Brand Name: BEDEL

Model Number: 001

Place of Origin: Jiangsu, China (Mainland)

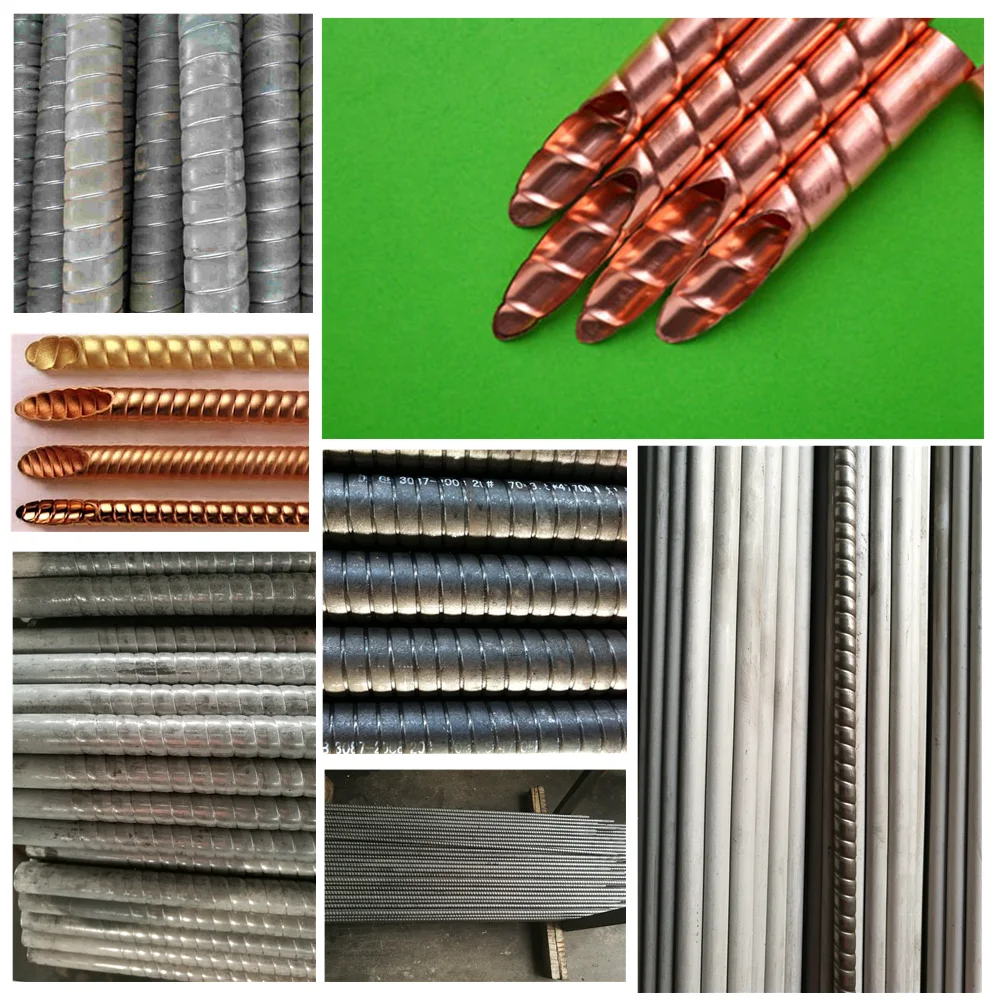

Spiral copper fin tube for rotogravure printing press machinee

Extruded Spiral Finned Tube |

Spiral Fin Tube Due to the features that higher heat transfer coefficient, larger heat transfer area and less consumption of steel etc, Threaded pipe has been recognized as a kind of strengthening heat transfer element. The research report pointed out that the design of is reasonable. So the flue gas heat transfer efficiency of threaded pipe is 1. 6 times of light tube. Because the threaded pipe has the remarkable characteristics, it has been more and more widely used in boiler manufacture. Features:

(1) The heat transfer of a thread smoke tube is as the same as that of 1.7 to 1.8 root ordinary pipes after application of the optimization of heat transfer and flow resistance when it is used on the boiler. This not only can reduce the pipe numbers, but also can lessen the diameter of the pot shell, thus, to save the steel and to cut down capital.

