Brand Name: Yongda

Model Number: WZP-160

Place of Origin: Henan, China (Mainland)

90KW IGBT electromagnetic induction heating for stainless steel

Features of induction heating for stainless steel machine

Technical parameters of WZP-160 induction heating for stainless steel

Model |

WZP-160 |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V can be changed, depend on your country's electric power |

Input current |

6-160A |

Input power |

6-90KW(power adjusted stepless) |

Oscillation frequency |

15-30 KHZ |

Cooling water pressure |

0.2MPA |

Size of geneartor: Transformer |

740*403*895 735*490*465mm |

Weight of generator ; transformer |

55kgs; 74kgs |

Water cooling protection point |

Below 50 degree celsius |

Applications of induction heating for stainless steel machine

Stainless steel hardening, stainless steel tube annealing, besides, many applications as the following:

Heating (hot forging, hot fitting and smelting):

1 Hot forging aims to strength the work pieces of certain temperature (different materials require different temperatures) into other shapes through forging press with the help of punch press, forging machine or other equipments, for instances, hot extrusion of watch case, watch flan, handle, mold accessory, kitchen and table ware, art ware, standard part, fastener, fabricated mechanical part, bronze lock, rivet, steel pin and pin.

2. Hot fitting refers to the connection of different metals or metals with nonmetals through the heating based on the principle of hot expansion or hot smelting, for instances, embedded welding of copper core of computer radiator with aluminum sheet and speaker web, compound of steel and plastic tube, sealing of aluminum foil (tooth paste peel), motor rotor and sealing of tubular electric heating element.

3. Smelting mainly aims to melt the metal into liquid by using the high temperature, which is mainly applicable to the smelting of iron, steel, copper, aluminum, zinc as well as various noble metals.

Induction annealing

Standard parts forging

Shaft hardening

More heating applications

Debugging machine workshop

Product quality certifications:ISO9001-2000

Pre-sale service:

We will recommend the most applicable equipment for customers according to your work piece processing demands.

In-sale service:

(1) We will strictly produce the equipment according to relevant technical standards.

(2) We will take run test according to relevant equipment test run regulations.

(3) We will strictly inspect the equipment before delivery,only good machine will be sent to customers.

(4) We will send goods as scheduled in the contract.

After-sale service:

(1) We will freely guide installation, commissioning and test run,by sending intall drawings, sometimes calling or send email.

(2) We will execute one-year guarantee period (ex. not include normal wear, damages of wearing parts and parts damages caused by improper operation).

(3) Once there is a trouble during quality guarantee period, our company promises that we will promptly appoint engineer and sales to help, make our efforts to remove troubles and guarantee the normal operation of customers.

(4) We will freely replace all equipment parts during guarantee period. After-sale products archives and life-long repair solve the potential problems of customers.

(5) Provide long-terms technical support. Also for different work pieces , give instructions and help about how to produce inductors.

(6) According to customer’s need, can arrange engineer to install ,test machine and training operators.

(7) After guarantee period, customer can buy machine parts from us with very low cost.

Packing for induction heating for stainless steel machine

Two wooden cases (plywood) or carton,as you required.

Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

What’s your MOQ? |

Any quantity of machine will be accepted. MOQ:1 Set |

Which place your factory is located? |

We are located in Shenqiu County, Zhoukou city, Henan Province ,China |

How far from Beijing? I think it is more closer to Shanghai |

Our factory is near both and Shanghai. We have office in Zhengzhou, we can pick up you at Zhengzhou CGO airport,and then to our factory via expressway about two hours. |

We need to see some more videos for production line and also pictures of your factory, water drawing and panel drawing |

Well, we have many videos show our customer’s machine working scene(Various of applications: forging,hardening, brazing, shrink fitting, melting and hot coating etc. According to your work piece processing requirements,) send you the corresponding video link or send by email. 2. Yes, we can provide you factory pictures and machine water connection and control panel details. |

Do you have quality certifications? |

Yes, we got the ISO9001:2000 International quality management system certification in August,2001, |

How do you packing the machines? |

Standard export wooden cases(plywood) Usually every set machine will be used two wooden cases: one for packing induction heating generator, one for packing transformer. Inside will be filled with plastic foam for waterproof and shockproof |

More questions….? |

Updating… |

Stainless steel work parts heating, hardening, annealing, welcome to inquiry us !

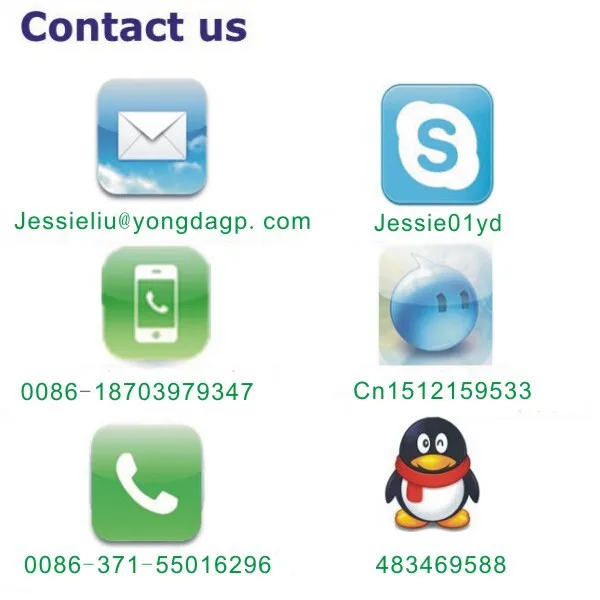

Thanks for your reading ! Welcome to contact us !