Brand Name: Yongda

Model Number: WZP-90KW

Place of Origin: Henan, China (Mainland)

IGBT imported high frequency induction heating metal hot forging machine

The HF MF induction heating machine is essentially a "converter." Its role is to converted 50KHZ AC power, into HF,MF. energy. By sensors in the high-frequency MF, energy is coupled to the work piece. Non-contact heating. Thus it is widely used. Especially heating ferromagnetic material, the effect is very good.

Advantages of induction heating machine

| 1 | Advanced Germany IGBT module,save energy 30% |

| 2 | Many components on circuit board are imported. like Integrated block is imported from Texas,USA.Small capacitancex are SIEMENS brand. |

| 3 | No need contact workpiece ,electromagnetic heating |

| 4 | Almost no oxide layer, no pollution |

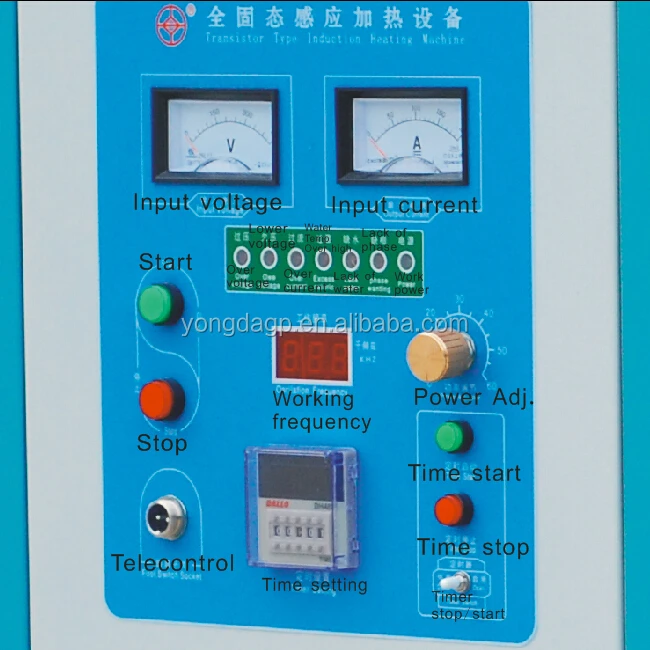

| 5 | Easy install and operate |

| 6 | Heating fast . Wide usage |

Technical parameters of induction heating machine

| Model | WZP-160 | Input voltage | 380V+/-15% |

| Input current | 6-160A | Output power | 90KW |

| Oscillation frequency | 10-50KHZ | Continuous load rate | 100% |

| Cooling water pressure | 0.3MPA | Generator dimensions (L*W*H)mm | 740*403*895 |

| Generator weight | 55kg+/-5% | Transformer dimensions (L*W*H)mm | 735*490*465 |

| Transformer weight | 74kg+/-5% | Temperature protection | below 50 degree |

Metal parts hot forging as below:

1. Plate heating, bending and forming, such as: brass, steel strenching bending, smashing head wire, heating wire nail, stainless steel and etc.

2. Standard parts, fasteners through the hot forging, such as the hardware through heat, pliers, wrenches and other heat through hot forging.

3. Real axle and hot Forging, rotor, and other parts of the thermal loading.

Packing for induction heating machine

1.Wooden cases (plywood), as you required.

2.Inside,will be filled with plastic foam,for waterproof and shockproof.

3.Accessories: induction coils,foot switch and installing and operating instructions

4. Shipping marks will be printed and pasted on the woodne cases outside.

Shipping: by sea LCL(less than container load) or by air/train/courier

Delivery time: |

3-5 days delvery goods to shanghai port |

Payment terms: |

T/T 30% advance payment, 70% before sending goods from factory,after buyer receive packing photo from seller |

Warranty: |

12 months free replacement spare parts |

After sale service: |

Provide long terms technical support |

No. Of Packages: |

Two wooden cases. |

Gross weight: |

170+/-5%kgs ,generator 80kg, transformer 90 |

Total volume: |

0.8 CBM |

HS CODE |

8514400090 |

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in No.65, Liufu Town, Shenqiu 466300, Henan, China. We professionally dedicated to Research & Development,production of

Main products:

Induction heating machine( high frequency ,medium frequency ,supersonic frequency )

Related matching equipment: CNC hardening machine tool, automatic feeding machine, closed cooling tower, industrial chiller,temperature controller

Adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004, CE certifications in 2015. Up to now, we has 36 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in Zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.

YONGDA Brand induction heating machine adopts IGBT module (Germany Siemens technology),small size, light weight, fast heating, energy saving. These advantages , won the lover from majority of users. Over the past decade, with the development of our company in high-frequency induction heating technology, applications expand, users are increasingly , our products gradually formed a relatively complete three series (WGH series, WZP series,WPS series)

1.WGH series frequency is 10-80KHZ,

2.WZP series operating frequency is 10KHZ-50KHZ.

3.WPS series apply to heating copper,aluminum,stainless steel etc, weak magnetic material heated.. working frequency 30-50KHZ,

4.MF series operating frequency 0.5-10KHZ ,

5.We also can customized double frequency machine (0.5-45KHZ )

high frequency 10-45KHZ and medium frequency 0.5-10KHZ

Products applications:

Metal forging,hardening,brazing, annealing, melting,shrink fit, thermal compound,plastic machine screw cylinder heating etc. other fields.

Thanks for your reading, welcome to contact Jessie at any time !