(2) The heat transfer surface area is 1.5 to 2.0 times of the light pipe, this greatly improves the activity of the cooling methods and strengthen the tube inside boiling and condensation transfer effects in the application of air conditioning refrigeration industry.

(3)Setting up in heat exchange equipment application on decoration, steel or stainless steel tube through a molding machine rolling, spiral tube fouling are spiraling in appearance, set decoration equipment running line temperature changes make the pipe produces expansion and contraction, thus can make the dirt to fall off; For the cylinder and the light pipe scale layer, without the power off. |

One Of Reference Drawing |

|

| FIN TUBE REFERENCE | |||||||

| TYPE | NAME | BARE TUBE MATERIAL | FIN TUBE MATERIAL | BARE TUBE DIAMETER (MM) | FIN SPECIFICATION (MM) | ||

| FIN PITCH | FIN HEIGHT | FIN THICK | |||||

| EMBEDDED | G-TYPE FIN TUEB | CARBON STEEL COPPER,STAINLESS STEEL,ALLOY | ALUMINUM | 16-63 | 2.1-5 | <17 | ~0.4 |

| EXTRUDED | SINGLE METAL COMBINED METAL | CARBON STEEL, COPPER STAINLESS STEEL,ALLOY | COPPER ALUMINUM | 8-51 | 1.6-10 | <17 | 0.2-0.4 |

| LOW FIN TUBE T-TYPE FIN TUBE | CARBON STEEL, COPPER STAINLESS STEEL,ALLOY | / | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| BAMBOO TUBE CORRUGATED TUBE | CARBON STEEL,COPPER STAINLESS STEEL | / | 16-51 | 8-30 | <2.5 | / | |

| WOUND | L/KL/LL TYPE FIN TUBE | CARBON STEEL, COPPER STAINLESS STEEL,ALLOY | COPPER ALUMINUM | 16-63 | 2.1-5 | <17 | ~0.4 |

| STRING | STRING FIN TUBE | ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL | ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-TYPE | U-TYPE TUBE | CARBON STEEL,COPPER STAINLESS STEEL | / | 16-38 | / | / | / |

| WELDING | HF-WELDING FIN TUBE | CARBON STEEL, ALLOY STAINLESS STEEL | CARBON STEEL, ALLOY STAINLESS STEEL | 16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH TYPE FIN TUBE | CARBON STEEL, ALLOY STAINLESS STEEL | CARBON STEEL, ALLOY STAINLESS STEEL | 25-63 | 8-30 | <200 | 1.5-3.5 | |

| STUDED FIN TUBE | CARBON STEEL, ALLOY STAINLESS STEEL | CARBON STEEL, ALLOY STAINLESS STEEL | 25-219 | 8-30 | 5-35 | Φ5-20 | |

| Q1:Are you a factory or trade company? |

A1: A Factory and A subsidiary international trade company for export.

|

| Q2: What can you provide? |

A2: Our company is a professional manufacturer for Radiator and Heat Exchanger Equipment and various Fin Tubes.

|

| Q3:Where is your factory? |

A3:Our company’s processing center is located in Zhangjiagang city, Suzhou, Jiangsu province , China, which is well equipped with kinds of machines.

|

| Q4: How do you control quality? |

A4: Inspection & Guarantee Certificate is supplied with shipment, and the Third Party Inspection is available.

|

| Q5: What are the advantages of your company? |

A5: We have many professional and technical personnel, more competitive prices and better after-dales service than other companies.

