Brand Name: LYTTE, OEM, ODM

Model Number: LTLS Series

Place of Origin: Shandong, China (Mainland)

LTLS Series Water Chiller for Air Conditioning,

Water Chiller for Industrial Cooling, Water Chiller

Features of Water Chiller

1.30 sizes available ranging from 100 kW to 2000 kW cooling capacity, with heat

recovery and low temperature output;

2.Wide application as hotel, apartment, villa, factory, shopping center, office

building,school, etc.

3.Semi-hermetic screw compressor for all models. Each compressor is equipped

with a crankcase heater and a thermal overload cut-out, the screw compressor is

also complete with a built-in electronic protection with temperature sensor located

directly in the motor winding and on discharge line.

4.The refrigerant circuit is complete with sight glass, filter drier, high and low

pressure gauges, solenoid valve, direct expansion valve, high and low pressure

switch.

5.Shell and tube dry expansion type condenser, factory insulated with flexible close

cell material.

6.The electric panel consists of compressor breaker, compressor contactor, phase

sequence relay, control circuit breaker,

microprocessor control with function display.

7.LCD display, touch screen control panel as standard.

8.Automatic operation dramatically reducing maintenance cost thanks to reliable

microprocessor system.

9.For the units with semi-hermetic screw compressor, an infinitely variable capacity

control system that is capable of exactly

matching the demand requirement of the system is to be supplied. This system is to

provide precise and stable control of supply water temperamture over the complete

range of operating conditions.

OPTIONAL

Electronic expansion valve

Desuperheater as optional.

Electronic controller with BMS system.

Low noise compressor cabinet or outside full cover

Channel Steel base

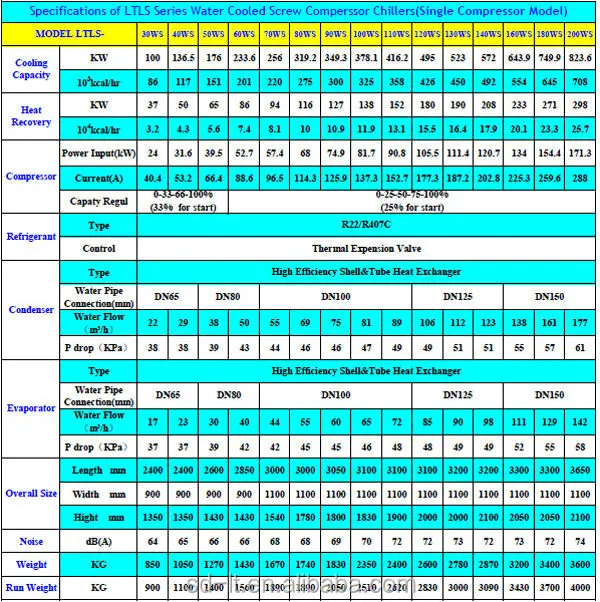

Model Specification of Water Chiller

LT L S---30 W(R) S L(G)

Notes:LT--LVTE Company Products Code

L--Screw Compressors S--Chiller, Cooling Only

30--Compressor HP

W--Water Cooled

R--With Heat Recovery

S--Single Compressor

L(G)--Chiller Water(Glycol Water) Output Temperature;

L:Glycol Water in/out -1°C/-5°C; G-Glycol Water in/out -11°C/-15°C;

None:Chilled Water In/out 12°C/7°C

Technical data of Water Chiller

Semi-hermetic Screw Compressors Units;

Most used for Central Air Conditioning Cooling System;

Evaporator C hilled Water Inlet/Outlet Temperature: 12°C/7°C;

Condenser Cooling Water Inlet/Outlet Temperature: 30°C/35°C;

Heat Recovery is an optional.

Single Compressor Unit Model: LTLS-30W(R)S to LTLS-200W(R)S

(Capacity 100KW-823.6KW/30Tons-250Tons)

Remark:

1.Colling Condition:Chilled water in/out 12/7°C; Cooling water in/out 30/35°C;

2 .Power supply: 3P-380V-50HZ;with voltage allowance ±10%,voltage dif between the phase lines±2%;

3 .The data above is for R22, contact us if that for R134a,R407c and other refrigerant need;

4 .There may be Changes for improvement without notice, confirm always before your order.

