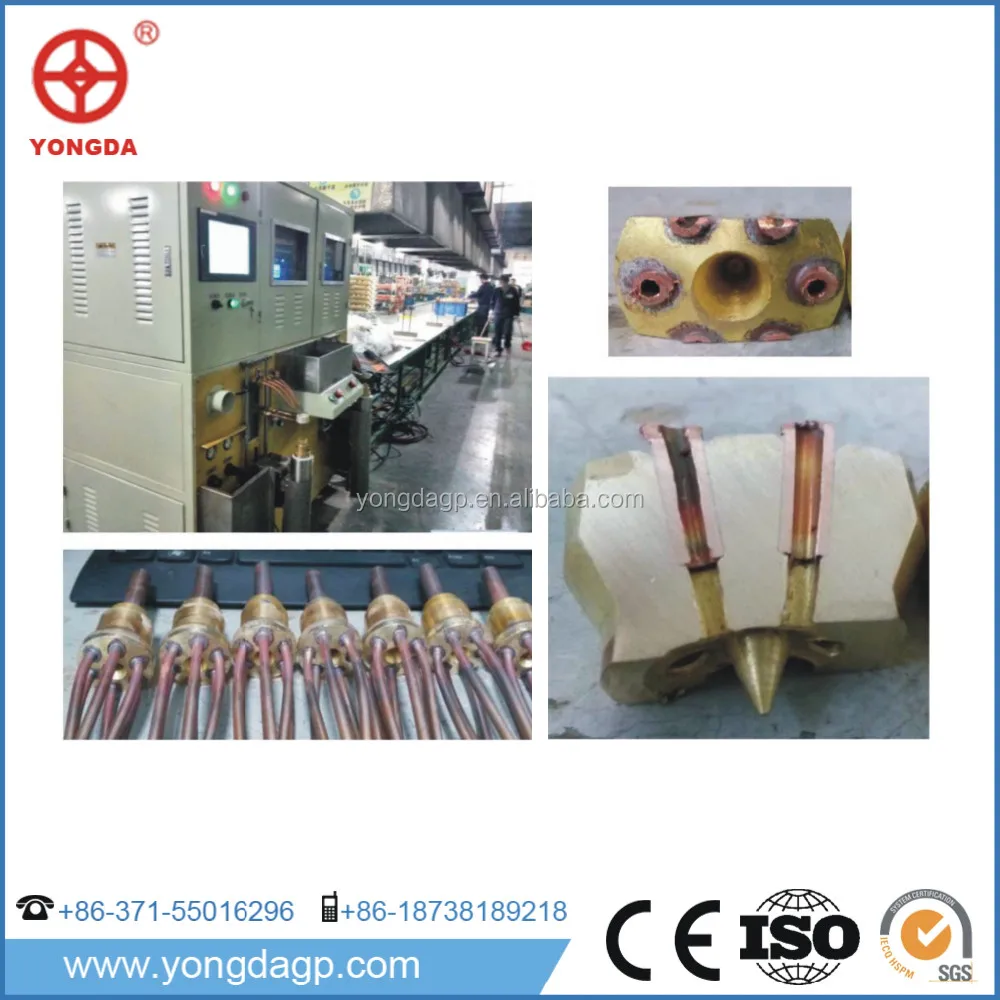

Brand Name: Yongda

Model Number: WGH-IV-36

Place of Origin: Henan, China (Mainland)

Air conditioning Branch distributor copper pipe induction brazing machine Yongda WGH-36

Air conditioning Branch distributor copper pipe induction brazing machine Yongda WGH-36

Main features of copper pipe induction brazing machine

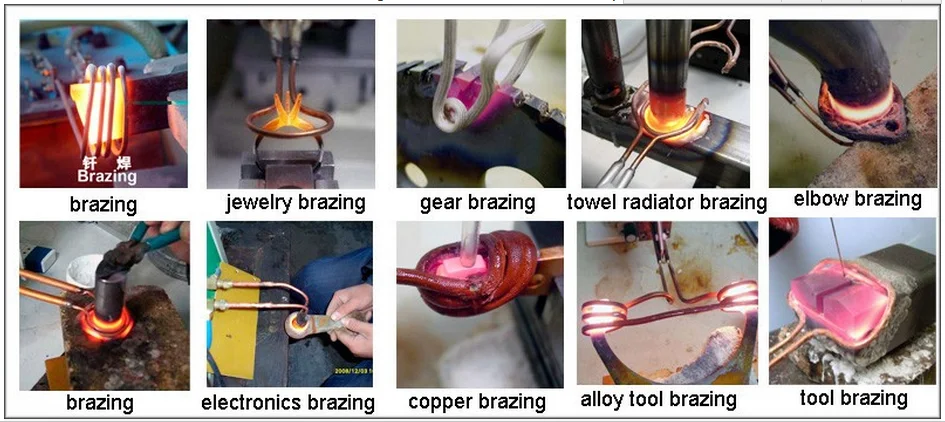

First, the high-frequency welding brazing machine welding tool can be used in alloys

For example: alloy turning, milling, planer, saw, reamer, boring and so on.

