Brand Name: Yongda

Model Number: WZP-35KW

Place of Origin: Henan, China (Mainland)

Yongda IGBT 35KW Super audio frequency induction welding machine

Super audio frequency induction welding machine is a new type of induction heating equipment, mainly uesd in metal tube welding, alloy cutter welding, carbide saw blade welding, diamond saw blade welding, marble saw blade welding ,ect.

1.metal tube welding: such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

The advantage for use the metal tube welding(recommended silver soldering welding ring ):

(1).Induction heating speed, high efficiency.

(2).compared with oxygen welding, energy saving and low cost.

(3).oxidation of small area.

(4).the appearance is exquisite,firm,full after welding.

(5).heating uniform, so no lack solder joints and leakage solder joints.

2.alloy cutter welding:such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

The advantage for use the alloy cutter welding:

(1).Induction heating speed, high efficiency.

(2).simply put the silver solder piece between head and the substrate.

(3).energy saving and low cost.

(4).oxidation of small area.

(5).the appearance is exquisite after welding.

(6).heating uniform, so no lack solder joints and leakage solder joints.

3.carbide saw blade welding: diamond saw blade welding, marble saw blade welding,woodworking saw blade welding, cut grass piece of welding, cut aluminum welding,

The advantage for use the carbide saw blade welding:

(1).efficient and fast welding,1-5seconds per tooth.

(2).reproducibility, each tooth has a good repeatability.

(3).heat quickly and evenly, which can effectively prevent serrated local overheating caused by the jagged and brittle fracture.can also be caused by lack of penetration to prevent tooth fall off and other negative phenomenon.

(4).suitable for welding of high performance,high hardness serrated blades, this blades can not be welded with resistance welding.

(5).less electricity(2-3kw/h).

4. metal welding, such as: towel rack, soap nets, towel holder, auto-accessories, moto-accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

The advantage for use the metal welding:

(1).Induction heating speed, high efficiency.

(2).energy saving and low cost.

(3).once can weld multiple workpieces, so that can greatly increased welding efficiency.

(4).oxidation of small area.

(5).heating uniform, so no lack solder joints and leakage solder joints.

(6).the appearance is exquisite after welding.

5. small metal tin welding:

The advantage for use the small metal tin welding:

(1).Induction heating speed, high efficiency.

(2).energy saving and low cost. less electricity

(3).once can weld multiple workpieces, so that can greatly increased welding efficiency.

(4).by heating temperature low so there’s no oxidation layer.

(5).the appearance is exquisite,firm,full after welding.

Technical parameters of WZP series IGBT 35KW induction welding machine

| Model | WZP-60 | WZP-120 | WZP-160 | WZP-200 | WZP-300 |

| Worker power | Three phase 380V/50-60Hz | Three phase 380V/50-60Hz | Three phase 380V/50-60Hz | Three phase 380V/50-60Hz | Three phase 380V/50-60Hz |

| Input voltage | 320-420V | 320-420V | 320-420V | 320-420V | 320-420V |

| Input current | 3-60A | 6-120A | 6-160A | 6-200A | 6-300A |

| Output power | 35KW | 65KW | 80KW | 120KW | 160KW |

| Oscillation frequency | 15-30KHz | 10-35KHz | 10-50KHz | 10-50KHz | 15-30KHz |

| Efficiency | 100% | 100% | 100% | 100% | 100% |

| Continuous load rate | 100% | 100% | 100% | 100% | 100% |

| Cooling water pressure | 0.1-0.3mpa | 0.1-0.3mpa | 0.1-0.3mpa | 0.1-0.3mpa | 0.1-0.3mpa |

| Generator weight | 41kg±5% | 65kg±5% | 83kg±5% | 181kg±5% | 173kg±5% |

| Transformer weight | 37kg±5% | 70kg±5% | 80kg±5% | 143kg±5% | 205kg±5% |

| Generator dimensions (L*W*H)mm | 590*330*650 | 660*400*790 | 800*490*1100 | 980*720*1560 | 820*700*1700 |

| Transformer dimensions (L*W*H)mm | 500*360*455 | 600*400*380 | 860*580*730 | 910*620*820 | 1100*590*590 |

| Temperature protection | 50 ºC | 50 ºC | 50 ºC | 50 ºC | 50 ºC |

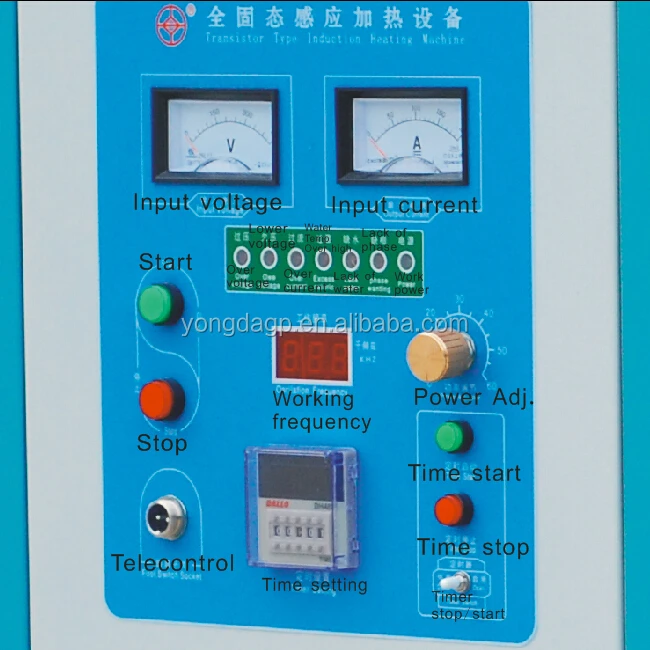

Control panel:multi-functions ,complete protecting itself. The machine has over voltage,over current,temperature is over high,lack of water, lack of phase,etc, alarm lamps indicators. can automaticly control and protection the machine itself.

Main Features of IGBT 35KW induction welding machine

1. Self-design ,Self-producing and Self-selling ensuring production quality and improving

2. High performance IGBT components than SCR/KGPS ones

3. 24 hours continuous work, 100% start-up , high power factor>0.95,easy to operate

4. Series Resonant Circuit Energy saving 15%-30% than Parallel Resonant Circuit

5. High efficiency heating attributed to Less oxide layer

6. Low consumption and Less pollution than traditional coal, gas, etc. heating

7. Suitable Model oriented to the work-piece size and production requirements

8. Good pure water cooling system