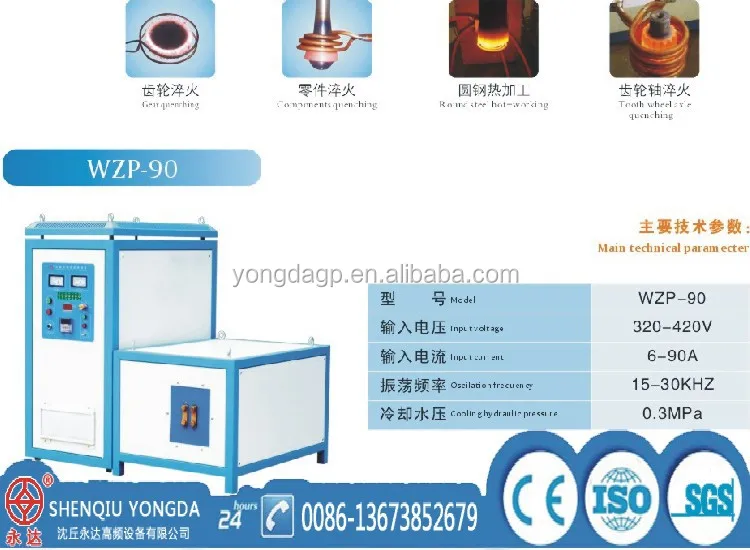

Brand Name: Yongda

Model Number: WZP-90

Place of Origin: Henan, China (Mainland)

Super audio frequency induction steel hardening furnace

Technical sepecifications of WZP-90 steel hardening furnace

Model |

WZP-90 |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V can be changed, depend on your country's electric power |

Input current |

6-90A |

Input power |

3-50KW(power adjusted stepless) |

Oscillation frequency |

10-50 KHZ |

Cooling water pressure |

0.2 MPA |

Size of geneartor: Transformer |

665*400*730mm 660*490*430mm |

Weight of generator ; transformer |

47kgs; 62kgs |

Water cooling protection point |

Below 50 degree celsius |

Induction steel hardening furnace product features:

1.control core: the use of the world's most advanced high-speed digital signal processor (HDSP), and use the ACME developed special chip as an auxiliary processor.

2.A new generation of IGBT or MOSFET as the main inverter devices, combined with fast and efficient way to control the resonant inverter efficiency greater than 95%, the host power factor greater than 0.9.

3.Air-cooled, water-cooled or dual combination of making the device more suitable for a variety of industry applications.

4.Equipment using fast and efficient resonant all-digital control, so that it can adapt to various parameters of the sensor, work in the most efficient state. Full range of power built-in digital

Word type PID temperature control module, including user-programmable thermostat curve technology, built-in 2-way 6-channel temperature or temperature.

5.Built-in programmable engineering applications IO interfaces: analog output, analog input, IO and IO input output interface, RS232 or RS485 communication interface.

6.Communication interface can be connected to a dedicated data logger.

7.Power is adjusted by stepless adjustment method, can be adjusted from 0% to 100%, using a resolution of 0.1% or 0.01% Class level, stable output of 0.3%, or 0.025%.

8.Control interface using English display, the display using the 2.7 ", 5.5" or 7.0 ", depending on the application level using no screen.

9.Optional wired, or wireless controller away (with LED display).

10.Air-cooled equipment, machine design life of more than 12 years, water-cooled equipment (except water outside) design life of more than 8 years, waterway protection using rapid water flow detection setting protection.

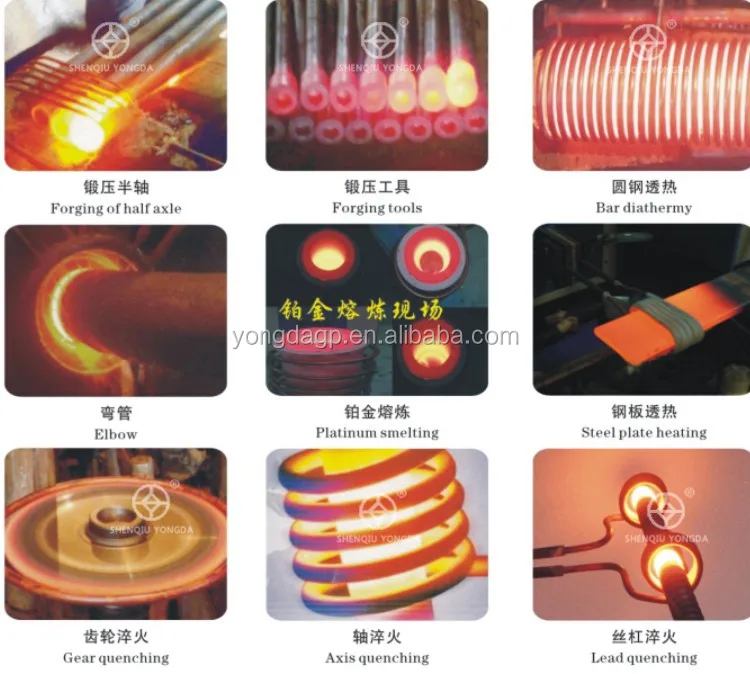

Applications of induction steel hardening furnace

Hardening is mainly through the process of heating the workpiece material hardness of the metal after making changes.Specific applications are as follows:

1, various hardware tools, hand tools. Such as pliers, wrench, hammer, ax, screwdriver, scissors (gardening scissors) and the quenching;

2, Various automotive, motorcycle accessories. Such as crankshaft, connecting rod, piston pin, wheel, aluminum wheels, valves, rocker shaft, drive axle, a small shaft, fork, etc. quenching;

3, various power tools. Such as gear, shaft;

4, the machine tool industry . Such as machine tool bed, Machine Tool, etc. quenching;

5, various hardware metal parts, machining parts. Such as shaft, gear (sprocket), cam, clamps, fixtures, etc. quenching;

6, the metal mold industries. Such as small mold, die attachment, die quenching the hole, etc.;

More application cases of steel hardening furnace

Debugging machine work shop

We are at oversea exhibition

Product quality certifications: ISO9001-2000

Packing for steel hardening furnace:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.