Advantages for welding alloy cutting tools:

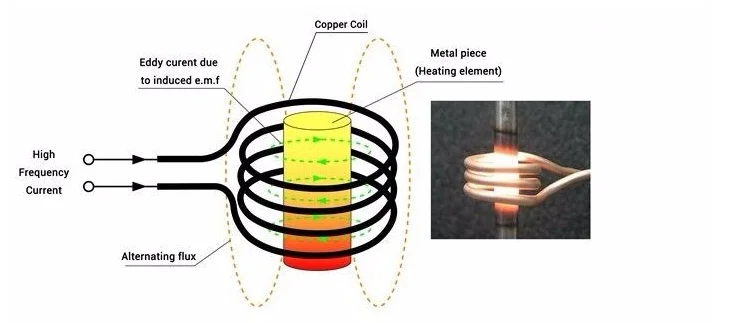

1, induction heating speed, high efficiency

2, simply put pieces of copper or silver solder between the head and the substrate can be a good place

3, energy saving and low cost

4, the oxidation of small area

5, the appearance of fine after welding

6, uniform heating, hence there is no shortage of spot welding and leakage

Second, high frequency induction brazing machine for the advantages of brazing metal parts:

1, induction heating speed, high efficiency

2, low-cost energy saving

3, one can weld multiple parts, so that the welding efficiency is improved

4, the oxidation of small size,

5, uniform heating, lack of welding and leak-free solder joints

6, the workpiece after welding appearance of fine, solid

Third, the high-frequency induction brazing machine for welding marble saw blades, wood saw blade brazing, its advantages are:

1, efficient, rapid welding gear, each tooth 1-5 seconds;

2, reproducible and have good reproducibility for each tooth;

3, heating quickly and evenly, can effectively prevent local overheating caused by jagged and brittle fracture,

Can also be caused by lack of penetration to prevent the teeth out of negative phenomena ,etc.

4, can be welded high-performance, high hardness, serrated blade, the blade can not be welded by resistance welding

5, less electricity

Model |

Input voltage (Customized) |

Input current |

Oscillation frequency |

Cooling water pressure (MPA) |

WGH-IV-16 |

Single phase 220V |

3-30A |

30-100Khz |

0.1-0.3 |

WGH-IV-36 |

Three phase 380V |

3-36A |

30-100Khz |

0.1-0.3 |

WGH-IV-50 |

Three phase 380V |

3-50A |

30-50Khz |

0.1-0.3 |

WGH-IV-60 |

Three phase 380V |

6-60A |

30-80Khz |

0.1-0.3 |

WGH-IV-80 |

Three phase 380V |

6-80A |

25-80Khz |

0.1-0.3 |

WGH-IV-120 |

Three phase 380V |

6-120A |

20-80Khz |

0.1-0.3 |

WGH-IV-160 |

Three phase 380V |

6-160A |

20-80Khz |

0.1-0.3 |

Branch distributor copper pipe induction brazing machine

Successfully Case Study:

1 Shaft hardened, hardened layer of 1.5-3mm, diameter Φ10mm-250mm, bore all kinds of quenching.

2. Φ5-Φ12 wire annealing.

3 Drill head welding.

4. Φ25 bar through the following heat, the speed is much faster than the SCR. Φ60mm-Φ100mm bar diathermy

5 kinds of chains, sprockets heat treatment

6. Angang 3 meters in diameter hardened gear weight 80 tons

7. Hanjiang River Bridge with Φ1016mm thickness 17.5mm steel heated to 1,000 degrees bending shape.

8. Necking forming various types of pipe heating

9. Copper annealing, wire annealing

10. Machine Tool Gears, Sprockets quenching

11. kinds of heat flared elbow necking.

12. Φ50mm 3mm thick stainless steel annealing

Packing for copper pipe induction brazing machine:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

We have ISO 9001:2008, and CE, and TUV certifications

Focus on solid state induction heating machine over 20 years, only do high quality, best service .

Please contact your customer service Jessie

Item No.: jessie170103