Brand Name: BEDEL

Model Number: 001

Place of Origin: China (Mainland)

Production Description

ASTM A213-304 corrugated stainless steel tube heat exchanger tube

Corrugated tube (expansion wave tube)

High heat transfer efficiency

The special design of peaks and troughs makes the fluid in expansion wave tube forms a strong turbulence because of the section continuous mutation inside and outside the pipe. Even when the flow velocity is small, the fluid in the tube inside and outside all can form strong disturbance, greatly improving the heat transfer coefficient of heat exchange tube. The heat transfer coefficient of expansion wave tube is 2 ~ 3 times higher than a traditional tube heat exchanger.

non-fouling, non blockage, and non dirty, smooth operation

In the process of work, on the one hand, the media of expansion wave tube inside and outside always is in a highly turbulent state, to makes it hard for solid particles in the medium deposit scale, on the other hand, Affected by the medium temperature difference expansion wave tube may be out of shape as infinitesimal axial expansion, at the same time, the curvature of the tube inside and outside can has a change. Due to the coefficient of linear expansion between dirt and bellows tube is vary wide, a larger pulled off force between dirt and heat exchange tube will produce, so even if there are scale, they could burst up and off automatically, and keeping the heat exchanger has always been persistent and highly efficient performance. At the same time, there is no congestion because the channel is wide, the pressure drop is small, and the energy-saving effect is obvious.

Automatic compensation function

The special structure shape makes the expansion wave tube can effectively reduce the thermal stress, do not need to set expansion joint in the heat, which simplifies the structure of products and improves the reliability of the product.

Reliable, safe and strong

The existences of the peaks and troughs make the expansion wave tube axial expansion ability enhancement, effectively reduces the temperature difference stress, can adapt to the changing of the large temperature difference and pressure so that it can't be leaks of tube rupture caused by the phenomenon. With a unique connection technology, Baffle plate and bellows tube prolong the service life of heat exchanger.

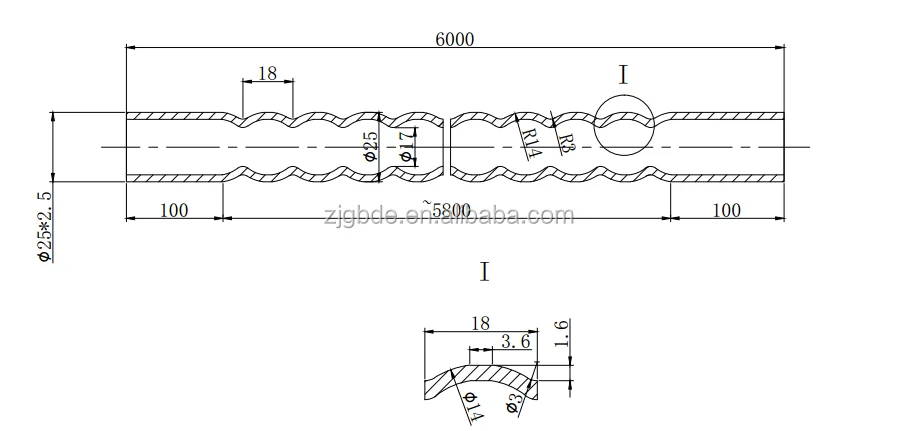

One of the drawing

| Product Name | Corrugated tube |

| Material | Copper,Copper Stainless Steel,Carbon Steel, etc. |

| Type | Extruded |

| Packing | Strong Plywood Case With Steel Frame |

| MOQ | 100 Meter |

| Warranty | 1 Year |

| Payment | T/T, L/C |

| Application | Heater, Heat Exchanger Parts etc |

Tube In Heat Exchanger Parts

Workshop

Product

Production Flow Chart

| FIN TUBE REFERENCE | |||||||

| TYPE | NAME | BARE TUBE MATERIAL |

FIN TUBE MATERIAL |

BARE TUBE DIAMETER (MM) |

FIN SPECIFICATION (MM) | ||

| FIN PITCH | FIN HEIGHT | FIN THICK | |||||

| EMBEDDED | G-TYPE FIN TUEB | CARBON STEEL COPPER,STAINLESS STEEL,ALLOY |

ALUMINUM | 16-63 | 2.1-5 | <17 | ~0.4 |

| EXTRUDED | SINGLE METAL COMBINED METAL |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

COPPER ALUMINUM |

8-51 | 1.6-10 | <17 | 0.2-0.4 |

| LOW FIN TUBE T-TYPE FIN TUBE |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

/ | 10-38 | 0.6-2 | <1.6 | ~0.3 | |

| BAMBOO TUBE CORRUGATED TUBE |

CARBON STEEL,COPPER STAINLESS STEEL |

/ | 16-51 | 8-30 | <2.5 | / | |

| WOUND | L/KL/LL TYPE FIN TUBE |

CARBON STEEL, COPPER STAINLESS STEEL,ALLOY |

COPPER ALUMINUM |

16-63 | 2.1-5 | <17 | ~0.4 |

| STRING | STRING FIN TUBE | ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL |

ALUMINUM,COPPER CARBON STEEL STAINLESS STEEL |

25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-TYPE | U-TYPE TUBE | CARBON STEEL,COPPER STAINLESS STEEL |

/ | 16-38 | / | / | / |

| WELDING | HF-WELDING FIN TUBE |

CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

16-219 | 3-25 | 5-30 | 0.8-3 |

| H/HH TYPE FIN TUBE |

CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

25-63 | 8-30 | <200 | 1.5-3.5 | |

| STUDED FIN TUBE | CARBON STEEL, ALLOY STAINLESS STEEL |

CARBON STEEL, ALLOY STAINLESS STEEL |

25-219 | 8-30 | 5-35 | Φ5-20 | |