Brand Name: MGREENBELT

Model Number: MG-80WS

Place of Origin: Shandong, China (Mainland)

30 ton,50 ton,80 ton, Screw Water Cooled Water Chiller for Plastic Injection Machines

Features of screw air cooled chiller

Advanced Compressor

• Unit adopts Germany BITZER or Taiwan HANBELL brand semi-hermetic screw compressor. The latest 5 to 6 patented screw rotor profile with excellent efficiency for energy saving purpose

• Adjustable infinite or closely stepped capacity control, features energy efficient, stable and quiet running.

• Most advanced patented highest precision manufacturing process.

• Built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitoring, manual reset lock-out, oil temperature sensor.

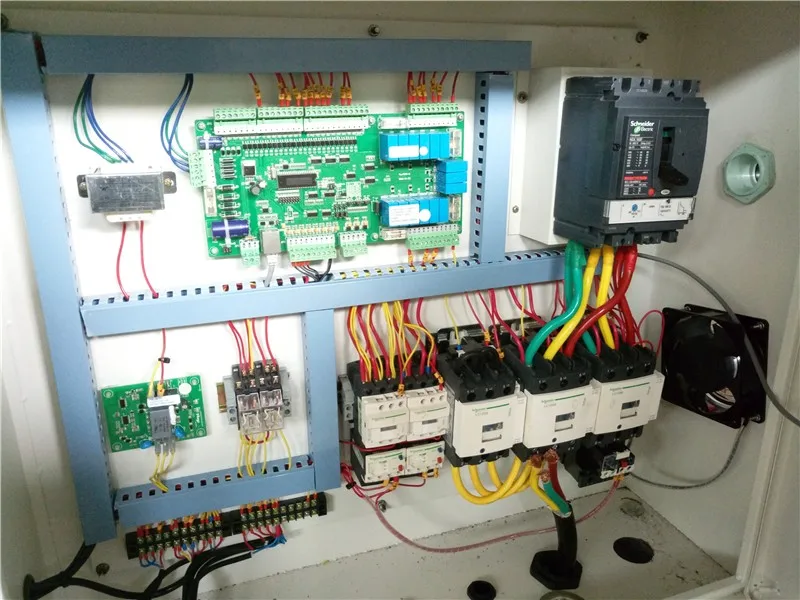

Microcomputer Control System

• Industrial PLC centralized control combined with compressor capacity control system, precisely monitor.

• Integrated protection for low temperature, high/low pressure, anti-freezing, phase missing, anti-phase, overload, motor over temperature, oil differential, flow switch, start up latency.

• Optional operation language, menu leading, unit running state easy to adjust.

• Easy Installation, Reliable Running

Features

• Shell and tube evaporator and condenser, high efficient thread red copper tube (material change on request).

• Siemens PLC control, LCD touch screen interface, easy operation, Standard design charged.

• R22, CFC free R407c, R134a for option.

380V-415V-480V/50/60HZ, 3PH for standard design. Chiller unit can be supplied according to diffierent requirements.

