Brand Name: Yongda

Model Number: WZP-25KW

Place of Origin: Henan, China (Mainland)

High frequency induction welder heating application for pressure gauge

High frequency induction welder heating application for pressure gauge

1. Profile of Pressure gauges

Pressure gauge elbow is a fitting,which is used to connect the pressure gauge and pressure gauge measuring equipment or piping. It’s used to buffer instantaneous impact between the measured medium and spring tube of pressure gauge, at the same time, the temperature of the measured medium can be reduced. It is protecting device for the Pressure gauge

2.high frequency induction welder heating for pressure gauge

system configuration

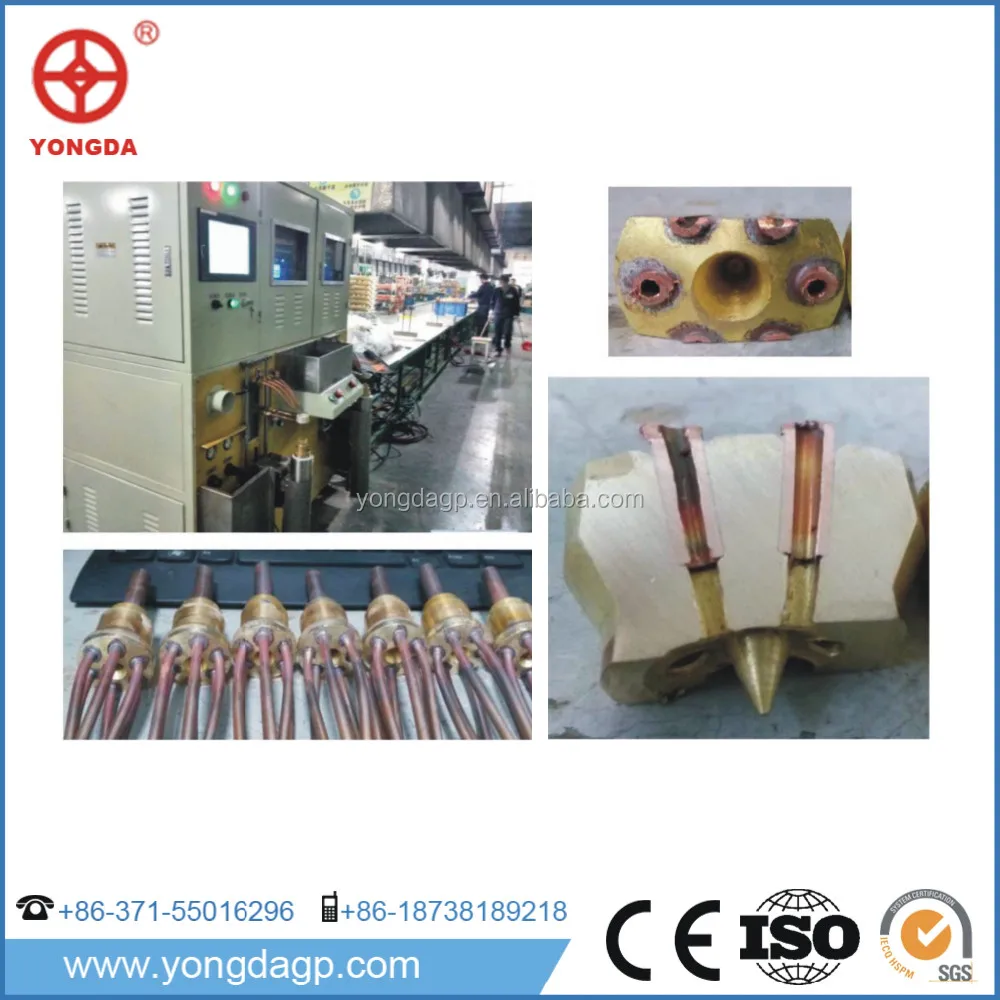

The overall framework of the entire system, including a set of double statation welding table,

2 sets high-frequency welder,

2 sets Positioning tooling,

1 set electronic control system and 1 set cooling system.

(System design according to the workpiece, will be slightly different from this figure)

Model |

Work power |

Output power |

Oscillation frequency |

Output current |

Cooling water pressure |

Size |

Weight |

WZP-25 |

three phase 320-420V/50-60HZ |

3-25KW |

30-100KHZ |

2-40A |

0.1MPA |

generator 410×290 × 500mm transformer 310×260×380mm

|

41KG,37KG |

4. Vertify conclusion-depenser

Verify project |

Manual flame brazing |

High frequency brazing |

conclusion |

One time brazing pass rate |

About 97% |

99.7% |

Pass rate higher |

Test Block pass rate |

99.6% |

100% |

No welding plugging

|

Helium inspection qualified rate

|

99.9% |

100% |

Flow into helium, no welding blocking no welding leak |

Welding seam quality |

Penetration is about 60%. |

Penetration is about 70%. |

Meet the technical requirements for quality |

Welding seam surface quality |

Solder accumulation is serious

|

dispensing head surface without serious solder accumulation |

The amount of solder reduce 3 times than manual welding |

Production efficiency |

90pcs/hour (8 hole depenser) |

50-60 pieces / person / set

|

One set machine has the same productivity with manual welding , use 2 sets, improve 30% than manual welding |

Operator |

Highly skilled welder

|

General workers operating |

Eliminate the dependence on skilled welder

|

Packing for high frequency induction welder:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

