Brand Name: yongda

Model Number: WZP-36

Place of Origin: Henan, China (Mainland)

WZP-36 high frequency copper tube welding machine

This model is suitable for saw blades,turning tool,reamer,the impact of drilling,thin drill bit,pick,coal bit,welding of stainless steel products,small metal work parts heat treatment

Technical parameters of WZP-36 copper tube welding machine

| Model | Work power | Output power | Oscillation frequency | Output current | Cooling water pressure | Size | Weight |

| WZP-36 | three phase 380V+/-10% 50-60HZ | 3-20KW | 30-50KHZ | 2-36A | 0.1MPA | generator 410×290×500mm transformer 310×260×380mm |

22kgs; 18kgs |

Features of copper tube welding machine

1. IGBT modules, save energy than traditional high frequency tube heater.

2. Protect full.Over current.over voltage,lack of phase,water shortage, etc. more than ten alarm lamps.

3. Heating fast.Within1 second ,temperature rise up to 1200 degree,even higher.

4. No need contacting work pieces, safety, safe and reliable.

5. Environmental friendly,no pollution, good for worker's health

6. Easy to change induction coils, for heating different shape of steel billet

7. Easy to install and operate.

8. Low maintenance cost

Applications of copper tube welding machine

Welding, It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals of the same material or different materials.

1.Soldering of various hardware mechanical parts: Silver soldering and brazing of metals of the same variety or different varieties, such as hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

2. Soldering of various hardware cutting tools, such as diamond tool, abrasive tool, drilling tool, alloy saw blade, hard alloy cutter, milling cutter, reamer, planning tool and solid center bit.

3. Soldering of heating disc of electric hot-water kettle mainly refers to the braze welding of stainless steel flat base, aluminum sheet and tubular electric heating elements of various forms.

4. Compound pot bottom welding is mainly applicable to the braze welding of circular, square as well as other irregular plain pot bottom. It is also applicable to plain braze welding of other metals.

5, electric kettle (electric coffee pot) of hot plate welding is mainly used for stainless steel flat bottom, aluminum pipe with a variety of shapes between the electric soldering.

6.the soldering of various metal cutting tools: diamond cutting tools, grinding tools, drilling tools, alloy saw blade, carbide turning tools, milling cutters, reamers, planer, drill bits and other woodworking welding

7.the welding of various metal machinery parts: hardware bathroom products, refrigeration copper fittings, lighting accessories, precision mold parts, metal handle, mixer, alloy steel and steel, steel and copper, copper and copper equivalent or dissimilar metals Metallic silver, brazing;

8.Mining tools, welding, such as "one " bits, pillar gear drill bits, dovetail coal drill bits, drill rods riveting, all kinds of shearer, boring machine pick a variety of welding

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-36 |

320-420V |

2-36A |

30-50KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

Packing for cooper welding machine

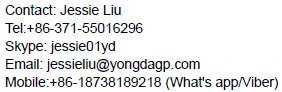

Copper tube welding machine, induction brazing welding machine, welcome to contact us :