Brand Name: ZG

Model Number: DZL

Place of Origin: Henan, China (Mainland)

Heavy fuel coal boilers adopts compact structure and it also has advantages: simple installation, low initial investment, safe and reliable operation, energy conservation, environmental protection, and low water quality requirement.

Heavy fuel coal boilers on textile industry is ideal thermal equipment for the industrial and aac plant because it has advantages as follows: high automatic level, high thermal efficiency, equipped with dust removal equipment, less pollution of the environment.

Heavy fuel coal boilers with combustion equipment was chain grate. Main engine is single drum longitudinal arrangement and inside of drum is a single-pass thread smoke tube. The left and right sides of the hearth is equipped with bare water wall tube, part of riser pipe forms the furnace top, and refractory brick Hanging at the bottom of the drum doesn't accept high temperature flame radiation. Drum on both sides of the lower part has two symmetrical convective pass, and water wall cured tube is assembled at 750 mm from the center line of the drum, so as to avoid tearing weld joint.

DZL two wings flue series boiler is small size but output is big. And pressure rises faster with higher thermal efficiency, which is domestic initiative. And the boilers are the national mechanical and electrical energy-saving products with national patent.

1. New furnace structure avoids to produce bulge defects which happens because of direct heating the bottom of the drum.

2. Avoid flue tube plate crack

3. New arch design for inferior coal combustion and coal adaptability

4. Independent adjustable wind chamber under the fire grate, and wind comes from two sides. Ventilated section ratio reaches 100% , and can be adjusted flexibly and air flows evenly.

5. Push-pull type damper ash removal device effectively prevents deformation of the secondary combustion and grate air leakage.

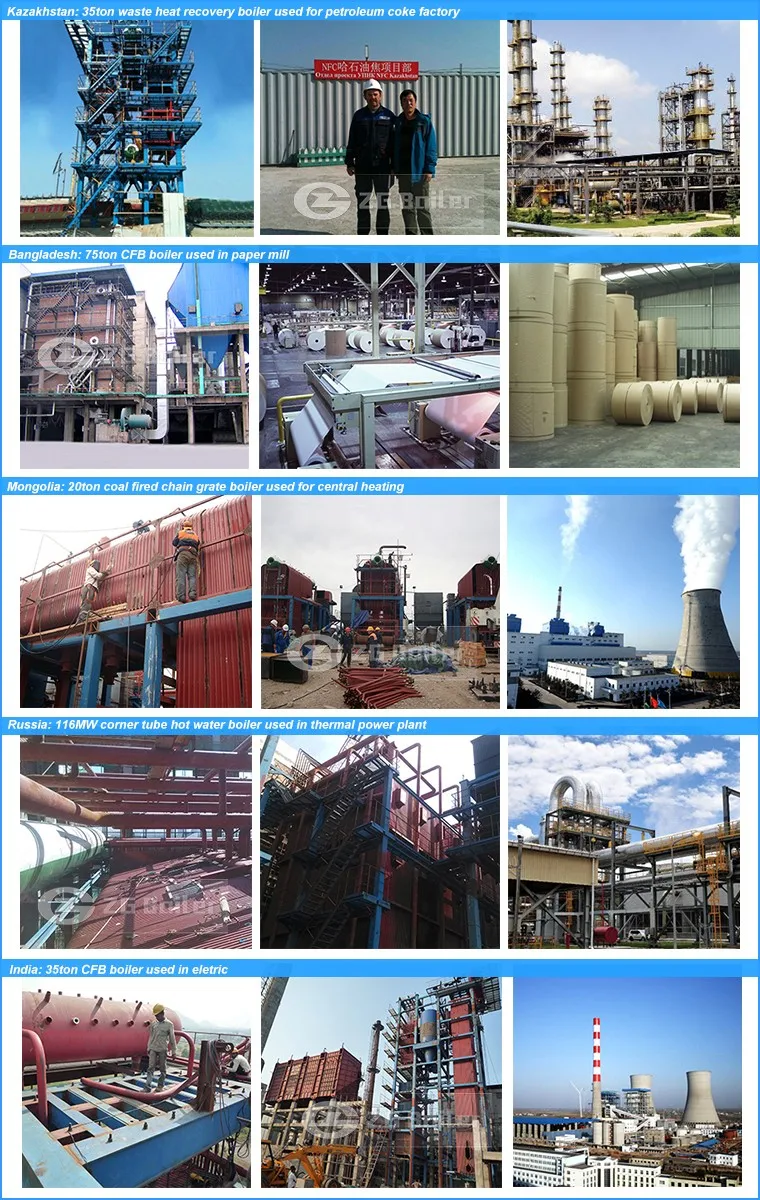

Zhengzhou Boiler Co., Ltd., formerly known as Zhengzhou Boiler factory, founded in 1945, it is the largest boiler manufacturer in central and western regions of China, boiler manufacturing license

with A-level, three types of pressure vessel manufacturing license and a boiler installation permit. In 2002 the company moved to Zhengzhou High-tech Industrial Development Zone, in 2007 again in Zhengzhou Xing Yang Development Zone covers an area of 450,000 square meters built a second factory for the company's further. Engaged in the boiler as a domestic first-class production of large enterprises.

