Brand Name: Yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

35KVA Unit-one Style High Frequency Induction Heating/Brazing/Welding Machine for brazing hard alloy

Features of high frequency induction heating brazing welding machine

First, the application of heating equipment

1, through thermoforming all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist drill of hot forging, hot rolling, metal annealing. Such as: tensile steel; wire, nail wire heating; stainless steel annealed, rose type.

2, heat treatment various types of hardware tools, electric, hydraulic, pneumatic components, automotive, motorcycle parts and other mechanical parts of the surface of the metal, the hole, partial or total quenching. Such as: hammer, knife, scissors, pliers and all kinds of shafts, cams, sprockets, gears, valves, ball stud, a large machine tool guide, ductile iron quenching.

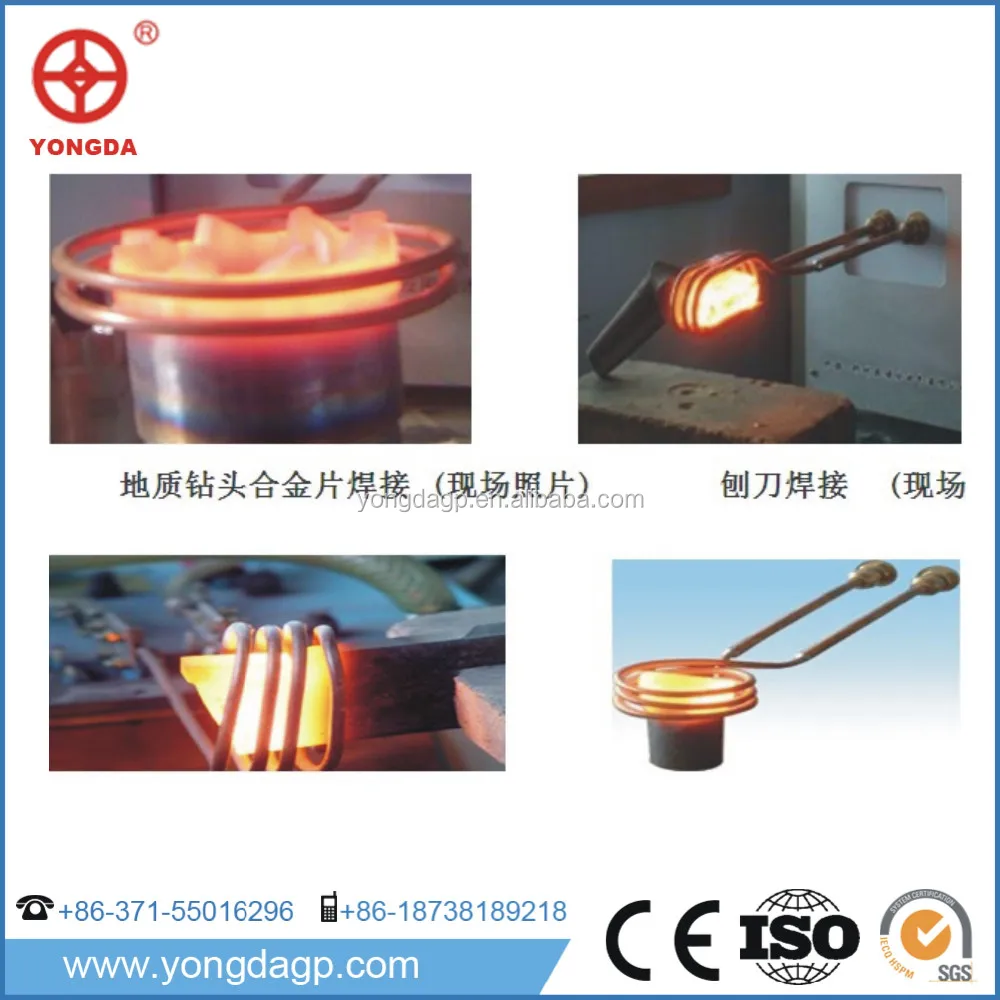

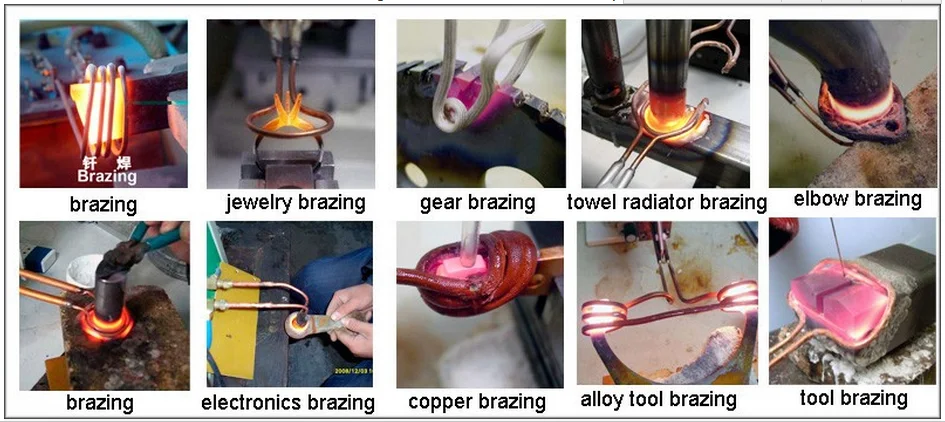

3, various types of brazing carbide blade, turning, milling, planing, reamer, diamond saw blade, serrated welding; grinding, drilling, cutting welding; brass, copper, stainless steel pot, etc. hybrid welding of metallic materials.

4, metal melting: melting gold, silver and copper.

5, other areas of plastic pipe heating cable, heating wire coating; food, beverage, pharmaceutical industry, the use of aluminum foil.

Second, product features:

1, small size, light weight, easy installation, easy operation.

2, high efficiency, saving energy obviously, high-frequency energy-saving equipment than the traditional 60%

3, safe and reliable, no million-volt high-pressure, very safe for the operator.

4, the frequency bandwidth to meet the different parts of brazing, heat treatment, forging before heating.

5, a unique cooling system, ensure that the equipment 24 hours of continuous work.

Main technical parameters of WZP-35 high frequency induction heating/brazing/welding machine

Model |

WZP-35KW |

Work power: |

3 phase 380V+/-10%, 50-60HZ |

Input voltage: |

320V-420V |

Input current: |

3-60A |

Output power: |

3-35KW |

Oscillation frequency: |

30-100khz |

Cooling water pressure |

0.1 MPA |