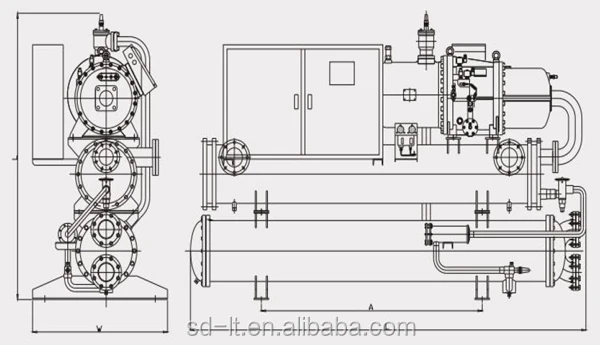

Overall Size of Single Compressor Water Chiller

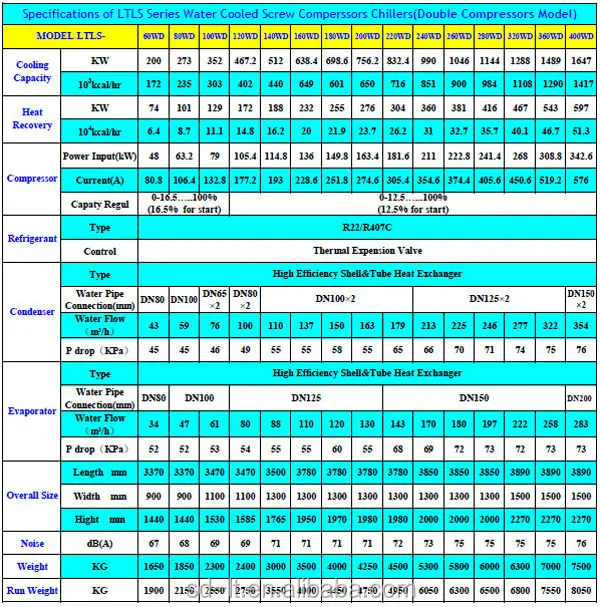

Double Compressors Unit Model: LTLS-60W(R)D to LTLS-400W(R)D

(Capacity 200KW-2000KW/60Tons-500Tons)

Remark:

1.Colling Condition:Chilled water in/out 12/7°C; Cooling water in/out 30/35°C;

2 .Power supply: 3P-380V-50HZ;with voltage allowance ±10%,voltage dif between the phase lines±2%;

3 .The data above is for R22, contact us if that for R134a,R407c and other refrigerant need;

4 .There may be Changes for improvement without notice, confirm always before your order.

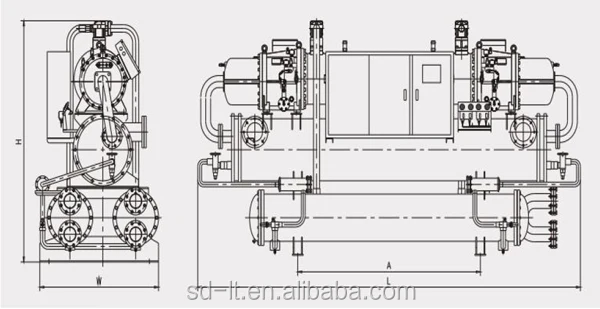

Overall Size of Double Compressor Water Chiller

Water Chiller System Control

1.Imaged system operation chart, showing the temperature of water in/out, the

energy level of compressor run, on/off button,run time, alarm etc.And the remote

turn on/off function is available. PC remote control is optional.

2.Notice for maintenance is indicated according to the accumulated run time of

the compressor.It is convenience to maintenance.

3.The control system will automatically balance the run time for each compressor for

mult-compressor unit.

Water Chiller Safety Protections

1.Discharge check value:it prevents the discharged gas from going back after the

compressor stops.

2.Phase lack protection:It protects the compressor for over high voltage, voltage

dificiency, and phase lack.

3.Direction protection:It protects the compressor from damage resulted from Counter

direction run.

4.Oil heater: It heats the oil before the unit start, keep the good lubrication for the

unit before it runs.

5.Overheat protection inside the motor of the compressor: It protects the compressor

from burning down for too high coil temperature for overload, or abnormal run condition.

6.High&low pressure protection:It protects the compressor and system against extreme

run condition and trouble.

7.Freezing protection:It protects the unit form too low temperature of the water out,

freezing may occerat some place,resulting in freezing breaking of the evaporator.

8.Water flow protect:It protects the unit from run without water flow.

9.High temperature of chilled water protection: It works to protect the compressor in

case that the load is too large,the temperature of chilled water is too high.It may result

in compressor failure without this protect in the case.The technical data in this documents

are not binding. LVTE AIR CONDITIONING SYSTEM CO.,LTD.

Finished Water Chiller Products

Single compressor

Double Compressor

Water Chiller in Warehouses

Certificates