Brand Name: AOBO

Model Number: AOBO-112

Place of Origin: Shandong, China (Mainland)

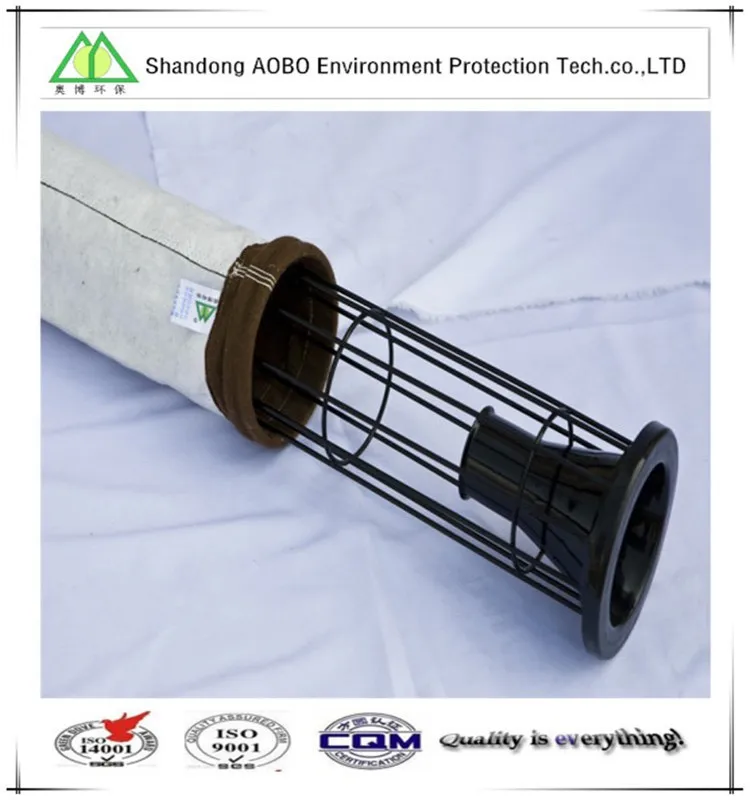

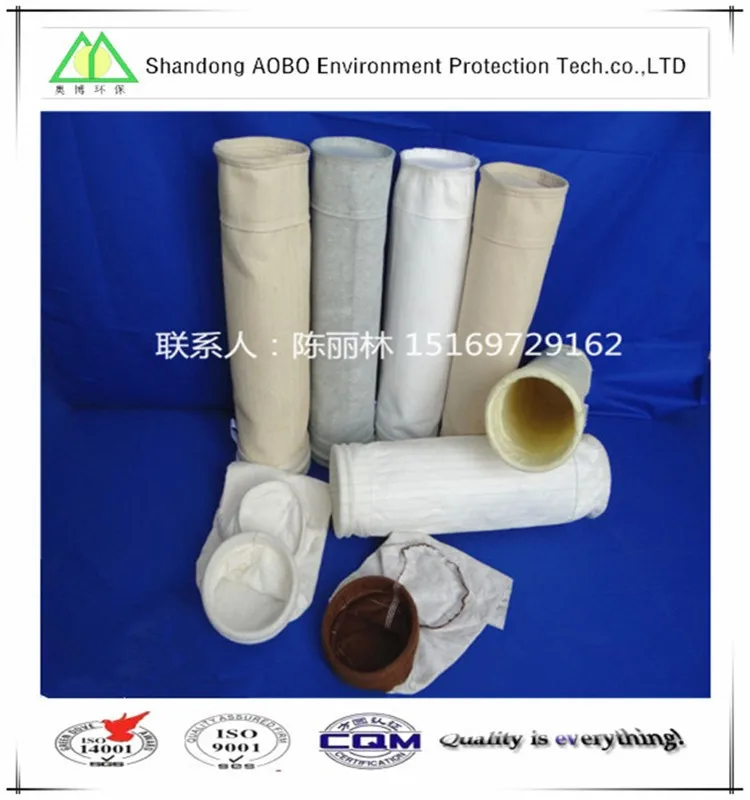

