Brand Name: Hommy

Model Number: HM116

Place of Origin: Guangdong, China (Mainland)

Hommy Enterpiese Co.Ltd

(CE approved) Frozen yogurt ice cream machine HM116)

| Model Number |

Function | Feature | Product Offering | Air pump overrun | Expension tube overrn |

pre-cooling temperature |

Hopper capacity |

Cylinder capacity |

| HM901 | PMCHDD | Desktop | Frozen yogurt ice cream & Soft ice cream | 30-40% | 2~5 degree |

13L x 2 | One 1.8 Little capacity(1.63quart,0.48gallons) | |

| HM901A | PAMCHDD | 20-80% | ||||||

| HM116 | PAMCHDD | 20-80% | 30-40% | |||||

| HM116S | PC | 30-40% | 2~5 degree |

5.5Lx1 | 1.1L |

| Model Number |

Flavour | Production Capacity |

Beater material |

Beater motor | Cooling Type |

Noise Decibel (db) |

Voltage | Touch Screen Contorl | Tap |

| HM901 | Single | 35-40L/H | One, 0.75KW(1HP) | Air cooled | Ultra quiet 50-55 db |

220V50/ 60Hz, 1phase |

Color screen (7 inch) |

Yes | |

| HM901A | Yes | ||||||||

| HM116 | water cooled | Yes | |||||||

| HM116S | 18-20L/H | 200w | Air cooled | Ultra quiet 50-55 db |

Electronic control panel | None |

| Model Number |

Guarantee Policy |

N.W | G.W | Machine Dimension(mm) Width x Depth x Height |

Packing Dimensions(mm) |

Packing | 1x20'' container |

1x40'' Container |

Certificate |

| HM901 | One year guarantee for cooling system | 280 | 330 | 452x743x893 | 639x854x1072 | Fiberboard case |

44 | 90 | CE/ETL |

| HM901A | |||||||||

| HM116 | 280 | 330 | 298×787×933 | 301x854x1072 | 44 | 90 | CE/ETL | ||

| HM116S | 55 | 60 | 779×295×661 |

Machine size

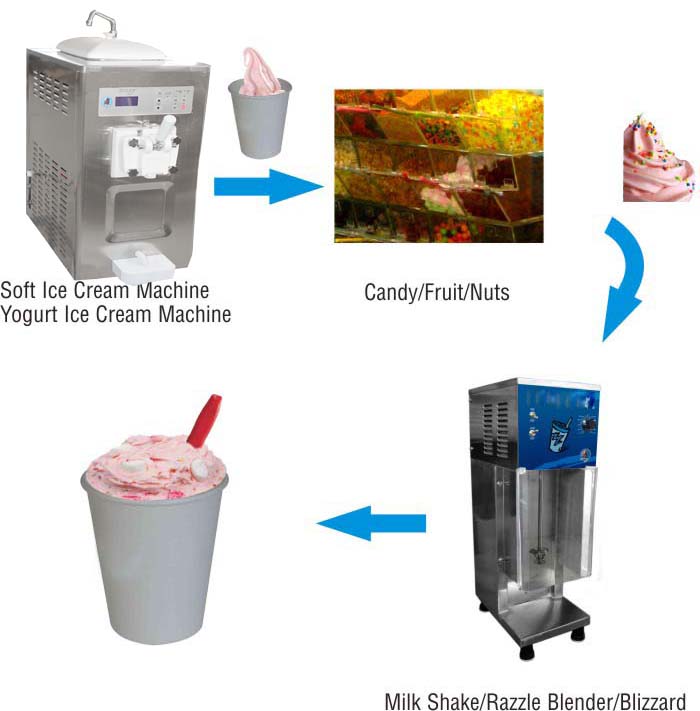

Porduct offering : offer all popular soft serve variations from ice cream to low or non-fat frozen yogurt

Flavour: signle

Mix hopper : 13 liter capacity (13.7 quart, 3.43gallons)

Freezing cylinder: 2.8Liter capacity (3 0quart,0.74gallons)

Plastic beater

Functions:

Pre-cooling,Mixer , Counter,Heat treatment,Production defrosting,Washing defrosting.Disinfection

Pre-cooling funciton (P) :

--Speed up the ice cream molding

--Adjustable pre-cooling temperature 2-5ºC.

--Effectively prevent bacterial breeding.

Keep fresh function(K): it acts as a refrigerator for tank which make the tank freezed all the way under the rated temperature.As well it promotes ideal ouput,keeps the stuff fresh and allows mixed stuff to remain in the machine over night by stand-by-switch feature,reduces labor and daily maintenance costs as the equipment only requires disassembly and cleaning once a week

Mixer(M):

--Frost prevention, improve the efficiency of the refrigeration of cylinder, reduce energy losses.

--Reducing the precipitation of raw material make our products always delicious and uniform.

--Reduce layering of raw materials, prevent from frozen cylinder phenomenon, protect the mixing shaft and motor.

Counter :Show the number of sold ice cream every day to boss and investors, convenient them knowing the sales situation.

Defrosting:

--Production defrosting repidly melts the product in both cylinder and then goes back to prduction mode to reproduce .

--Washing defrosting reapidly melts the mixture in the cylinder that significantly reduces leftovers before cleaning.

Disinfection:

-Special function that makes sanitzing process semi-automatic and easy.

-No disassemble the machine to clean the throat block unit, air pump unit,beater and cylinder .