Brand Name: REOU

Model Number: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi14, CuNi19, CuNi22, CuNi30,

Place of Origin: Jiangsu, China (Mainland)

Wire resistor :

We're best professional manufacturers of resistance heating alloys in China for more than 20years, specializing in NiCr, CuNi,Pure nickel,Manganin,Karmar wire,PTC thermistor alloy wire,Stranded wire,Thermocouple wire, and compensating wire etc in type of wire/strip/bar/coil/sheet/foil/plate/ribbon.

One of wire resistor: Copper-Nickel alloy :CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi14, CuNi19, CuNi22, CuNi30, CuNi34, CuNi40, CuNi44 (constantan)

Our commitment to service is based on total customer satisfaction. We guarantee quick and efficient service and feedback of wire resistor around the world through telephone or online chat(WeChat,skype,whatsapp,yahoo ect). We ensure that we will be there whenever or wherever you need us, 24 hours a day, 365 days a year.

Internal hole of the rells:

Din 250 - N. 7 – Hole size 22 mm- weight 15 to 20 Kg

Din 200 - N. 6 – Hole size 22 mm- weight 10 to 15 Kg

Din 160 - N. 5 – Hole size 22 mm- weight 5 to 10 Kg

Din 125 - N.4 – Hole size 16 mm- weight 2 to 4 Kg

Din 100 - N. 3 – Hole size 16 mm- weight 1 to 2 Kg

Din 80 - N. 2 – Hole size 16 mm- weight 0,5 to 1,0 Kg

Wire Resistor (copper nickel alloy heating resistance wire and strip) :

copper nickel alloy heating resistance wire and strip has lower electrical resistance, good mechanical, excellent welding and anti-corrosion properties. It is used to make the key components in the thermal overload relay, low resistance thermal circuit breaker, and the electrical appliances. It is also an important material for electrical heating cable. It's similar as Kanthal's type cupronickel .

TYPE |

CuNi1 NC003 |

CuNi2 NC005 |

CuNi6 NC010 |

CuNi8 NC012 |

CuMn3 MC012 |

CuNi10 NC015 |

CuNi14 NC020 |

CuNi19 NC025 |

CuNi23 NC030 |

CuN30 NC035 |

CuNi34 NC040 |

CuNi44 NC050 |

|

Composition (%) |

Cu |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

Rest |

|

Mn |

-- |

-- |

-- |

3 |

-- |

0.3 |

0.5 |

0.5 |

1.0 |

1.0 |

1.0 |

|

|

Ni |

1 |

2 |

6 |

8 |

|

10 |

14.2 |

19 |

23 |

30 |

34 |

44 |

Max.continuous operating temperature °C |

200 |

200 |

220 |

250 |

200 |

250 |

300 |

300 |

300 |

350 |

350 |

400 |

|

Nominal value μO·m(20°C) |

0.03±10% |

0.05±10% |

0.1±10% |

0.12±10% |

0.12±10% |

0.15±10% |

0.2±5% |

0.25±5% |

0.3±5% |

0.35±5% |

0.4±5% |

0.49±5% |

|

Resistance-temperature coefficient×10- 6/°C (20-600°C) |

<100 |

<120 |

<60 |

<57 |

<38 |

<50 |

<38 |

<25 |

<16 |

<10 |

-0 |

<-6 |

|

Density at 20°C(g/cm3) |

8.9 |

8.9 |

8.9 |

8.9 |

8.8 |

8.9 |

8.9 |

8.9 |

8.9 |

8.9 |

8.9 |

8.9 |

|

Melting temperature in°C |

1085 |

1090 |

1095 |

1097 |

1050 |

1100 |

1115 |

1135 |

1150 |

1170 |

1180 |

1280 |

|

Min. tensile strength in N/mm² |

210 |

220 |

250 |

270 |

290 |

290 |

310 |

340 |

350 |

400 |

400 |

420 |

|

Elongation% |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Note: special specification can be produced as per client’s request.

Application of copper nickel alloy heating resistance wire :

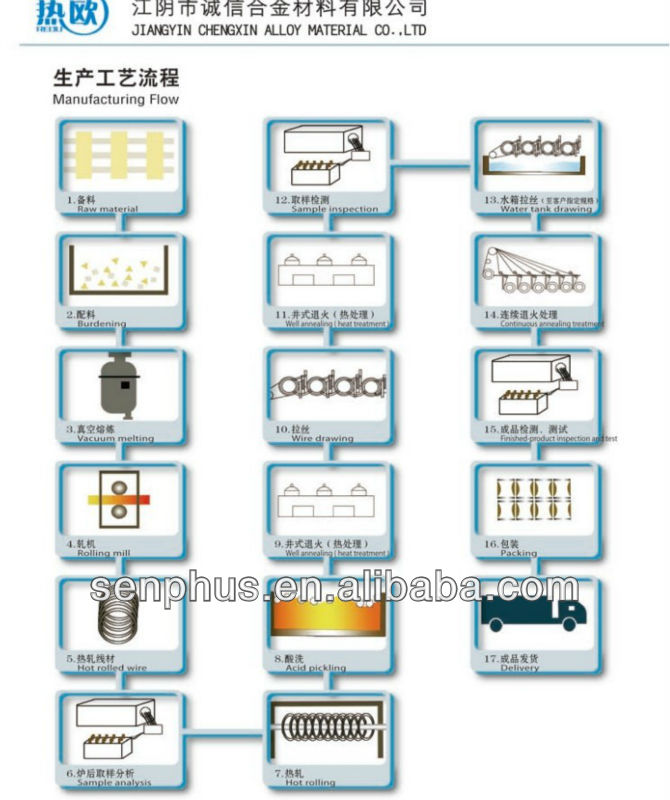

Production Process :