Brand Name: Yongda

Model Number: WZP-120KW

Place of Origin: Henan, China (Mainland)

120KW Steel bar and billet hot forging induction heating machine

Features of induction heating machine

Heating fast: this is the heating rate of less than 1 second (speed adjustable speed control)

Heating wide: wide range of metal parts can be heated (according to the different shape of the workpiece replacement of removable induction loop)

Easy installation: connect the power, induction loop and out of the water can be used; small size, light weight, easy to use

Simple operation: a few minutes to learn

Start fast: you can start with water after the heating power

Low power consumption: high-frequency device than the old-fashioned tube about 70% energy saving, the smaller the power consumption of the smaller parts

Good effect: the heating is very uniform (also by regulating the induction coil density, so that all parts of the workpiece to obtain their desired temperature), heating up fast, less oxide layer after annealing without waste

Adjustable power: The Promise adjust the output power

Protection all: with over voltage, over current, overheating, lack of water and other alarm indicator, and automatic control and protection

Steel bar and billet hot forging, rolling induction heating machine

Technical parameters of WZP-120 KW induction heating machine

|

WZP-120 KW

induction heating generator 1 piece transformer 1 piece |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V |

Input current |

6-200A |

Input power |

6-120KW(power adjusted stepless) |

Oscillation frequency |

10-50 KHZ |

Cooling water pressure |

0.3 MPA |

Size of geneartor: Transformer |

850*600*1330MM 780*540*520mm |

Weight of generator ; transformer |

131kgs; 89kgs |

Water cooling protection point |

Below 50 degree celsius |

Accessories |

Induction coils Foot pedal 1 piece Water shunt valve 1 piece Water hose (standard configuration) User manual and product brochure 1 piece |

Control panel of our induction heating machine

Protect full.Over current.over voltage,lack of phase,water shortage, etc. more than ten alarm lamps.

Applications of steel bar induction heating machine

1. Hot forging, rolling,bending class

1.1 The variety of hot-rolled twist drill.

1.2 standard parts, hot forging fasteners, such as high strength bolts, nuts and so on.

1.3 drill steel, tempering brazing, forging, extrusion heating.

2. Heat treatment Class

2.1 The various hardware tools, hand tools, heat treatment. Such as pliers, wrenches, screwdrivers, hammers, axes and so on.

2.2 kinds of auto parts, motorcycle accessories high-frequency quenching. Such as: crankshaft, connecting rod, piston pin, crank pin, wheel, camshaft, valves, all kinds of rocker arm, rocker shaft; transmission of various gears, spline shafts, drive axle, a variety of small axes, a variety of fork and other high-frequency quenching.

2.3 power tools on the gears, shafts and other high-frequency quenching.

2.4 a variety of hydraulic components, pneumatic components of high frequency hardening heat treatment. Such as the piston plunger, rotor pump rotor on a variety of valves for the shaft, the gear pump gear, etc. quenching.

2.5 Heat treatment of metal parts. Such as the various gears, sprockets, all kinds of shafts, spline shafts, pins and other high-frequency quenching.

2.6 Machine tool industry guide, tools swallowtail quenching treatment.

3. Other

Such as precious metals smelting. Such as melting gold, silver, etc.

Induction coils is tailor-made.

Company products:

Medium frequency induction heating machine IGBT and KGPS SCR

High frequency (Super audio ) induction heating machine

Induction hardening machine, induction forging machine,induction brazing machine, induction annealing furnace,

Electromagnetic induction heating equipment,Induction melting furnace ;

CNC hardening machine tool,Automatic feeding steel rods machine,

Round bar,steel pipe induction hardening and tempering equipment

Concrete pump pipe dedicated quenching machine,Hydraulic cylinder cladding equipment;

Closed cooling tower,etc.

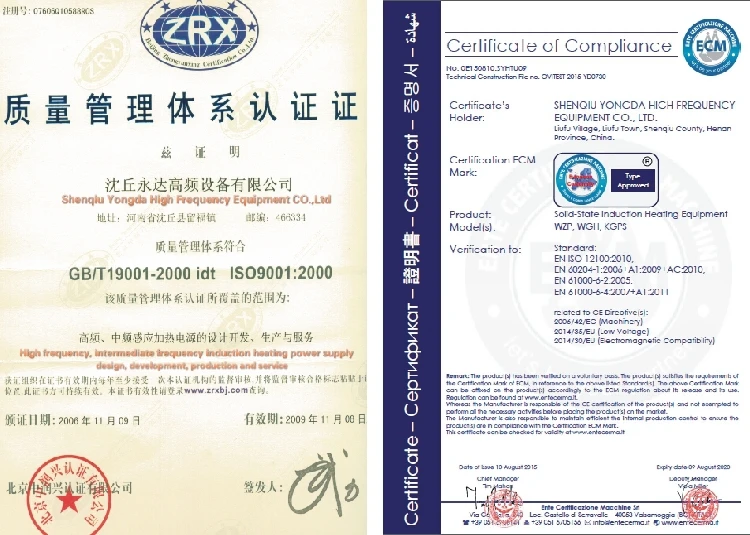

ISO,CE certification

Oversea customers visit us

Packing of induction heating machine

1.Wooden cases (plywood), as you required.

2.Inside,will be filled with plastic foam,for waterproof and shockproof.

3.Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air/train/courier

1.One year free replacement spare parts

2.Provide long-terms technical support

3.About installation: provide install technical skecth, install and operating instruction, or send engineer to helps if need.

4.About spare parts: beyong warranty period, you can buy spare parts from us with very low cost.

Over 20 years manufacturer of induction heating machine, shenqiu yongda high frequency equipment co.,ltd is your smart choice.