Brand Name: G&X

Model Number: GXH

Place of Origin: Jiangsu, China (Mainland)

IGBT 30kw Induction Heater for Cutting Teeth Welding

Frequency conversion electromagnetic induction heating or induction heating for short is a method for heating metal materials by converting power frequency power supply into that of specific range based on the principle of electromagnetic induction.

Product Decription

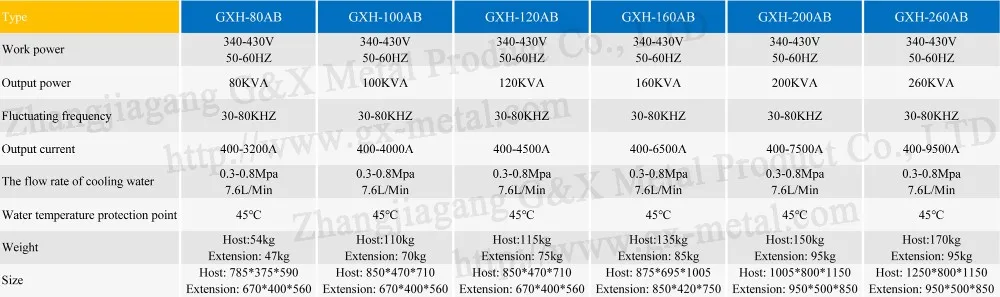

1. Technical specifications

2. Main characteristics:

1. IGBT module and inverting technologies, better performance ,higher reliability and lower

main tenance cost;

2. 100% duty cycle, continuous working is allowed at maximum power output;

3. constant current or constant power status can be selected accordingly to achieve higher

heating efficiency;

4. display of heating power and heating current and oscillating frequency;

5. multi-display functions, with displays of over current, over voltage, water failure, phase failure and unfit

lad and so on, machine can be protected from destroys and machines can be repaired easily.

6. simple to install, installation can be donned by unprofessional person very easily, connection

water and power

can be finished in a few minutes.

7. light weight, small size.

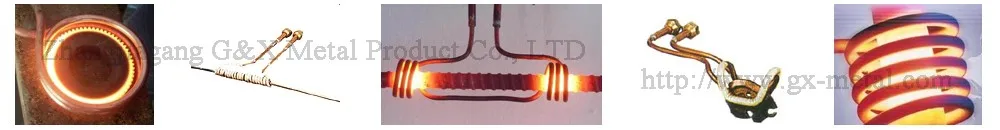

8. different shape and size of induction coil can be changed easily to heat different parts.

9. advantages of the model with timer: the power and the operating time of the heating period

and retain period can be preset respectively, to realize a simple heating curve, this model is

suggested to use for batch production to improve the repeatability.

10. the separated models are designed to fit the dirty surroundings, the generator can be put in

a clean space to increase the reliability; with the small size and light weight of the separated

transformer, it is convenient to use in the production line and easily assembled inside the

machinery or moved mechanism.

3. Product advantage

1) Fast heating

2) Wide converage of heating

3) Easy installation

4) Easy operation

5) Fast start-up

6) Low power consumption

7) High effectiveness

8) Comprehens iveprotection

9) Controllable temperature

10) Comprehensive full load design

11) Small size and light weight

12) Elimination of high volatge

3. Application

1) Heating (hot forging, hot fitting and smelting)

2) Heat teatment (surface quench)

3) Welding (braze welding, dilver soldering and brazing)

4) Annealing (tempering and modulation)

Certificate

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Our packing and delivery