Brand Name: Hll steel

Model Number: 300 Series,201 202 304 304L 316 316L

Place of Origin: Shandong, China (Mainland)

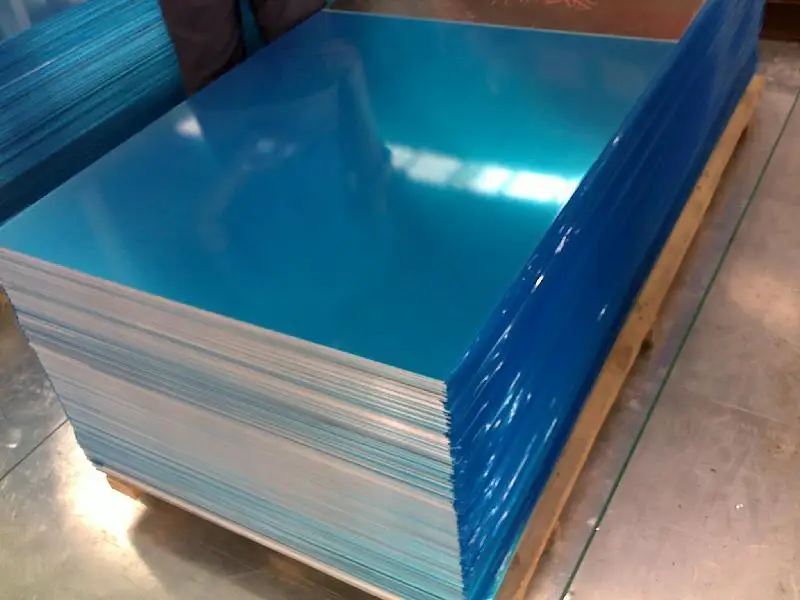

| Item name | Cold Rolled 304 Stainless Steel plate |

| Grade | 300 series |

| Type | Steel sheet |

| Standard | AISI,ASTM,DIN,GB,JIS |

| Thickness | 0.25mm-2.0mm |

| Size | 1000*2000mm, 1220*2440mm, 1250*2500mm |

| Surface | BA, 2B, HL, No.4, 8k |

| Edge | Mill edge/ slitting edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, cutlery, pots & bowls, sinks, food industry, construction decorations etc. |

| Package | Standard export package, PVC film with wooden pallet |

| Coil weight | as requested |

| Payment terms | T/T, 20% deposit in advance, balance against copy of B/L |

| Delivery time | 15-30 days after receiving the deposit |

CHEMICAL COMPOSITION % : |

||||||||||

GRADE |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

N |

Ti |

SUS430 |

≤0.12 |

≤1.00 |

≤1.00 |

≤ 0.04 |

≤ 0.03 |

16.00-18.00 |

/ |

≤0.75 |

/ |

/ |

SUS410S/ |

≤0.08 |

≤1.00 |

≤1.00 |

≤0.04 |

≤0.03 |

11.50-13.50 |

/ |

≤0.6 |

/ |

/ |

409L |

≤0.03 |

≤1.00 |

≤1.00 |

≤0.04 |

≤0.03 |

10.50-11.75 |

/ |

≤0.6 |

/ |

0.08-0.75 |

| MECHANICAL PROPERTIES (ANNEALED) | ||||||

| ITEM NO. | GRADE | 0.2% Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) | Hardness (HRB) |

| RX-SS400-1 | SUS430 | ≥205 | ≥450 | ≥22 | ≤200 | ≤89 |

| RX-SS400-2 | SUS410S | ≥205 | ≥415 | ≥20 | ≤200 | ≤89 |

| RX-SS400-3 | 409L | ≥275 | ≥415 | ≥20 | ≤200 | ≤92 |

Specifiaction

Description |

steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material |

201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness |

From 0.3mm to 100mm |

Width |

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length |

2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard |

ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application |

steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging |

Standard export sea-worthy packing |

Delivery time |

10-30 days |

Quality |

No.1 |

Productivity |

1000 tons/mouth |

Note |

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts |

If you have any question,please feel free contact me. |

Stainless steel process flow diagram

The raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

QUALITY FIRST, REPUTATION FOREMOST