Brand Name: YEMOO

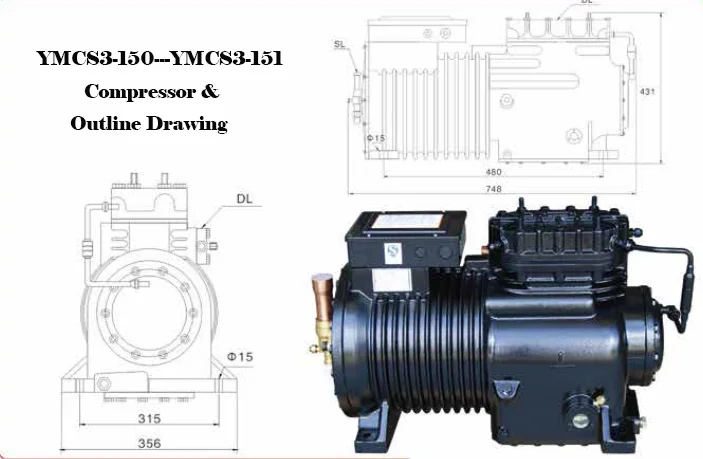

Model Number: YMCS3-150 (copeland freezer compressor)

Place of Origin: Zhejiang, China (Mainland)

1. Features:

1) Introduction

Developed technology, compact dimensions

Small volume and space

High precision machining to ensure the compressor confirm with the standard

CNC processing center

Concentricity due to specific processing technology

Minimal dead space

Steady operation, small vibration and low noise

Excellent stability

Refrigerant like R22 and R404 are adopted to protect the environment

For mid&low temperature application

Electrical motor protect device

PTC sensor

Wear resistant driver gear

Chrome plated piston rings and aluminum pistons

Hardened crank-shaft

Low friction bearing set

Efficient valve plate design, high refrigerating capacity and low energy consumption

Efficient compression rate

Valve reed made of imported impact resistant spring steel

General spare parts, convenient for maintenance

2)Wide range of application

The copeland freezer compressor uses R22 as refrigerant. R134a, R404a, R407b and R407c are also approved. R12 and R502 are not suggested due to the international environment protection requirement. The copeland freezer compressor machine can be used at a low or high condensing temperature.

3)Excellent performance

The copeland freezer compressor has a scientific structure design, strictly chosen material and precise procession and it is strictly inspected. The factory has obtained the National Compulsory Products CCC Certification, the National Industrial Products Manufacture License, and the ISO9001:2008 International Quality Supervision System Certification.

4)Reliable safety device

The copeland freezer compressor is equipped with motor protector and discharge temperature monitor to prevent the overheat of the motor and the copeland freezer compressor and the operation beyond approved application pressure.

2.Accessories of YEMOO Condensing unit:

Note: Our connecting welding rod is using Harris imported from USA. Other spare parts can based on the customer's requests.

R22 refrigerant

| Model | Condensing Temperature oC | Refrigerating Capacity QO (W) Power Consumption Pe(KW) | |||||||||||||

| Evaporating Temperature oC | |||||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | |||