Specification for 20C Screw Water Cooled Chiller

| Model | MG-30WS | MG-40WS | MG-50WS | MG-60WS | MG-80WS | |

| Capacity | Tons | 30 | 42 | 54 | 60 | 80 |

| Kcal/h | 108 | 150 | 190 | 212 | 282 | |

| KW | 92863 | 128976 | 163370 | 182287 | 242476 | |

| Power Supply | 3PHASE-380V-50HZ | |||||

| Outlet Water Temperature | +5℃~+35℃ | |||||

| Refrigerant | Type | R407c | ||||

| Control Type | Thermostatic expansion valve | |||||

| Compressor | Type | Semi-hermetic screw type | ||||

| Power(kw) | 24 | 31 | 39 | 43 | 64 | |

| Start mode | Y-delta | |||||

| Energy Control | 25-50-75-100(%) | |||||

| Evaporator | Type | Shell and tube type | ||||

| Flow rate(m³/h) | 18.5 | 25.7 | 32.5 | 36.3 | 48.3 | |

| Inlet/Outlet Dia.(mm) | DN50 | DN65 | DN80 | DN80 | DN80 | |

| Condenser | Type | Shell and tube type | ||||

| Cooling water Flow(m3/h) | 25 | 35 | 44 | 49 | 65.2 | |

| Inlet/Outlet Dia.(mm) | DN65 | DN80 | DN80 | DN80 | DN100 | |

| Dimension | L(mm) | 2300 | 2500 | 2500 | 2500 | 3200 |

| W(mm) | 750 | 750 | 750 | 750 | 800 | |

| H(mm) | 1500 | 1500 | 1500 | 1500 | 1500 | |

| Weight | kg | 660 | 700 | 800 | 975 | 1250 |

| Protection System | High/Low Pressure protection , Phase-sequencing Protection, Overload Protection, Overheat Protection, Water flow protection , Anti-frozen protection | |||||

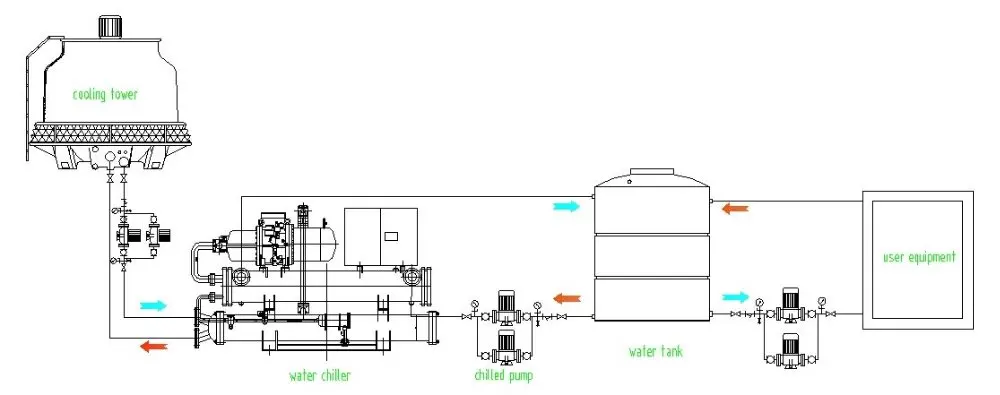

Cooling system not only includes water cool chiller, it is Water Tank, Cooling Tower, Water Pumps.

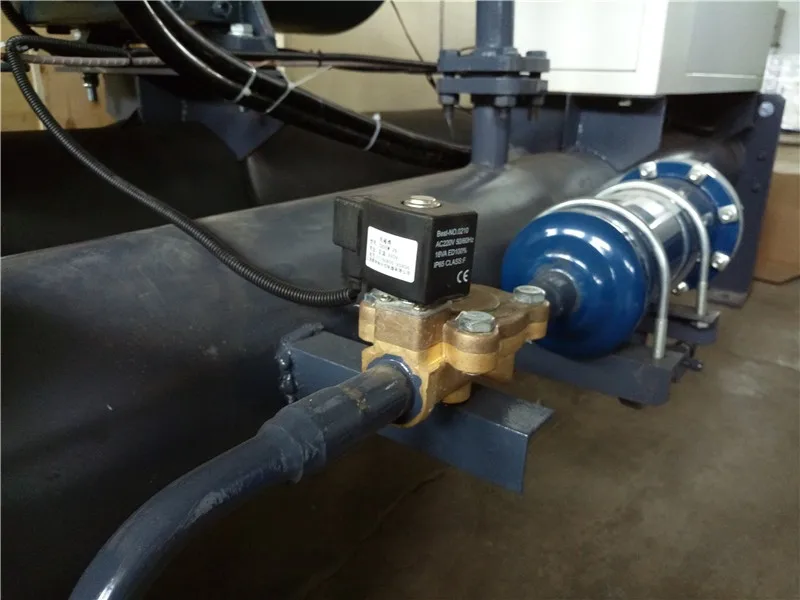

Finished screw water cooled chiller photos

Application industry

Water cooled chillers are widely used in plastic injection, extrusion, plating, molding, hydraulic, chemical, leather, printing, profiles of oxidation, reaction kettle, chemical fiber, vacuum coating, paper making, textile, central air conditioning and various aspects of water supply.

Different series chiller for your reference