Size of generator: |

590*330*650mm |

Size of transformer |

500*360*455mm |

Weight of generator |

41kgs |

Weight of transformer |

37kgs |

Applications of high frequency heating brazing/welding machine

1. Welding saw blades,turning tool,reamer,the impact of drilling,thin drill bit,pick,coal bit,welding of stainless steel products,small metal 2. work parts heat treatment Tools, reamers, cutting tools, drill bits, drill bits, cutter, woodworking tools, garden tools, stainless steel products, steel, yellow copper parts welding

3. Diathermy forging , slideway, gear, sprocket,axis quenching, fasteners heat forge, hot rolled twist drill.

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-40 |

320-420V |

2-40A |

10-50KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

10-50KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

10-50KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

10-50KHZ |

0.3MPA |

WZP-160 |

320-420V |

6-160A |

10-50KHZ |

0.3MPA |

WZP-200 |

320-420V |

6-200A |

10-50KHZ |

0.3MPA |

WZP-300 |

320-420V |

6-300A |

10-50KHZ |

0.3MPA |

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

High frequency induction heating / forging

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to Research & Development,production of high frequency induction heating machine, medium frequency induction heating equipment,supersonic frequency induction heating machine,induction forging machine, induction hardening machine, adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004. Up to now, we has 83 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.

Company products:

Medium frequency induction heating machine IGBT and KGPS SCR

High frequency (Super audio ) induction heating machine

Induction hardening machine, induction forging machine,induction brazing machine, induction annealing furnace,

Electromagnetic induction heating equipment,Induction melting furnace ;

CNC hardening machine tool,Automatic feeding steel rods machine,

Round bar,steel pipe induction hardening and tempering equipment

Concrete pump pipe dedicated quenching machine,Hydraulic cylinder cladding equipment;

Closed cooling tower,etc.