Brand Name: HX

Model Number: FP

Place of Origin: Tianjin, China (Mainland)

floor standing vertical mounted fan coil stand fan with remote control

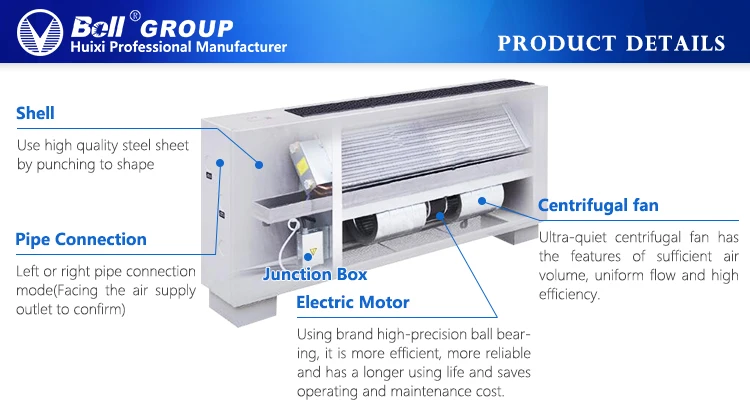

The FP series water chilled fan coil units are designed specially to meet the varied requirements of zone cooling or heating using chilled water or hot water. Fan coil can be applied to two or four pipe systems to satisfy the requirements of a wide variety of air conditioning or heating application. The FP series is available in concealed and exposed versions for ceiling and floor installation. This unit is presented as a single block including: fan deck, cooling and/or cooling coil, removable filter, drip tray, electrical connection box and decorative cabinet (excluded for concealed version).

Fan Coil Unit Picture

Fan Coil Unit Parameter

Model |

FP-34 |

FP-51 |

FP-68 |

FP-85 |

FP-102 |

FP-136 |

FP-170 |

FP-204 |

FP-238 |

||

Rated Air Flow(m³/h) |

H |

340 |

510 |

680 |

850 |

1020 |

1360 |

1700 |

2040 |

2380 |

|

M |

260 |

390 |

510 |

640 |

770 |

1020 |

1280 |

1530 |

1790 |

||

L |

170 |

260 |

340 |

430 |

510 |

680 |

850 |

1020 |

1190 |

||

Rated Cooling Capacity (KW) |

H |

1.98 |

2.8 |

3.87 |

4.58 |

5.42 |

7.38 |

9.08 |

11.1 |

12.9 |

|

Rated Heating Capacity (KW) |

H |

3.39 |

4.5 |

6.35 |

7.45 |

9.22 |

12.4 |

16.3 |

19.5 |

20.2 |

|

Input Power(W) |

12Pa |

H |

34 |

46 |

55 |

70 |

87 |

117 |

140 |

181 |

223 |

30Pa |

H |

42 |

56 |

70 |

81 |

101 |

149 |

165 |

202 |

241 |

|

50Pa |

H |

46 |

65 |

82 |

89 |

109 |

163 |

201 |

228 |

286 |

|

Noise dB(A) |

12Pa |

H |

36 |

38 |

38 |

40 |

43 |

45 |

46 |

47 |

48 |

30Pa |

H |

38 |

39 |

42 |

44 |

45 |

46 |

47 |

49 |

51 |

|

50Pa |

H |

40 |

41 |

43 |

45 |

47 |

48 |

50 |

53 |

54 |

|

Water Volume( Kg/h) |

350 |

510 |

680 |

800 |

980 |

1280 |

1600 |

1920 |

2230 |

||

Pressure Loss ( KPa) |

6 |

10 |

17 |

21 |

31 |

15 |

18 |

21 |

26 |

||

Motor Quantity |

1 |

2 |

3 |

4 |

|||||||

Weight (Kg) |

WA |

17 |

18 |

19 |

22 |

26 |

39 |

43 |

49 |

52 |

|

With air return box |

20 |

22 |

23 |

27 |

30 |

44 |

48 |

54 |

58 |

||

Input and output water pipe |

3/4’’ internal thread |

||||||||||

Condensate pipe |

3/4’’ external thread |

||||||||||

Power |

220V/50Hz |

||||||||||

Remark |

1. The test condition of cooling capacity is based on air 27℃ dry bulb temperature, 19.5℃wet bulb temperature, 7℃input water temperature,5℃ temperature difference. 2. The test condition of heating capacity is based on air 21℃dry bulb temperature, 60℃ input water temperature. 3. The whole system passes the 2.0MPa withstanding voltage test. The maximum working pressure is 1.6MPa. |

||||||||||

Application

1. Fan coil units are typically used in spaces where economic installations are preferred such as unoccupied storage rooms, corridors, loading docks.

2. In high-rise buildings, fan coils may be stacked, located one above the other from floor to floor and all interconnected by the same piping loop.

3. Fan coil units are an excellent delivery mechanism for hydronic chiller boiler systems in large residential and light commercial applications. In these applications the fan coil units are mounted in bathroom ceilings and can be used to provide unlimited comfort zones - with the ability to turn off unused areas of the structure to save energy.

Features

1. Compact Exterior----With a compact, graceful and robust design, this super thin unit can be concealed in a small space vertical or horizontal.

2. Low Noise----The unit features a forward-pitched low-speed centrifugal fan with wide impellers. The fan has a good dynamic balance and a stable performance, and minimizes the operation sound while ensuring enough air flow and the static pressure of outlet air by using efficient sound-dampening and heat-insulation material.

3. Efficient and Energy Saving----To maximize heat transfer and exchange efficiency, the unit features heat exchange coils made of quality copper tubes, efficient hyperbolic aluminum shutter fins , precise mechanic tube expansion and a fan with wide impellers and a high air supply capacity.

4. Easy and Flexible Installation----This type of fan coil units can be easily installed. Left-right water pipe connection can be changed freely.

5. Safe and Leakage-proof----The condensate water pan are molded as a whole (no welding line or dots) and entirely coated with fireproof material to prevent leakage. A specially designed pitch on the collector also helps ensure smooth discharge of condensate water.

Installation Display

Fan Coil Unit Main Products