Brand Name: LNEYA

Model Number: SUNDI-10A15W

Place of Origin: Jiangsu, China (Mainland)

Typical Applications

Reactor Systems Autoclaves

Pilot Systems

Double wall reactors

Advanced-Flow Reactors

Material Testing

Semiconductor Industry

Vacuum Chambers

Advantages & Functions

Working temperatures from -100℃ to +350℃

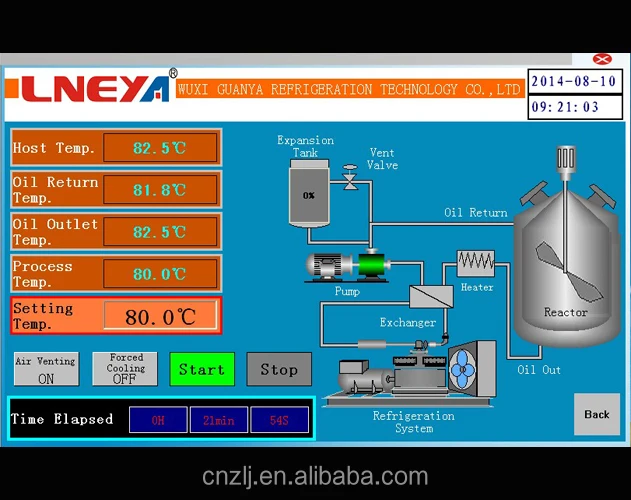

Intelligent temp. control

Max. process stability

Plate heat exchager

Closed system

Touch screen display

Warning and safety functions

Rapid cooling

Magnetic drive pump

Structure design

A fully closed piping design, high efficiency plate heat exchanger used to reduce the

demand for the thermal fluid utilization while providing the system to achieve the rapid

ups and downs in temperature.

Displays various information on the touch screen.

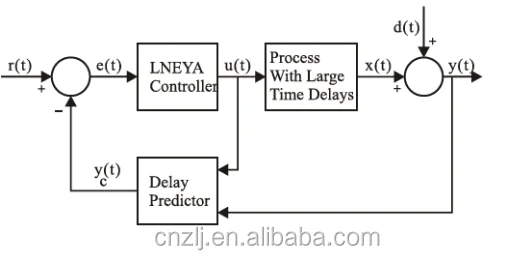

Process Control Schematic diagram

High repetative of tempeature control effect

Each cycle curve slope is consistent and greatly improve the consistency of production thermostatically control environment.

Technical Parameters

Model |

SUNDI-10A15W |

SUNDI-10A25W |

SUNDI-10A38W |

|

Temperature range ℃ |

-90℃~250℃ |

|||

Controller |

Feed forward PID +Our special dynamic control calculation, PLC controller |

|||

Communication |

MODBUS RTU Protocol, RS 485 Interface |

|||

Temp. control |

Process temperature control mode |

|||

Program Editor |

20 programs, each program can edit 45 steps. |

|||

Temperature feedback |

Heat-conducting medium feedback PT100, (oil outlet temperature, oil inlet temperature and heater temperature) ,Three temperature measuring points. |

|||

Process Temperature feedback |

Raw material process feedback PT100 or 4~20mA input (optional) |

|||

Process Temp. accuracy |

±1℃ |

±1℃ |

±1℃ |

|

Heating power |

15kW |

25kW |

38kW |

|

Cooling capacity |

250℃ |

15kW |

25kW |

38kW |

100℃ |

15kW |

25kW |

38kW |

|

20℃ |

15kW |

25kW |

38kW |

|

-20℃ |

15kW |

25kW |

38kW |

|

-40℃ |

15kW |

25kW |

38kW |

|

-60℃ |

9kW |

15kW |

22.8kW |

|

-80℃ |

5kW |

8kW |

12.5kW |

|

-90℃ |

3kW |

4.8kW |

7.5kW |

|

Circulation pump |

Max110L/min 2.5BAR |

Max150L/min 2.5BAR |

Max250L/min 2.5BAR |

|

Compressor |

Bock |

Bock |

Bock |

|

Evaporator |

KAORI Plate heat exchanger |

|||

Oil separator |

Emerson |

|||

Expansion valve |

Emerson |

|||

Operation panel |

Optional 7-inch color touch screen controller, temperature curve record, data export to excel format. |

|||

Safety protection |

Self-diagnosis function; freezer overload protection; high pressure switch, overload relay, thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. |

|||

Closed |

The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature. |

|||

Refrigerant |

R-404A R23 R14 mixed Refrigerant |

|||

Connection size |

DN25 PN10 |

DN32 PN10 |

DN40 PN10 |

|

Water-cooled type W (cooling water at 25℃)

|

12m³/h 1.5bar~4bar |

20m³/h 1.5bar~4bar |

30m³/h 1.5bar~4bar |

|

water-cooled condenser |

Shell and tube exchanger(standard) |

|||

Dimension |

2000*1000*1750 |

2300*1450*1750 |

2300*1450*1750 |

|

Weight |

950kg |

1300kg |

1700kg |

|

Power |

AC380V 50HZ 34kW (max) |

AC380V 50HZ 53kW (max) |

AC380V 50HZ 75kW (max) |

|

Case material |

SUS 304 |

SUS 304 |

SUS 304 |

|

Optional |

Optional Ethernet interface, configure the computer operating software |

|||

Optional |

Water condenser use plate heat exchanger (request for high quality water) |

|||

Optional power |

440V~480V 60HZ three-phase |

|||

2008 The first generation of refrigeration and dynamic temperature control system.

2009 Developed the second generation of refrigeration and heating thermostat.

2010 Established WUXI GUANYA REFRIGERATION TECHNOLOGY CO., LTD.

2012 Single compressor having multiple circulation systems is applied SUNDI and LT series.

2014 Developed with large capacity of ultra-low temperature freezer

2016 low temperature freezer, plate freezer into the market