Brand Name: Peide Sewage filter

Model Number: FLQ Sewage filter

Place of Origin: Jiangsu, China (Mainland)

Automatic sewage filter brushes water treatment equipment price

Sewage filter Function and Application

Automatic backwash filter is widely used in a variety of water systems, process water systems and industrial cooling water systems, especially in online 24 hours system. It can remove all kinds of mechanical impurities in water, ensure safe and reliable operation of system. Our filter is the ideal alternative products, the indicators can reach the same level of imported filters.

Sewage filter Structure and Working Principle

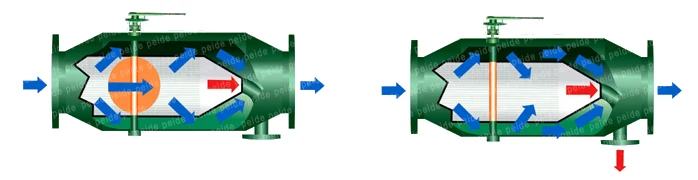

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen, flow direction valve and sewage drain. In the working status, flow direction valve is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, flow direction valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime. Flow direction valve opening mechanism include sub-manual and electric type, when using an electric opening mechanism with clock control electrical control box, it can set the time required to achieve automatic cleaning sewage, then the outfall installed electric ball valves, flow direction valve and sewage electric valve to achieve linkage.

Figure1 Normal status(flow direction valve open) Figure2 Backwash status(flow direction valve closed)

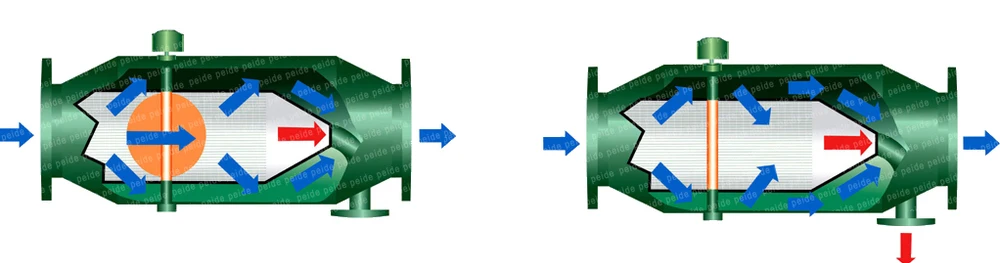

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen,electric actuator and sewage drain. In the working status,electric actuator is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, butterfly valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime.

Figure1 Normal status(flow direction valve open) Figure2 Backwash status(flow direction valve closed)

Sewage filter Features:

1.Small volume, low cost, no filter, a small amount of maintenance. Long mesh tube network life and high reliability.

2.High degree of automation, easy operation and management, long-term unattended operation.

3. Low pressure loss, energy saving, the use of the main channel hydraulic backwash, no need for backwash water.

4. Filtration precision: 1000-5000μm.

5. Easy to install, can be installed directly on the pipe, particularly suitable for field use under various process conditions.

6. Widely usage, ensure a safe operation of the water utility, simple and reliable method in any backwash process, can maintain uninterrupted normal operation.

Sewage filter Applications:

1. The domestic water supply, water supply and pre-filtering for industrial water supply;

2. steel, petroleum, chemical, paper, automotive, food, metallurgy and other industries beginning circulating water filtration;

