP.

5. All the products can be customized!

Hebei Tongli automatic control valve manufacturing Co., Ltd. which was founded in 1995. The

company is a professional manufacturer engaged in the research, production, and sales, through

development and innovation for 20 years, research, production and sales of professional committed to the heating valve.

The company covers an area of 58000 square meters, 510 employees including 280 engineering

and technical personnel. The marketing team of 180 sales of the elite 90 people, the company has

international advancedtesting equipment 30 sets, 400 sets of CNC machine tools, products structure, the heating valve products as the leading factor, provides a full range of HVAC system design and installation, debugging program.

The company has passed the certification of ISO9001:2000 quality system, the two time the license

of special equipment, the people's Republic of China occupational health and safety management

system certification,environmental management system certification.