ZG product quality has been the unremitting efforts of high returns. In 1999, once passed the ISO9001 international quality management system certification; in 2002 obtained the International Certification of quality management certification, and successfully passed the international quality management system 2000 version of call-up; in 2008 the company received the industry's most authoritative in the international arena-The ASME quality system certification, and has excellent access to equipment management unit of Ministry of Machine Building Award, Quality Management Award in Henan Province, the National boiler industry users appraisal "quality, reputation, service" Best Award , etc.

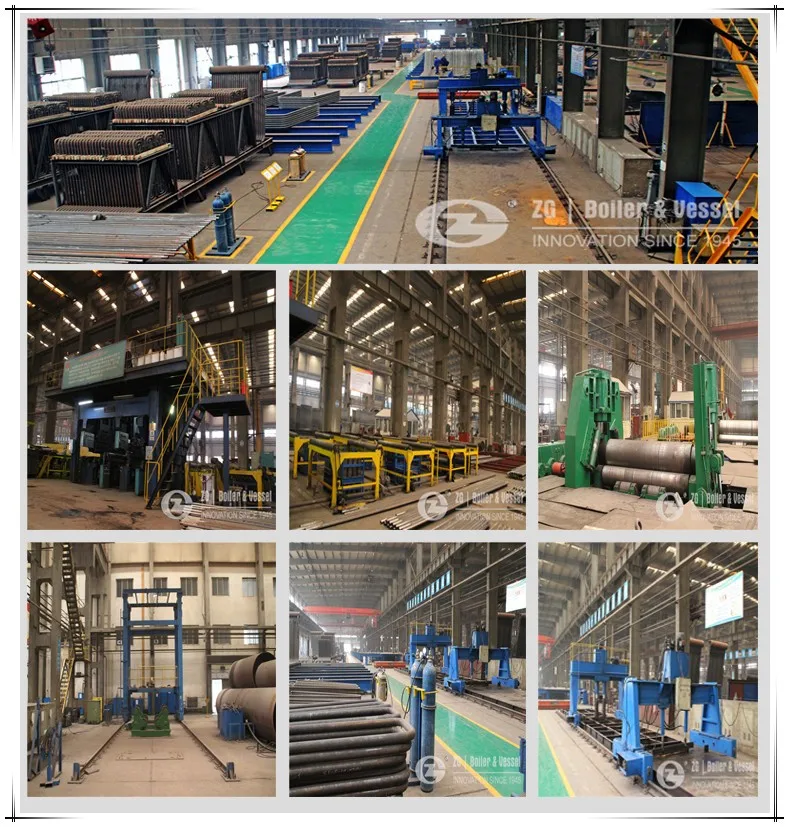

ZG Boiler adopts international standards to build large-scale union steel cross steel structure, good lighting, reasonable layout for Heavy fuel coal boilers. The factory is well-equipped, has more than 1200 sets various types of equipments, among them 428 sets of major equipments. The key production equipments include two production lines of 20 end diaphragm wall and 6 end membrane wall, Serpentine pipe automatic welding operation machines, 1400mm gas burning car-bottom heat treatment furnace, 1600mm and 800mm rows tube bending machines, IFbender, cutting machines, CNC cutting machine, automatic submerged arc welding machine, 100mm radial drilling machine, automatic welding machine, etc. The technological equipments are in the domestic advanced level.

Our Heavy fuel coal boilers accessories have uinque advantages:

1. Drums:

1) Ligament Efficiencies and Corrosion Allowances that Meet or Exceed ASME Code

2) Up to 3 Stages of Internal Moisture Separation for Most Stringent Steam Purity Requirements

3) Internal distribution piping to provide positive circulation

2. Furnace:

1) Water Cooled Membrane Wall Construction (Including Front and Rear Walls as Specified

2) Appropriate Heat Releases for the Application

3) Sized for Flame Dimensions to Achieve Best Possible Emissions

4) Minimal Refractory to Reduce On-Going Maintenance

5) Fully Accessible for Inspection

6) All Tubes Connected Drum to Drum with No Intermediate Headers

3. Superheater:

1) Both Radiant-Convective and 100% Convective Available

2) Assemblies Completely Self-Supporting (No Intermediate Support Brick Required

3) All Elements of Equivalent Length Ensuring Balanced Flow

4) Conservative Velocities Inside Tubes Assure Positive Cooling at All Loads

5) Fully Drainable

With Advanced Technology, Exquisite Workmanship, Higher Quality, and Perfect After-sale service, our products are most welcomed around the world.

For 70 years, ZG boiler is on the way of innovation with the best boiler system for the world industry.

If you want to know more about your ideal porducts, welcome to contact us at any time!!!

Email: horizontalboiler@ gmail.com

Skype: industrialboiler1945

Heavy fuel coal boilers with high efficiency 95%