3. Fist stage of circulating cooling water filtration;

4. The water reuse, waste water treatment filter;

5. Central air conditioning, boiler return early filter;

6. Municipal, green spraying, irrigation, agricultural irrigation, drip irrigation water filter early.

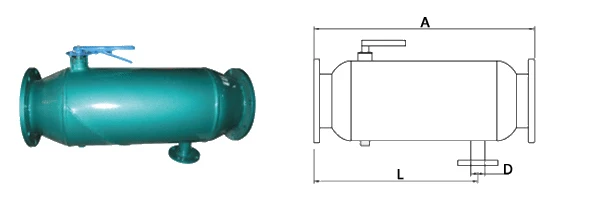

Sewage filter Models Manual type

P-type backwash filter installation diagram

| Model | Inlet&outlet | A | L | d | Flow rate | |

| inch | mm | mm | mm | mm | T/H | |

| FLQ-2P | 2 | 50 | 410 | 340 | 25 | 19 |

| FLQ-3P | 3 | 80 | 500 | 400 | 25 | 50 |

| FLQ-4P | 4 | 100 | 580 | 470 | 40 | 80 |

| FLQ-5P | 5 | 125 | 640 | 530 | 40 | 125 |

| FLQ-6P | 6 | 150 | 730 | 610 | 50 | 180 |

| FLQ-8P | 8 | 200 | 900 | 750 | 50 | 320 |

| FLQ-10P | 10 | 250 | 1059 | 900 | 50 | 490 |

| FLQ12P | 12 | 300 | 1300 | 1100 | 65 | 710 |

| FLQ-14P | 14 | 350 | 1450 | 1250 | 65 | 970 |

| FLQ-16P | 16 | 400 | 1600 | 1350 | 65 | 1260 |

| FLQ-18P | 18 | 450 | 1800 | 1500 | 100 | 1590 |

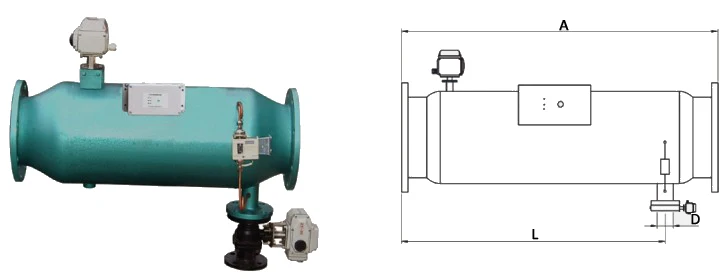

Sewage filter Automatic type

| Model | Inlet& outlet | A | L | D | Flow rate | |

| inch | mm | mm | mm | mm | T/H | |

| FLQ-2PZ | 2 | 50 | 600 | 340 | 25 | 19 |

| FLQ-3PZ | 3 | 80 | 600 | 400 | 25 | 50 |

| FLQ-4PZ | 4 | 100 | 680 | 470 | 40 | 80 |

| FLQ-5PZ | 5 | 125 | 680 | 530 | 40 | 125 |

| FLQ-6PZ | 6 | 150 | 50 | 610 | 50 | 180 |

| FLQ-8PZ | 8 | 200 | 900 | 750 | 50 | 320 |

| FLQ-10PZ | 10 | 250 | 1050 | 900 | 50 | 490 |

| FLQ-12PZ | 12 | 300 | 1300 | 1100 | 65 | 710 |

| FLQ-14PZ | 14 | 350 | 1450 | 1250 | 65 | 970 |

| FLQ-16PZ | 16 | 400 | 1600 | 1350 | 65 | 1260 |

| FLQ-18PZ | 18 | 450 | 1800 | 1500 | 100 | 1590 |

Sewage filter Parameter

| Single flow rate | 20-1000m3/h(88-4400GPM) |

| The least working pressure | ≤2.5bar |

| The highest working pressure | ≤10bar |

| The pressure loss of cleaning | ≤0.15bar |

| The highest temperature of working |

≤150℃=302°F

|

| The water consumption of self-cleaning one time | 1%-2% of all water flow |

| Filter precision | ≥1.2mm |

| Cleaning method | Brushwash |

| Cleaning Time | 30-90 seconds |

| Connect Method | flange |

| Drain Diameter | 25-100mm |

| Installation lamp | Have |

| Chamber treated method | Coslettizing |

| Working pressure | 0.6 MPa,1.0 MPa,1.6 MPa,2.5 MPa |

| Filter precision | 0.8-5mm(or customized) |

Electric

| Voltage | 220V,50Hz |

| Power | 100W |

| Control panel chamber material | Carbon steel,304ss or 316L |

| Control type | PLC |

Equipment material

| Chamber material | Carbon steel,304SS or 316L |

| Strainer material | 304SS or 316L |

| Strainer type | Stainless steel complex strainer |

| Cleaning system | Butterfly valve |

| Drain valve | Automatic drain valve |

| Seal ring | O-ring or washer |

Sewage filter Pressure Loss Table

Pipe diameter

Installation Diagram

Sewage filter Installation Precautions

1. The principle of selection:according to the pipe diameter, the premise of meeting the working pressure and flow, try to use a larger standard models.