Brand Name: Yongda

Model Number: WZP-120

Place of Origin: Henan, China (Mainland)

Two sets 65KW steel bar two head induction heating forging machine

Technial parameters of WZP-120/65KW two head induction heating forging machine

| Model | WZP-120 |

| Work power | 3 phase 380V+/-10%, 50-60HZ |

| Input voltage | 320V-420V can be changed, depend on your country's electric power |

| Input current | 6-120A |

| Input power | 3-65KW adjustable stepless |

| Oscillation frequency | 15-30KHZ also can be changed, depend on your work pieces size |

| Size of generator | 665*400*730mm |

| Size of transformer | 660*490*435mm |

| Weight of generator | 48kgs |

| Weight of transformer | 66kgs |

| Cooling water pressure | 0.3 MPA |

Advantages of two head induction heating forging machine

1.Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2.Phase locking looping technology and soft switch ensure good reliability, realize power and frequency tracking automatically.

3.Diode rectifier cause high power factor more than 0.95

4.Working continuously with 100% duty cycle, power can be instantly turned on or shut off.

5.Perfect protective circuit and cooling system design, which ensure the good reliability of machine.

6.Low energy consumption: Converts up to 97.5% above of the expended energy into useful heat. energy saving 15%-30% compared with SCR induction heating machine.

7.Environment friendly, clean, non-polluting process which will help protect the environment, improves working conditions for your employees by eliminating smoke, waste heat, noxious emissions and loud noise.

8.Operating and installation easily and safely, installation can be done by unprofessional person very easily.

9.Can subsititue traditional heating methods.

Applications of two head induction heating forging machine

1. Hot forming/forging of the standard components and fasteners

2. Hot forging of the automobile and motorcycle parts, metallic tools

3. Hot forging of embryo gear parts

4. Heat distortion of pipes

5. Other forging applications.

6. Suitable for workpiece with various shape and different diameter

7. Customized forging production solution

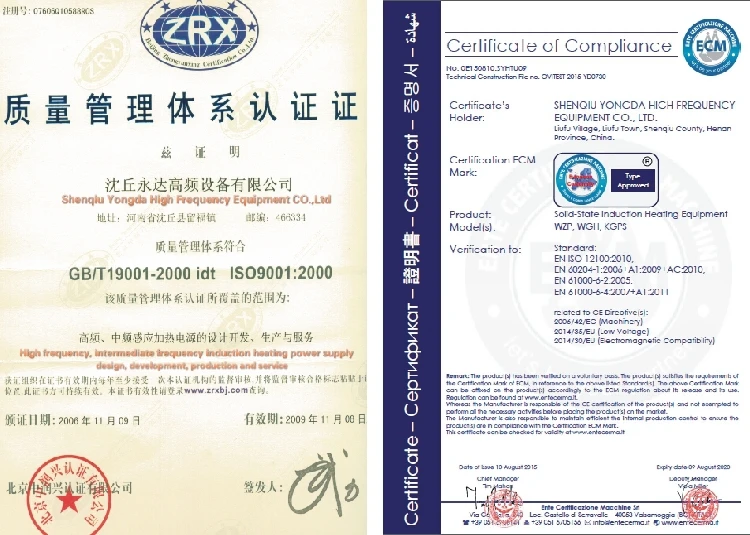

ISO and CE certification

Our fairs