Brand Name: Yongda

Model Number: WZP-120KW

Place of Origin: Henan, China (Mainland)

High quality induction heating drill bits hard alloy welding equipment with engineers service available overseas

What are the super advantages of high frequency induction heating welding equipment?

1.The lock-in technique using digital lock-in technique to achieve frequency automatic tracking, and can automatically adapt to a variety of sensors

2.Divided machine designment, including main machine and transformer.

3.The operation is simple, safe, reliable, and no high pressure dangerous.

4.Simple installation , you just need to link power and water .

5.24 hours continuous use, high efficiency and energy saving

6.Heating fast, high efficiency and heating evenly.

7.Nearly no oxidation layer

What is the technical parameter of the high frequency induction heating welding equipment ?

Model |

WZP-200/120KW |

Work power: |

3 phase 380V+/-10%, 50-60HZ |

Input voltage: |

320V-420V |

Input current: |

6-200A |

Oscillation frequency: |

15-30khz |

Cooling water pressure |

0.3 MPA |

Size of generator: |

850*600*1330mm |

Size of transformer |

780*540*520mm |

Weight of generator |

131kgs |

Weight of transformer |

89kgs |

Control panel functions:

Over voltage, over current, overheating, lack of water and other alarm indicator, and automatic control and protection .

Wha are the high frequency induction heating welding equipment applied to ?

1. metal tube welding:

such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

2. alloy cutter welding:

such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

3. carbide saw blade welding:

diamond saw blade welding, marble saw blade welding,woodworking saw blade welding,cut grass piece of welding, cut aluminum welding,

4. metal welding:

such as: towel rack, soap nets, towel holder, auto-accessories,moto accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

We are at induction heating welding equipment exhibition

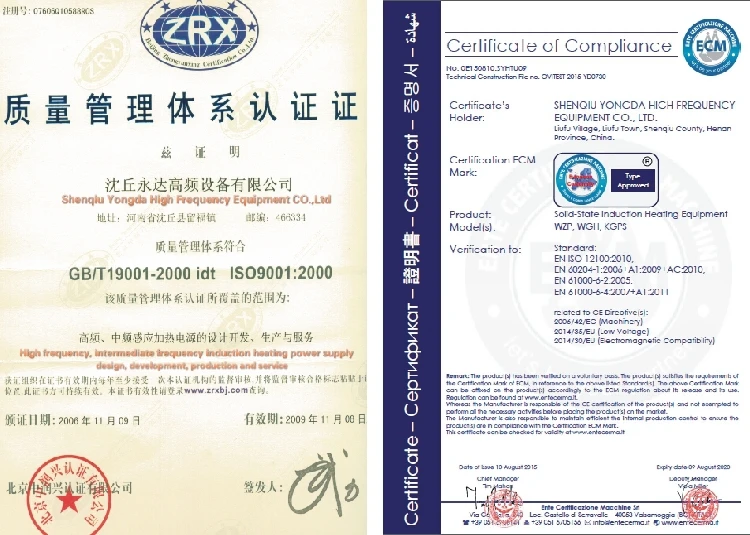

ISO and CE certificate

What are the high frequency induction heating welding equipment packing to ?

1. On the outside, packing fumigation wooden cases for welding for induction heating power supply.

2. Inside part, packing plastic film, in case friction of welding for induction heating power supply.

3. Induction coil is packaged inside.

4. heating power supply can be transported by ship air or train.

5. We provide 12 months spare part free replacement for welding for induction heating power supply

6. We also provide a induction coil, a foot pedal and a operation instruction along with each machine for free

What are the high frequency induction heating welding equipment services to ?

Equipment 12 months free replacement spare parts

Provide long-terms technical support with video, picture,telephone, email etc.

Installing and operating instructions is available.

Transport by sea, by air,by DHL

Hs code: 8514400090

Documents like certificate of Origin , FORM F, FORM E can be provided.

Payment terms, T/T ,L/C Cash etc , can be discussed