Chemical composition:

C: ≤ 0.07, Si: ≤ 1.0,Mn: ≤ 2.0,Cr: 8.0 ~ 20.0,Ni: 8.0 ~ 11.0,S: ≤ 0.03,P: ≤ 0.035

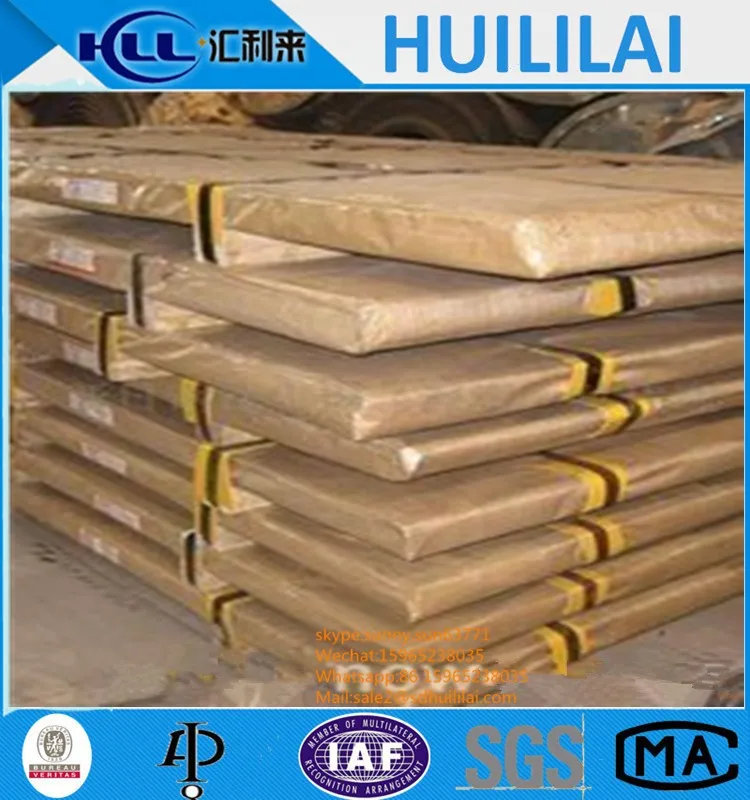

Category:

A. hot rolled steel plate B. cold rolled steel plate

Basic overview of 304 stainless steel

Method divided by two hot-rolled and cold-rolled, according to the organizational characteristics of steel divided into five categories: austenitic, austenitic - ferritic, ferritic, martensitic, precipitation hardening. Requirements withstand acid, sulfuric acid - ferric nitrate, nitric acid - hydrofluoric acid, sulfuric acid - copper sulfate, phosphoric acid, formic acid, acetic acid and other corrosive acid widely used in chemical, food, pharmaceutical, paper, petroleum, nuclear industrial, and construction, kitchen utensils, cutlery, vehicles, household appliances all kinds of parts.

Stainless steel surface finish, higher ductility, toughness and mechanical strength, acid and alkaline gases, solvents and other corrosive media. It is not easy to rust the steel, but not definitely not rust. Corrosion-resistant stainless steel alloy depends on its composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal organizational structure, play a major role is chromium.Chromium has a high chemical stability, in the passive film formed on the surface of steel, the metal with the outside world to isolate and protect steel from oxidation and increase the corrosion resistance of steel. After the destruction of the passive film, corrosion resistance on the decline.