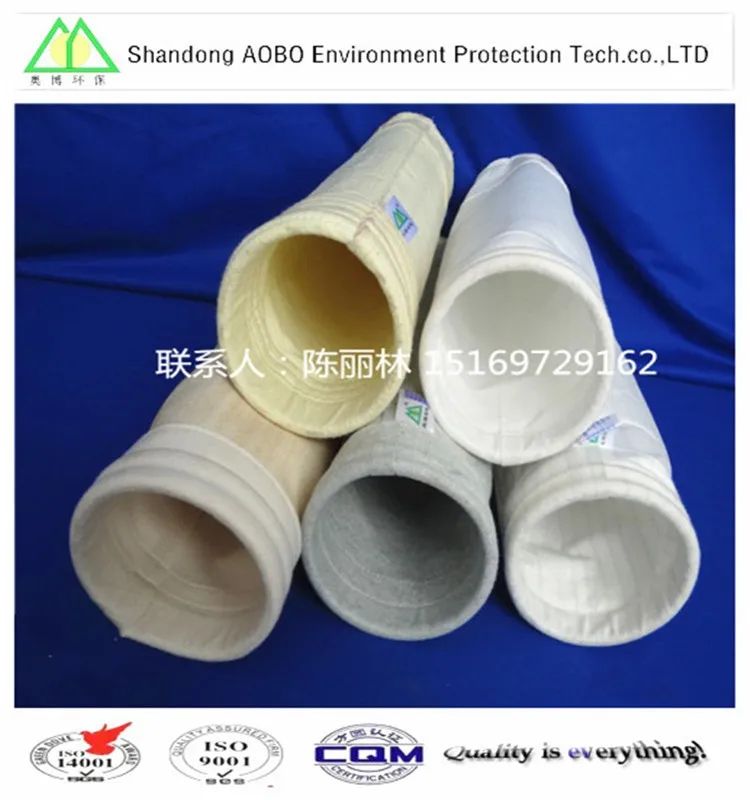

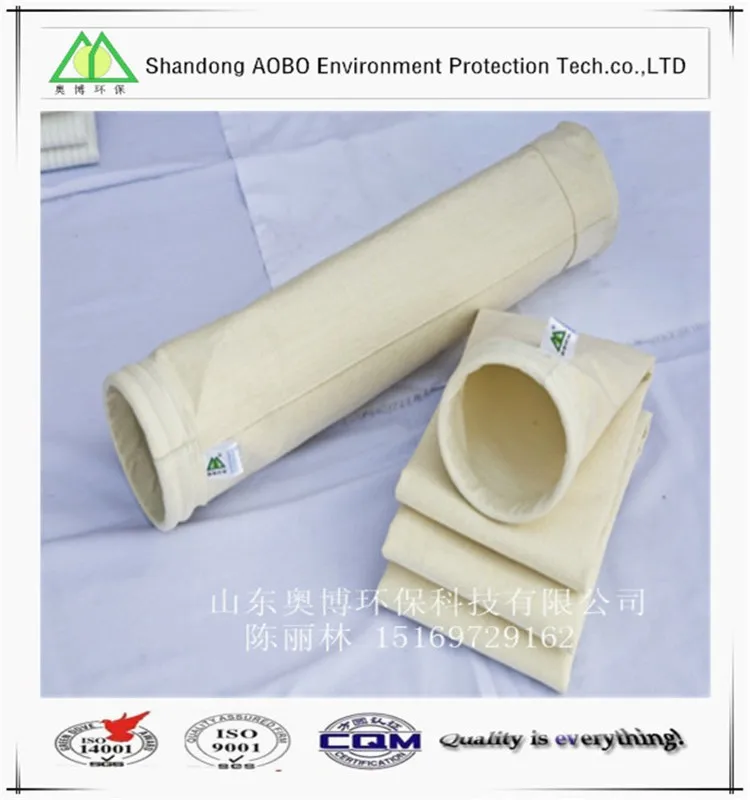

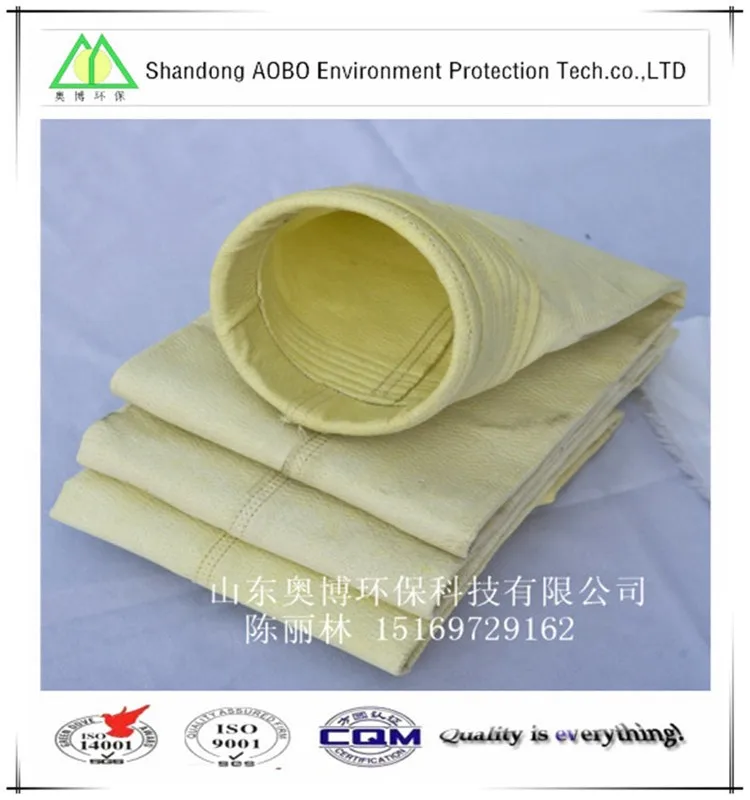

dust collector filter bag, acrylic dust filter bag, dust bag

Acrylic dust bag:

