Brand Name: QJ 6 inch Vertical Submersible Deep Well Centrifugal Water Pump

Model Number: QJ

Place of Origin: Zhejiang, China (Mainland)

2hp Single Phase Submersible Pump

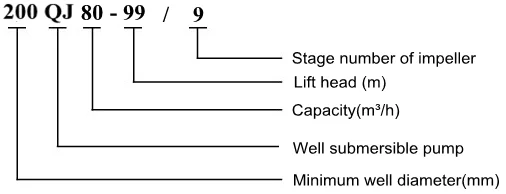

Operation Parameters: Type Explanation:

(1). Flow range : 10-500 m3/h

(2). Lift range : 10-600m

Material

| Impeller: Cast iron HT200 / Stainless Steel 304, 316 |

| Pump Bowl: Cast iron HT200 / Stainless Steel 304, 316 |

| Pump Shaft: Cold-drawn steel with chrome plating,or stainless steel SS304 SS316 |

| Motor Seal: Rubber O-ring seal,mechanical seal |

| Motor Regulating Sleeve: Rubber |

Characristics

| (1) Motors and pumps assembled into one. |

| (2) Simple structure |

| (3) Easy installation and removal, small area. |

| (4) Simple using and maintenance. |

| (5) Safe and reliable operation, no pollution to water, etc. |

Product Overview : QJ series deep

Submersible waterpumps are widely used in farm irrigation, sprinkler irrigation, getting water from well, water supply and drainage system for industrial and civil building, water diversion project in hilly and mountain areas water drainage project in at lowlying areas, water supply and drainage in urban and rural's mining enterprisesand.

various their kinds of water conservancy facilities. Its features are that the Motor and pump are assembled into a whole, so that it is simple in structure, convenient to assemble and disassemble, easy to use and maintain safe to operate. Otherwise, it covers an small area and does not pollute water.

Usages

Installation Diagram :

QJ using condition:

| (1) 380V voltage deviation is no more than ±5%,frequency is 50HZ, three-phase power deviation is no more than ±1%. |

(2) Motor cavity must be filled with water. |

| (3) The first stage impeller of the pump should be more than 2mm below the moving water surface, pump unit should be less than 70m below the static water level. |

| (4) The distance from the motor bottom to well bottom must be more than 3m. |

| (5) Water temperature should be no more than 20°C. |

| (6) Sand content of the water ( by mass) should be no more than 0.01%. |

| (7) PH value of water 6.5-8.5. |

| (8) Hydrogen sulfide content of the water should be no more than 1.5mg/L. |

| (9) Chloride ion content of the water should be no more than 400mg/L. |

| (10) Water yield of water source should ensure the requirements of pump continuous working. |