| YMCS2-080 | 30 | Qo | 28140 | 22790 | 19300 | 15580 | 12320 | 9650 | 7270 | 5350 | |||||

| Pe | 5.07 | 4.91 | 4.69 | 4.42 | 4.10 | 3.75 | 3.35 | 2.95 | |||||||

| 40 | Qo | 25580 | 20930 | 16970 | 13480 | 10500 | 8250 | ||||||||

| Pe | 6.25 | 5.85 | 5.42 | 4.97 | 4.50 | 4.00 | |||||||||

| 50 | Qo | 23260 | 19180 | 14650 | 11740 | 9070 | 6740 | ||||||||

| Pe | 7.03 | 6.55 | 6.00 | 5.40 | 4.75 | 4.15 | |||||||||

| YMCS2-100 | 30 | Qo | 26510 | 21620 | 17450 | 13720 | 10700 | 8140 | |||||||

| Pe | 7.15 | 6.75 | 6.25 | 5.75 | 5.20 | 4.65 | |||||||||

| 40 | Qo | 23730 | 19420 | 15350 | 12100 | ||||||||||

| Pe | 8.20 | 7.60 | 6.90 | 6.25 | |||||||||||

| 50 | Qo | 21040 | 17090 | 13490 | 10580 | ||||||||||

| Pe | 9.15 | 8.30 | 7.50 | 6.65 | |||||||||||

| YMCS3-150 | 30 | Qo | 38960 | 31750 | 25350 | 20170 | 15700 | 11980 | |||||||

| Pe | 10.30 | 9.80 | 9.10 | 8.25 | 7.40 | 6.60 | |||||||||

| 40 | Qo | 34890 | 28260 | 22560 | 17800 | ||||||||||

| Pe | 11.80 | 10.90 | 9.90 | 8.85 | |||||||||||

| 50 | Qo | 30700 | 24880 | 19650 | 15580 | ||||||||||

| Pe | 13.10 | 11.90 | 10.75 | 9.50 | |||||||||||

| Refrigerant Gas R404A/R507A | Refrigerating Capacity Q0 (W) | ||||||||||||

| Model | Condensing Temperature oC | Evaporating Temperature oC | |||||||||||

| 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | ||

| YMCS2-080 | 30 | 31400 | 28700 | 24000 | 20000 | 16400 | 13400 | 10700 | 8500 | 6500 | 4900 | 3700 | 3700 |

| 40 | 26400 | 24100 | 20200 | 16800 | 13800 | 11300 | 9000 | 7100 | 5500 | 4200 | 3100 | 3100 | |

| YMCS2-100 | 30 | 44800 | 44200 | 35100 | 29000 | 23900 | 19400 | 15600 | 12300 | 9500 | 7200 | 5300 | 5300 |

| 40 | 38100 | 35600 | 29800 | 24600 | 20300 | 16500 | 13200 | 10500 | 8100 | 6100 | 4500 | 4500 | |

| YMCS3-150 | 30 | 69000 | 64500 | 54300 | 45200 | 37300 | 30500 | 25600 | 19600 | 15300 | 11700 | 8900 | 8900 |

| 40 | 58700 | 54800 | 46200 | 38400 | 31700 | 25900 | 21800 | 16700 | 13000 | 9900 | 7500 | 7500 | |

| Model | Motor Power (HP/KW) | Displa- cement (m³/h) | Number of Cylinder x Diameter x Stoke (mm) | Pipe Connections | Oil Charge (L) | Motor Connection (V/Ø/Hz) | Cran-kcase Heater (220V) (W) | Oil Supply Method | Weight (KG) | |

| DL Discharge Line (mm) | SL Suction Line (mm) | |||||||||

| YMCS2-030 | 3/2.2 | 12.2 | 2×φ47.6×39.2 | φ16 | Φ19.05 | 1.25 | 220-240/3/50 220-240/3/60 380-420/3/50 440-480/3/60 | 60 | Splashing Lubrication | 62 |

| YMCS2-040 | 4/3 | 14.7 | 2×φ54×37 | Φ19.05 | Φ25.4 | 1.25 | 60 | 85 | ||

| YMCS2-050 | 5/3.7 | 18.4 | 2×φ54×46 | Φ19.05 | Φ25.4 | 1.85 | 60 | 87 | ||

| YMCS2-080 | 8/5.5 | 26.6 | 2×φ64×48 | Φ25.4 | Φ31.75 | 3.5 | 120 | 133 | ||

| YMCS2-100 | 10/7.5 | 36 | 2×φ64×64 | Φ25.4 | Φ31.75 | 3.5 | 120 | 137 | ||

| YMCS3-150 | 15/10.5 | 54 | 3×φ64×64 | Φ28 | Φ38.1 | 4.8 | 180 | 172 | ||

| YMCS3-151 | 15/10.5 | 54 | 3×φ64×64 | Φ28.58 | Φ38.1 | 4.8 | 180 | 180 | ||

| YMCF4-150 | 15/10.5 | 73.7 | 4×φ70×55 | Φ28 | Φ42 | 4 | 140 | Forced Lubrication | 183 | |

| YMCF4-251 | 25/18.5 | 73.7 | 4×φ70×55 | Φ28 | Φ54 | 4.5 | 140 | 203 | ||

| YMCF4-200 | 20/15 | 84.6 | 4×φ75×55 | Φ28 | Φ54 | 4.5 | 140 | 192 | ||

| YMCF4-301 | 30/22 | 84.6 | 4×φ75×55 | Φ28 | Φ54 | 4.5 | 140 | 206 | ||

| YMCF6-250 | 25/18.5 | 110.5 | 6×φ70×55 | Φ35 | Φ54 | 4.75 | 140 | 224 | ||

| YMCF6-351 | 35/25.5 | 110.5 | 6×φ70×55 | Φ42 | Φ54 | 4.75 | 140 | 235 | ||

| YMCF6-300 | 30/22 | 126.8 | 6×φ75×55 | Φ42 | Φ54 | 4.75 | 140 | 228 | ||

| YMCF6-401 | 40/30 | 126.8 | 6×φ75×55 | Φ42 | Φ54 | 4.75 | 140 | 238 | ||

| YMCF6-400 | 40/30 | 151.6 | 6×φ82×55 | Φ42 | Φ54 | 4.75 | 140 | 239 | ||

| YMCF6-501 | 50/37 | 151.6 | 6×φ82×55 | Φ42 | Φ54 | 4.75 | 140 | 241 | ||