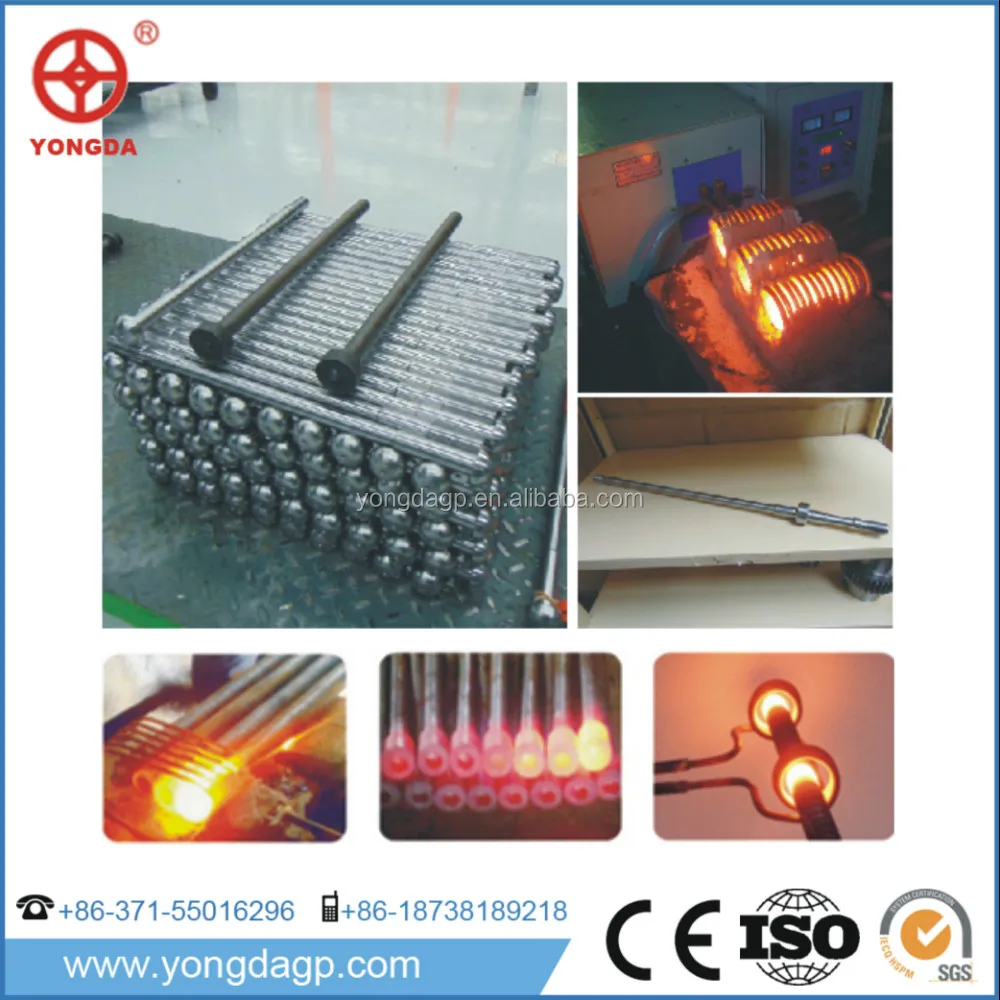

First, quenching categories:

1. All kinds of gears, sprockets, shaft quenching;

2. a variety of axle, leaf springs, fork, valve, rocker, ball stud and other auto parts quenching.

3. All kinds of engine parts, gear parts hardened surface;

4 bed machine tool of machine tool industry guide of quenching (lathe, milling machine, planer, punch, etc.).

5. All kinds of pliers, knives, scissors, axes, hammers and other hand tools quenching.

Second, Diathermy categories:

1. All kinds of bolt, nut hot forging;

2 hot-rolled cannabis cobalt;

3 diameter of 50 within all parts through hot forging;

Third, welding class:

1 piece of diamond drill bit composite welding;

2 of carbide blade, saw blade welding;

3. All kinds of cutter, drill head, drill pipe, coal drill bits, drill bits and other mine parts of the wind welding;

Successfully Case Study:

1 Shaft hardened, hardened layer of 1.5-3mm, diameter Φ10mm-250mm, bore all kinds of quenching.

2. Φ5-Φ12 wire annealing.

3 Drill head welding.

4. Φ25 bar through the following heat, the speed is much faster than the SCR. Φ60mm-Φ100mm bar diathermy

5 kinds of chains, sprockets heat treatment

6. Angang 3 meters in diameter hardened gear weight 80 tons

7. Hanjiang River Bridge with Φ1016mm thickness 17.5mm steel heated to 1,000 degrees bending shape.

8. Necking forming various types of pipe heating

9. Copper annealing, wire annealing

10. Machine Tool Gears, Sprockets quenching

11. kinds of heat flared elbow necking.

12. Φ50mm 3mm thick stainless steel annealing

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to Research & Development,production of high frequency induction heating machine, medium frequency induction heating equipment,supersonic frequency induction heating machine,induction forging machine, induction hardening machine, adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004. Up to now, we has 83 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.

Company products:

Medium frequency induction heating machine IGBT and KGPS SCR

High frequency (Super audio ) induction heating machine

Induction hardening machine, induction forging machine,induction brazing machine, induction annealing furnace,

Electromagnetic induction heating equipment,Induction melting furnace ;

CNC hardening machine tool,Automatic feeding steel rods machine,

Round bar,steel pipe induction hardening and tempering equipment

Concrete pump pipe dedicated quenching machine,Hydraulic cylinder cladding equipment;

Closed cooling tower,etc.

Products applications:

Metal forging,hardening,brazing, annealing, melting,shrink fit, thermal compound,plastic machine screw cylinder heating etc. other fields.

Address: NO.65,Liufu town economic and technical development,Shenqiu County, Zhoukou,Henan, China

High frequency induction welder,induction heating machine, Shenqiu yongda welcome your inquiry.