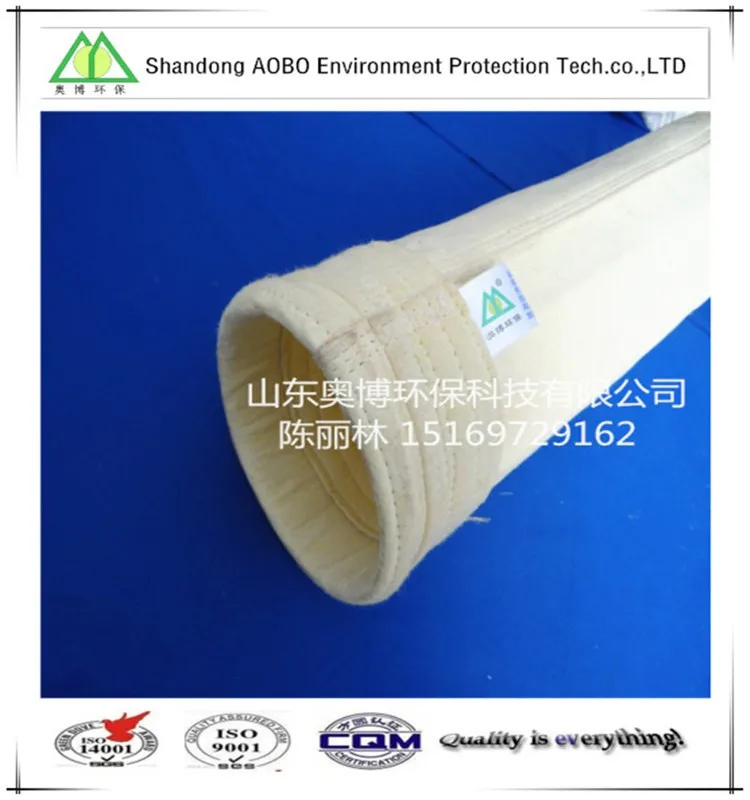

Acrylic filter has good acid, alkaline, PH value between 3-11; relative humidity less than 30%, pay attention to the oxidation Acrylic needle felt, chemical names are polyacrylonitrile, use it as raw material by needle into the legal system. felt, then through a special water-repellent treatment whereby temperature hydrolysis resistant acrylic filter needle felt. needle felt with acrylic woven fabric reinforced vertical and horizontal force as having excellent chemical resistance and hydrolysis resistance, it is widely used in garbage burning, asphalt, spray dryer dance, coal mill, power plant flue gas dust collection.

Product Features:

Pros: good hydrolysis resistance

Disadvantages: temperature resistance General

Applications:

1, foundry dust

2, low temperature and high humidity environment Dust

Product name |

Acrylic needled felt filtration material |

|

Material |

Homopolyacrylonitrile |

|

Weight(g/m2) |

500-550 |

|

Thickness(mm) |

2 |

|

Air permeability(m3/ m2/min) |

16 |

|

Tension at break (N/5×20cm) |

Warp |

>850 |

Weft |

>1200 |

|

Elongation at break (%) |

Warp |

<15 |

Weft |

<45 |

|

Working temperature (℃) |

Continuous |

130 |

Instantaneous |

140 |

|

Acid and alkali resistance |

Acid-60% H2SO4,70℃,15Hr,tension remain60% |

|

Alkali-60%KOH,50℃,15Hr,tension remain82% |

||

Shandong Aobo Environmental Protection Technology Co., Ltd. was established in 2007 with a registered capital of 50.08 million yuan, covering 150 acres, the company has advanced production equipment and scientific equipment, the main products are high temperature resistant fiber layer filter materials, filter bags, filters, bags cage and large efficient dust removal equipment, is China Association of filtration and separation unit, China's environmental protection industry backbone enterprises.

The company's existing production and R & D center construction area of 100,000 square meters, equipped with advanced detection equipment more than 30 sets. And with the Shandong Academy of Sciences Institute of New Materials, Donghua University and the National Testing Center of Northeastern University media to establish a science and technology partnership, to become co graduate workstation. The company's technology center in 2011 by the Shandong Provincial Science and Technology Department approved the construction of a "baghouse Shandong Province Engineering Research Center", in 2012 was named the Shandong Province Enterprise Technology Center. The company in 2013 was identified as provincial high-tech enterprises.

Up to now the company completed a total of four national scientific and technological innovation projects ("863", the Torch Program, a national new product plans, Innovation Fund), seven provincial innovation projects, municipal technical innovation projects more than 10, have been granted patents 15 items, including patents 4. Up to now the company involved in the preparation of national, trade and local standards made six, now existing air pollution emissions from Shandong Province is marked by the company involved in the preparation. Establishment of standards in the industry to effectively enhance the high ground, effectively gave birth to the market, to enhance the value of the products.

Rely on scientific and technological progress and constantly improve product quality, business models and constantly updated market share increased year by year, in waste incineration, iron and steel metallurgy related dust, coal-fired power plants continue to expand the scope of services involved in bag sales, manufacturing and service outsourcing equipment operators, BOT multiple channels of cooperation projects, and the success of Huaneng Power, Huadian Power International, China United Cement and other large enterprises.