Brand Name: yongda

Model Number: WZP-160KW

Place of Origin: Henan, China (Mainland)

Best professional IGBT high frequency induction heating forging machine

Why choose us: the best and most professinal manufacturer ?

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996,which belongs to Henan high-tech enterprise ,was located in No.65, Liufu Village Liufu town, Shenqiu County, Henan ,China .

We have international trade department in Zhengzhou city. East to international airport (CGO), besides, high way, high speed rail, transport is very convenient.

We professionally dedicated to R & D, produce and sale high frequency, super audio frequency, medium frequency induction heating equipment: WGH ,WZP and KGPS series, CNC quenching machine tool and automatic feeder machine etc. We adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions.

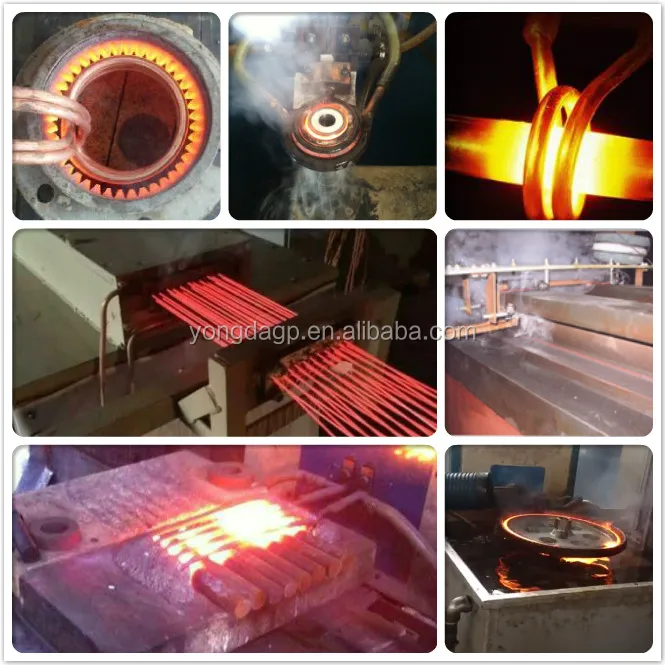

Our machine is mainly used for heating metal, induction forging, hardening, brazing, annealing, melting , shrink fit, etc. other fields.

Yongda High frequency Equipment Co.,Ltd is the leader of induction heating field and biggest full solid state induction heating equipment manufacturer in China. Our products has got CE and ISO certification and hot sale at home and abroad. Up to now, we already exported to Europe, America, and Southeast Asia etc. other regions.

Welcome everyone to visit us and negotiation business ! (We are in exhibition)

Technical paramters of 160kw high frequency induction forging heating machine

Model |

WZP-160 |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V |

Input current |

6-300A |

Input power |

10-160KW(power adjusted stepless) |

Oscillation frequency |

10-50 KHZ |

Cooling water pressure |

0.3 MPA |

Size of geneartor: Transformer |

850*600*1330mm 780*540*520mm |

Weight of generator ; transformer |

147kgs; 108kgs |

Water cooling protection point |

Below 50 degree celsius |

Description about Yongda high frequency induction heating forging machine

1. IGBT technology, Imported IGBT module, Germany Siemens technology

2. Every components are strictly tested before assembly machine

3. Professional technial staff debug machine before it leaving our factory

4. Experience designer and engineer design and make induction coils

5. Work stable and performance well

6. Fault rate is almost zero

7. One year free replacement spare parts

8. English install and operating manual, help and instruct user and our agent .

9. Other equipment matching with our induction heating machine, such as hot forging /punching machine, automatic feeding machine, CNC quenching machine tool , temperature controller , remove oxide layer etc.

10. Product hot sale in domestic and foreign county

Applications

High frequency induction forging:

(1) Round steel categories:

A. bolts, nuts, drill head hot forge, the car U-bolts, anchor bolt, connecting rod, non-standard parts processing, conductive rod

B. stainless steel tableware, stainless steel bolts and nuts

C. tools: pliers, bolt cutters, pipe clamp, water pump pliers, pliers, wrenches, ratchet wrenches, masonry chisel,

D. Other: sewing gadgets, jack head, boss chair, shackles, hand rings, flowers Lancashire body, feet kidnapper, tricycle axle, briquettes machine Chong-pin, roll gate axis, articulated manifolds, hot-rolled twist drill, Hot-rolled rebar, hot-rolled woodworking drill, bearing

(2) sheet/plate categories:

A. forged stainless steel cutlery, automotive steel plate.

B. sheet folding: folding iron hand jack, metal folding channel, automotive steel, hot rolled construction steel buckle, automotive leaf spring

C. embossed: Iron Works embossing, embossing motorcycle brake pedal heating, sanitary ware.

D. Forming: bending, upsetting head, punching, flatten, step by step tight angle iron molding, from nails, rasp, sanitary ware

(3) pipe deformation: pipe heat distortion, fire extinguishers stretching, stretching cylinders, fans rose shaped brackets bend, pipe up hole, bicycle fork shrinkage, food machinery punching

(4) other categories:

Electric Vehicle wrist, drill rod, drill bits, copper pieces (communication, air conditioning parts), trains pin, watch cases, railway rail pressure ring.

Packing for high frequency induction heating forging machine

1.Two wooden cases (plywood) ,as you request.

Inside,will be filled with plastic foam,for waterproof and shockproof.

2.Accessories: high frequency cable 2 pcs, (connect generator and transformer)induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air/train etc.

Sincerely provide service for you!