Brand Name: Yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

35kw high frequency induction heater heating/forging/brazing /hardening device

The products

The induction coils of maichine

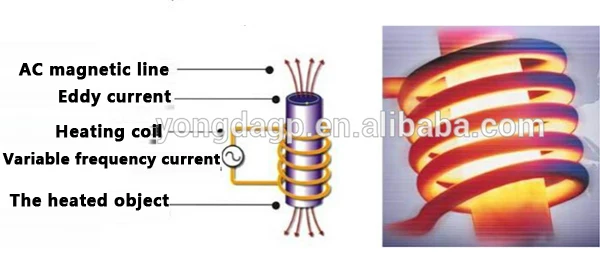

The Working principle diagram

The main technical parameters

Model |

WZP-60 |

Input voltage |

320-420V |

Input current |

2-60A |

Oscillation frequency |

15-30KHZ |

Cooling water pressure |

0.3 MPA |

Size of generator |

590*330*455mm |

Size of transformer |

500*360*455mm |

Weight of generator |

41KG |

Weight of transformer |

37KG |

The features of our factory products

1) no overall heating of the workpiece,it can be selectively localized heat, thus less power consumption, small deformation of the workpiece.

2) fast heating, enhances the processing in a very short period of time to achieve the required temperature, or even 1 second. So that the workpiece surface oxidation and decarbonization are lighter, most of the artifacts are not gas.

3) the equipment needed by adjusting the operating frequency and power, the surface hardened layer of regulation. So that the hardened layer of fine martensite, hardness, strength and toughness are high.

4) after heat treatment by induction heating of the workpiece, the surface under a thick layer of hard toughness region, with better compression stress, fatigue and the workpiece are higher breaking capacity.

5) heating equipment on the production line is easy to install, easy to implement mechanization and automation, ease of management, can effectively reduce the transport, saving manpower, increase production efficiency.

6) multi-usage. Complete quenching, annealing, tempering, normalizing, quenching and other heat treatment process, but also complete welding, melting, hot assembly, disassembly and heat through hot forming and so on.

The range of application

1, through thermoforming all kinds of standard parts, fasteners, machinery parts, hardware 1. IGBT modules, save energy than traditional high frequency tube heater.

2. Protect full.Over current.over voltage,lack of phase,water shortage, etc. more than ten alarm lamps.

3. Heating fast.Within1 second ,temperature rise up to 1200 degree,even higher.

4. No need contacting work pieces, safety, safe and reliable.

5. Environmental friendly,no pollution, good for worker's health

6. Easy to change induction coils, for heating different shape of steel billet

7. Easy to install and operate.

8. Low maintenance cost

We are in induction heating exhibition

The certification

The certification

The workshop

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to Research & Development,production of high frequency induction heating machine, medium frequency induction heating equipment,supersonic frequency induction heating machine,induction forging machine, induction hardening machine, adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004. Up to now, we has 83 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.

Company products:

Medium frequency induction heating machine IGBT and KGPS SCR

High frequency (Super audio ) induction heating machine

Induction hardening machine, induction forging machine,induction brazing machine, induction annealing furnace,

Electromagnetic induction heating equipment,Induction melting furnace ;

CNC hardening machine tool,Automatic feeding steel rods machine,

Round bar,steel pipe induction hardening and tempering equipment

Concrete pump pipe dedicated quenching machine,Hydraulic cylinder cladding equipment;

Closed cooling tower,etc.

Products applications:

Metal forging,hardening,brazing, annealing, melting,shrink fit, thermal compound,plastic machine screw cylinder heating etc. other fields.

Corporate Culture

Quality goal: Zero annual customer complaint rate

Quality policy: Scientific management, pursuing excellence, elaborate and perfect works.

Quality concept: Product quality and the future of Yongda are controlled by us.We will make every efforts let Yongda quality arrive perfection , based on strict and efficient attitude .

Service concept: Customer is in my heart. What users need, what Yongda provides.We will take real actions to solve problems for customers.

Good faith: The people who are honest will possess real friend. The enterprise that is in good faith will make long-term development.

Innovation: Innovation is the driving force for enterprise development. Without innovation there would be no rapid development for enterprises.

Sincerely welcome customers at home and abroad to visit us and negotiation business !

Address: NO.65,Liufu town economic and technical development,Shenqiu County, Zhoukou,Henan, China

Contact: Dean Guo

Mobile :0086 137 8367 0175

Tel : 0086 371 5501 6296

QQ : 3238426110

Thanks for your visit ! Welcome to cooperate with us!