Brand Name: yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

shenqiu yongda igbt induction welding machine with CE

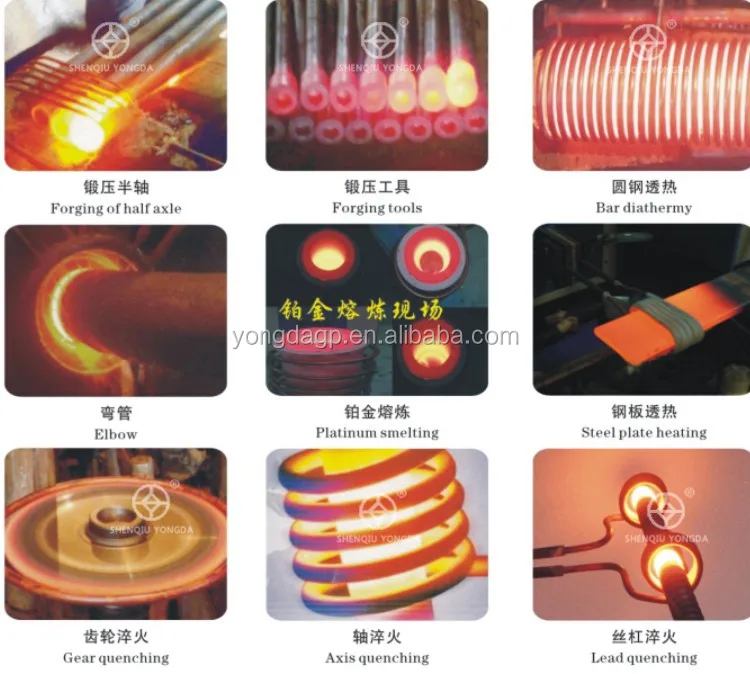

Heating/Hot Forging:

Aims to fabricate the work pieces of certain temperature into other shapes through forging press

with the help of punch press, forging machine or other equipments. for instances, hot extrusion of

watch case, watch flan, handle, mold accessory, kitchen and table ware, art ware, standard part, fastener,

fabricated mechanical part, bronze lock, rivet, steel pin and pin.

Quenching/Hardening:

I Metal quenching refers to one treatment method performed on metal workpieces that to chill the metal workpieces

drastically (for example, dabble towards metal workpieces rapidly or put them into oil) so as to improve the metal

hardness when they are heated to a certain temperature . Most of the workpieces are just needed for sacrificial quenching

or partial quenching; it is especially fit for induction heating equipment. For example, these are wheel gears, chain wheels,

leading axles, leading rails, jags, utility knives, rollers, cutting tools, machine tool accessories and moulds, and so forth.

Welding/Brazing:

It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals

of the same material or different material .For example, these are air-conditioner parts, copper fittings in a bathroom, furniture ,

decorative lighting, cutters, the bottom of a pan with mixed materials, electric kettles , and cemented carbide articles, such as wood

cutting tools, abrasive wheels, scrapers, and saw bits, and so forth.

Melting:

Mainly aims to melt the metal into liquid by using the high temperature, which is mainly

applicable to smelting of iron, steel, copper, aluminum, zinc as well as various precious

metals;In general, it utilizes series of power frequency, intermediate frequency and

ultrasonic frequency.

Annealing:

Annealing of various stainless steel products and other work pieces , such as stainless

steel basin, stainless steel tube, cue ,brass lock, aluminum radiator and so on .

The main technical parameters of igbt induction welding machine:

| Model | WZP-60 |

| work power | 3fases 380V+/-10%,50-60HZ |

| input voltage | 320V-420V |

| input current | 3-60A |

| oscillation frequency | 15-30KHZ |

| cooling water pressure | 0.1Mpa |

| size of generator | 590*330*650mm |

| size of transformer | 500*360*455mm |

| weight of generator | 41kgs |

| weight of transformer | 37kgs |

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs

to high-tech enterprise in Henan Province,China. We are located in Shenqiu County,

Zhoukou City. We professionally dedicated to R&D,production of HF,SSF,MF induction

heating equipment,adhering to the spirit of innovation, mean while strengthening

cooperation with domestic well-known universities and research institutions. We

are the leader of domestic induction heating field, and got the ISO9001:2000

international quality management system certification in August, 2004. Up to

now, we has 83 office in domestic ,products hot sale , and also exported to

Europe,America,and Southeast Asia etc. other regions.

Packing for high frequency induction heating machine:

Two wooden cases (plywood) Inside,will be filled with plastic foam,for waterproof and shockproof.

Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air.

1. Reply your inquiry within 24 working hours.

2. Experienced engineer instruct and sales communicate with you in fluent English.

3. According to work pieces specifications, heating requirements, propose best solutions,also reference your ideas.

4. Machine details and working video link for your reference.

5. Competitive price ,compare with the same industry.

6. Production: strict quality standard, to produce machine and induction coils.

7. Debugging machine and only good machine will be sent.

8. Tracking goods shipping and provide bill of lading,invoice,packing list and other documents what you need

9. Provide install and technology instruction by sending drawings, email, or telephone,video.

10.If you need, will arrange one engineer to your place,instruct install machine and training operators.

11.Excess warranty period(12 months warranty), you can buy the spare parts from us with special discount price.

12.Provide long-terms technical support.