Wood flame retardant wood/timber preservation wood dyeing autoclave

Description of the wood autoclave company

Shandong zhongtaida Industrial Machinery Co., Ltd is specialized in manufacture wood preservation autoclave, wood dyeing/staining , wood cooking autoclave, vacuum high pressure wood autoclave, wood sterilization autoclave, wood oil immersion autoclave, train sleeper autoclave, bamboo and wood products carbonization autoclave, and the wood treatment line system. The autoclave for wood we design adopt vacuum and add the liquid with vacuum and pressure for a period and then draining the liquid with the pressure, open the door and take out the wood in the end.it is fully automatic in whole process.

Application scope

Vacuum pressure wood preservative impregnation treatment autoclave is a wood preservative, coloring key equipment; Wood in the tank through the pharmaceutical infusion, pressure infiltration, vacuum drying and other processes, can effectively prevent the wood rot fungi and other bacteria caused by mildew corrosion; Can effectively prevent the destruction of wood by insects such as termites, wood drilling insects and other animals. Add different agentia at the same time play a flame retardant and coloring effect. Greatly improving the service life of wood and its application. Anticorrosive, flame retardant wood is widely used in indoor furniture, wood, antique garden construction, railways, mines, dock protection wood, pile of timber construction and other occasions.

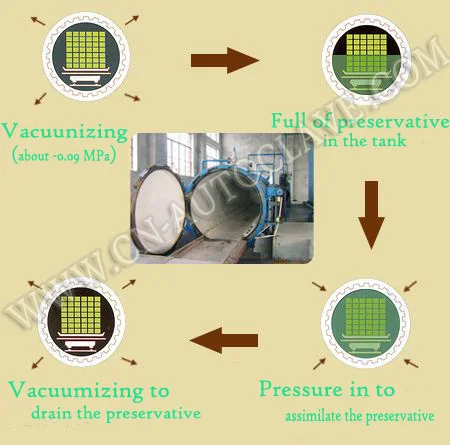

Working Principle Drawing

The characteristic of the wood treated by the pressure anti-corrosion impregnation autoclave

1. natural, environmental protection, safe(Wood into the original color, slightly green)

2. Anti-corrosion wood fire anti-corrosion, mildew, moth, anti-termite invasion

3. Antiseptic wood impregnation depth of 5-30mm, corrosion life of 20-50 years.

4. Improve wood stability, anti-corrosion wood on the protection of outdoor wooden structure is more important

5. Antiseptic wood is easy to paint and color, according to design requirements, to achieve the magnificent effect

6. Can meet a variety of design requirements, easy to a variety of gardening landscape fine wood production.

7. Antiseptic wood contact with moist soil or hydrophilic effect is particularly significant, to meet the outdoor climate environment using 20 to 50 years of the same effect.

Operating procedures

Add the timber to the vacuum pressure autoclave → close the door → vacuumize (about -0.09MPa) →injection of pharmaceuticals →boost and hold pressure (1.0-1.4MPa) → pressure relief → drainage →vacuumize (about -0.09MPa) → drying → out of the autoclave

Technical parameters and specifications

1. Wood loading capacity:1-20 m³/circle

2. Working pressure: 1.0-1.4 MPa

3. Vacuum degree: -0.098 MPa

4. Working temperature: 0-180℃

5. Working medium: Various water-soluble wood protection treatment agent solution

Wood impregnation /wood dyeing /wood preservation flow

Technical parameter

Those wood autoclave in the chart are standard configurations.

We also can customize the retort machine compliance with your specific requirements or your drawing.

Grouped equipment of the wood autoclave

The accessories of the wood impregnation autoclave

Our workshop

The insulation flow of the autoclave

Wood autoclave flaw detection

Wood autoclave water pressure test

Customer visiting view

Delivery:

We will deliver your goods by LCL/20'FCL/40'FCL depending on your order.

Before delivery, our professional technician will do trial run for each product to check until everything is functional, you also can come to our factory and test our machine together with us.

When loading, our workers will fix the retorts tightly with wire rope so that the retorts can't move in the container.

If you are interested in our products want to consult us, you can freely call us or send us Email at any time, we will be very glad to serve you. Welcome to visit our factory in Zhucheng City of China.