Brand Name: Dunan brand

Model Number: WE Series

Place of Origin: Zhejiang, China (Mainland)

Change to all-aluminium and brazed design releases the full potential of aluminium.

Design Characteristics

With an identical front surface on the airside, the micro-channel heat exchanger provides up to 10 percent added efficiency compared to a conventional fin and tube design. A lower thickness gives up to 50 percent lower pressure drop on the air side. This creates potential for lower energy consumption of the fan or, if desired, increased airflow. (Sensitivity to fouling can be expected to be lower.)

On the refrigerant side, the lower internal volume in the heat exchanger decreases the refrigerant charge.

Savings from index 100:

• 30 on required space

• 40 on heat exchanger weight

• 30 on the cost (visit the comparison table)

Unlike conventional coils, the micro-channel heat exchanger is made entirely of aluminium. This one-metal concept eliminates galvanic currents that are generated when different metals touch in conventional coils. Many comparative tests, including the salt mist and ammonium sulphate test, provide proof of the increased corrosion resistance of the all-aluminium micro-channel heat exchanger. Micro-channel heat exchangers offer three-and-a-half times higher corrosion resistance than traditional copper/ aluminium coils.

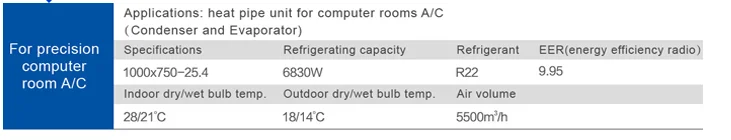

| Product specifications: |

1.We are a professional factory of copper fitting.Have exported to many countries and get good reputation with our high quality.

2.Accept OEM service,we can according to customer's drawing design.

3.More than 10 years experienced technical staff,make sure supply high quality products.

Question1: Did you accept products customization?Is they need mould fee?

Answer: Yes, we accept products customization.Need mould fee,because products usually need extra mould cost.But,we can return the mould fee when you reach a specific quantity.

Question2: Can we get free samples?

Answer: Little quantity normal copper fitting samples can provide for free except for delivery cost.

Question3: How long is the normal production period for a 20-foot shipping container?

Answer: According to the current productive capacity, usually needs 30 days from producing to delivery.

Question4:What is the type of payment?

Answer: Usually you should prepay 30% of the total amount. The balance should be pay off before we get the original B/L.

Question5:How to guarantee the high quality?

Answer: We have testing department to make sure every product of size,appearance and pressure test are good.

Question6: How is the raw copper material price?

Answer: The price of copper is decided by the LME cash buyer price at the day when clients submit the orders.