|

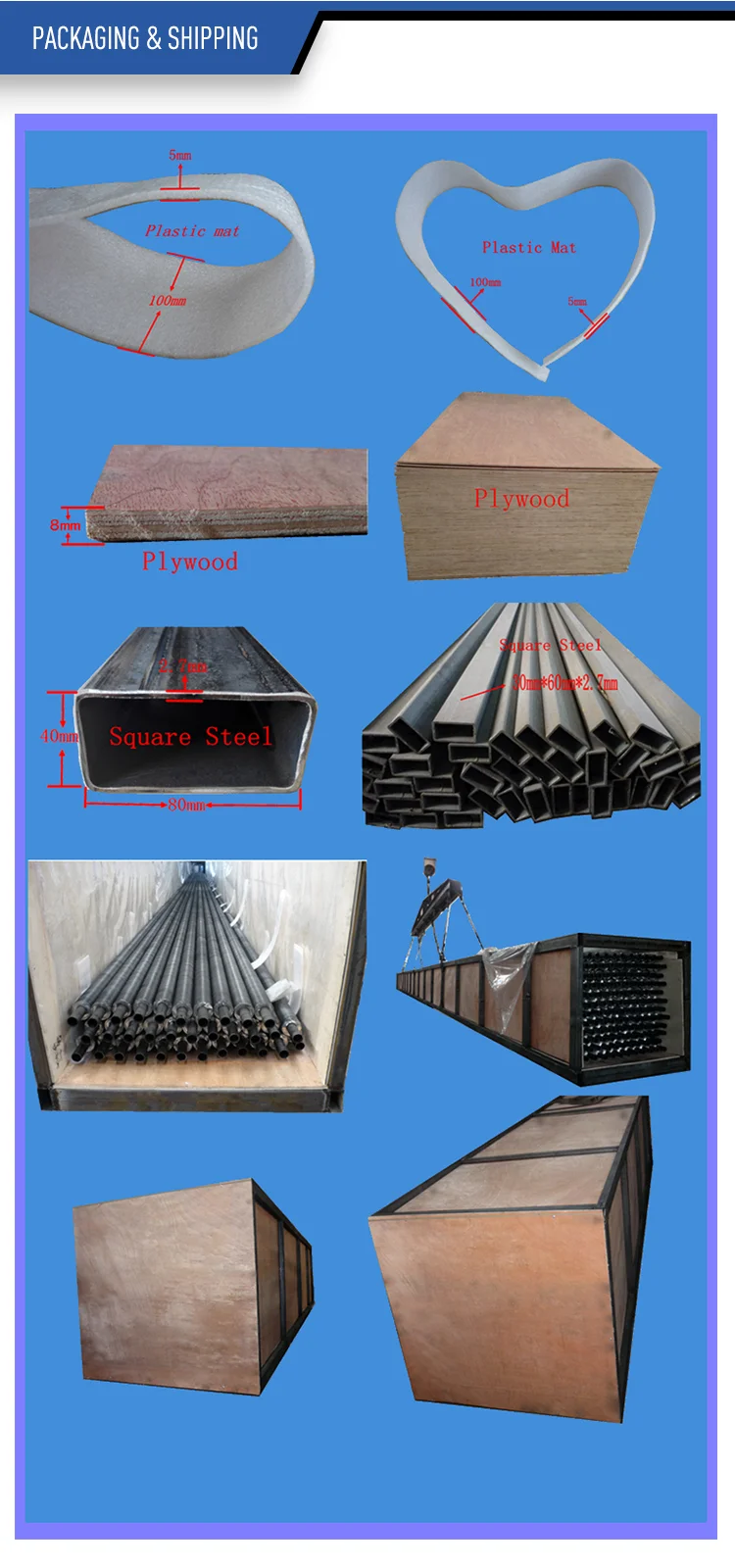

| Q6: Can you arrange the shipment? |

A6: Sure, we can help you with the shipment. We have forwarders who have cooperated with us for many years.

|

| Q7: How about the delivery time? |

A7: It is based on the order, normally within 30 days after receiving your advance payment.

|

| Q8: Can you provide sample? |

A8: Small samples in store can be provided for free.

|