Brand Name: Yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

IGBT technology induction heat treatment furnace

Technical specifications of WZP-60 induction heat treatment furnace

| Model | Work power | Output power | Oscillation frequency | Output current | Cooling water pressure | Packing Size | Weight |

| WZP-60 | three phase 380V+/-10% 50-60HZ | 3-35KW | 10-50KHZ | 3-60A | 0.1-0.2MPA | control cabinet 590*330*650mm transformer 500*360*455mm |

41kgs;37kgs |

Features of induction heat treatment furnace

A. Light weight, small size and modular design

B. IGBT inversion technology, high-efficient conversion,LC series resonance

C. Environmental protection,easy operation, low labor intensity

D. Low energy consumption, energy saving 15%-30% compared to SCR technology

E. Melting rapidly, heating evenly, no oxide layer, and using timer to make sure producing high quality product with high and good consistency

F. Perfect protecting function of over temperature, over current, over/low voltage temperature, water shortage,phase failure etc. safety and reliability

G. 100 percent success rate of start-up, power factor always over 95%

H. equipped with infrared temperature detecting system(optional)

I. equipped with water cooling system(optional)

J. equipped with CNC or PLC controlling equipment(optional)

Applications of induction heat treatment furnace

1. Brazing categories:

1.1 welding diamond saw blade, carbide saw blade welding and diamond cutting tools, grinding tools, drilling welding.

1.2 carbide cutting tools for machining welding. Such as turning, milling cutter welding.

1.3 mining tools, welding, such as "one" bits, pillar gear drill bits, dovetail coal drill bits, drill rods riveting, all kinds of shearer, a variety of shearer, boring machine pick a variety of welding.

1.4 The welding of various wood working tools, such as various woodworking planer, milling, and welding a variety of woodworking drill.

2. Forging, rolling class

2.1 The variety of hot-rolled twist drill.

2.2 standard parts, hot forging fasteners, such as high strength bolts, nuts and so on.

2.3 drill steel, tempering brazing, forging, extrusion heating.

3. Heat treatment Class

3.1 The various hardware tools, hand tools, heat treatment. Such as pliers, wrenches, screwdrivers, hammers, axes and so on.

3.2 kinds of auto parts, motorcycle accessories high-frequency quenching. Such as: crankshaft, connecting rod, piston pin, crank pin, wheel, camshaft, valves, all kinds of rocker arm, rocker shaft; transmission of various gears, spline shafts, drive axle, a variety of small axes, a variety of fork and other high-frequency quenching.

3.3 power tools on the gears, shafts and other high-frequency quenching.

3.4 a variety of hydraulic components, pneumatic components of high frequency hardening heat treatment. Such as the piston plunger, rotor pump rotor on a variety of valves for the shaft, the gear pump gear, etc. quenching.

3.5 Heat treatment of metal parts. Such as the various gears, sprockets, all kinds of shafts, spline shafts, pins and other high-frequency quenching.

3.6 Machine tool industry guide, tools swallowtail quenching treatment.

4. Other

Such as precious metals smelting. Such as melting gold, silver, etc.

Packing for induction heat treatment furnace

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

1. Reply the email within 24hours. 6 staffs work for Export Department.

2. Two of them who have experience in sales, installing and after-service more than 7 years.

3. on-site engineering service.

4. 12 months warranty.

5. Color, language and logo can be printed according to your demands.

6. Plywood cases customized for sea transport.

Quality assured ! Low cost ! Considerate service ! Shenqiu Yongda welcome you !

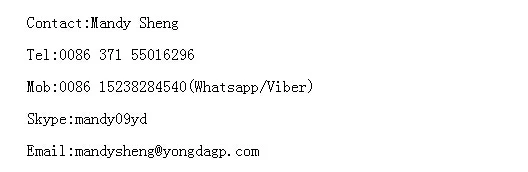

Thanks for your reading ! Welcome to contact us !